Rule 3745-21-25 | Control of VOC emissions from reinforced plastic composites production operations.

[Comment: For dates and availability of non-regulatory government publications, publications of recognized organizations and associations, federal rules, and federal statutory provisions referenced in this rule, see paragraph (JJ) of rule 3745-21-01 of the Administrative Code titled "referenced materials."]

(A) Applicability.

(1) Except as otherwise provided in paragraph (A)(2) of this rule, this rule shall apply to any facility that has reinforced plastic composites production operations.

(2) Excluded from this rule, except for the recordkeeping requirements specified under paragraphs (A)(2)(d) and (A)(2)(e) of this rule, are the following:

(a) Any facility that only repairs reinforced plastic composites. Repair includes the non-routine manufacture of individual components or parts intended to repair a larger item as defined in paragraph (GG) of rule 3745-21-01 of the Administrative Code.

(b) Any facility that is a research and development facility as defined under section 3704.01 of the Revised Code.

(c) The production of any reinforced plastic composite that is used in the manufacturing of fiberglass boats within the facility.

(d) Any facility in which the reinforced plastic composites operations not otherwise excluded under paragraphs (A)(2)(a) to (A)(2)(c) of this rule use less than 1.2 tons per year of thermoset resins and gel coats that contain styrene combined. The owner or operator of such facility shall maintain records of the amount (in pounds) of thermoset resins and gel coats used each month that contain styrene. These records shall be retained by the owner or operator for a period of not less than five years and shall be made available to the director or any authorized representative of the director for review during normal business hours.

(e) Any facility that has a potential to emit for VOC of less than 10.0 tons per year for all reinforced plastic composites production operations combined. The owner or operator of such facility shall maintain an up-to-date record of the potential to emit for VOC from all reinforced plastic composites production operations, shall employ emission factors or emission estimates in the calculation of the potential to emit that meet paragraph (E) of this rule, shall maintain the records specified in paragraph (P)(2) of this rule for any sheet molding compound manufacturing machine, and within fifteen days after the end of each month, and shall maintain a record of the VOC emissions from any SMC manufacturing machine for the recent month and the rolling twelve-month period. However, this exclusion is not available for any facility that has, or once had, a potential to emit for VOC equal to or greater than 10.0 tons per year for all reinforced plastic composites production operations combined on or after December 14, 2010.

(3) Upon achieving compliance with this rule, the reinforced plastic composites production operations at the facility are not required to meet rule 3745-21-07 of the Administrative Code.

(B) Definitions.

The definitions applicable to this rule are contained in paragraphs (A), (B) and (GG) of rule 3745-21-01 of the Administrative Code.

(C) Affected operations.

(1) Except as otherwise provided in paragraphs (C)(2) and (C)(3) of this rule, the affected operations consist of all parts of the reinforced plastic composites production facility engaged in the following operations:

(a) Open molding.

(b) Compression/injection molding.

(c) Centrifugal casting.

(d) Continuous lamination.

(e) Continuous casting.

(f) Polymer casting.

(g) Pultrusion.

(h) Sheet molding compound (SMC) manufacturing.

(i) Bulk molding compound (BMC) manufacturing.

(j) Mixing.

(k) Cleaning of equipment used in reinforced plastic composites manufacture.

(l) VOC-containing materials storage.

(m) Repair operations on reinforced plastic composites parts that are manufactured at the facility.

(2) The following operations and materials are specifically excluded from in this rule:

(a) Application of mold sealing and release agents.

(b) Mold stripping and cleaning.

(c) Repair of reinforced plastic composites parts that the facility did not manufacture, including non-routine manufacturing of parts.

(d) Personal activities that are not part of the manufacturing operations (such as hobby shops on military bases).

(e) Prepreg materials.

(f) Non-gel coat surface coatings.

(g) Application of putties, polyputties, and adhesives.

(h) Repair or production materials that do not contain resin or gel coat.

(i) Research and development operations as defined under section 3704.01 of the Revised Code.

(j) Polymer casting.

(k) Any closed molding operation other than compression/injection molding (for example, resin transfer molding).

[Note: The exclusion of certain operations from this rule applies only to operations specifically listed in this paragraph. This rule still applies to any co-located operations. For example, although polymer casting and resin transfer molding operations are specifically excluded from this rule, any gel coating, mixing, VOC-containing materials storage, or cleaning operation associated with a polymer casting operation or a resin transfer molding operation is still subject to this rule.]

(3) Production resins that shall meet military specifications are allowed to meet the monomer content limit contained in that specification. In order for this exemption to be used, the owner or operator shall supply to the appropriate Ohio EPA district office or local air agency the specifications certified as accurate by the military procurement officer, and those specifications shall state a requirement for a specific resin, or a specific resin monomer content. Production resins for which this exemption is used shall be applied with nonatomizing resin application equipment unless the owner or operator can demonstrate this is infeasible. The owner or operator shall keep a record of the resins for which the owner or operator is using this exemption.

(D) VOC control.

(1) The owner or operator of the reinforced plastic composites production facility shall meet the work practice standards in table 1 of this rule for affected operations.

(2) If the reinforced plastic composites production facility has VOC emissions less than the threshold of one hundred tons of VOC per year from the combination of all open molding, centrifugal casting, continuous lamination/casting, pultrusion, SMC manufacturing, mixing, and BMC manufacturing, the owner or operator shall meet the VOC emissions limits in table 2 of this rule. A facility's VOC emissions threshold shall be calculated in accordance with paragraph (F) of this rule.

(3) Except as provided in paragraph (D)(4) of this rule, if the reinforced plastic composites production facility has VOC emissions equal to or greater than the threshold of one hundred tons of VOC per year from the combination of all open molding, centrifugal casting, continuous lamination/casting, pultrusion, SMC manufacturing, mixing, and BMC manufacturing, the owner or operator shall reduce the total VOC emissions from these operations by at least ninety-five per cent by weight. As an alternative to meeting ninety-five per cent by weight, the owner or operator may meet the VOC emissions limits in table 3 of this rule. A facility's VOC emissions threshold shall be calculated in accordance with paragraph (F) of this rule.

(4) If the reinforced plastic composites production facility manufactures large reinforced plastic composites parts using open molding or pultrusion operations, the specific open molding and pultrusion operations used to produce large parts are not required to reduce VOC emissions by ninety-five weight per cent, but shall meet the emission limits in table 2 of this rule. A large open molding part is defined as a part that, when the final finished part is enclosed in the smallest rectangular six-sided box into which the part can fit, the total interior volume of the box exceeds two hundred fifty cubic feet, or any interior sides of the box exceed fifty square feet. A large pultruded part is a part that exceeds an outside perimeter of twenty-four inches or has more than three hundred fifty reinforcements.

(5) Once a reinforced plastic composites production facility equals or exceeds the one hundred tons of VOC per year threshold of paragraph (D)(3) of this rule on or after December 14, 2009, the facility is always subject to paragraph (D)(3) of this rule, except as otherwise provided in paragraph (D)(6) of this rule.

(6) In the event a reinforced plastic composites production facility equals or exceeds the one hundred tons of VOC per year threshold of paragraph (D)(3) of this rule on or after December 14, 2009, but reduces emissions to less than the one hundred tons of VOC per year threshold by no later than the compliance date of this rule, the facility is not subject to paragraphs (D)(3) of this rule. If such reinforced plastic composites production facility subsequently equals or exceeds the one hundred tons of VOC per year threshold of paragraph (D)(3) of this rule, then the facility becomes subject to paragraph (D)(3) of this rule.

(7) If the reinforced plastic composites production facility has repair operations subject to this rule, these repair operations shall meet table 1 and table 2 of this rule and are not required to meet the ninety-five per cent VOC emissions reduction requirement in paragraph (D)(3) of this rule.

(8) Except where exempted under paragraph (D)(9) of this rule, any owner or operator of a SMC manufacturing machine shall install and operate a VOC emission control system that reduces the VOC emissions from the SMC manufacturing machine by at least ninety-five per cent by weight (i.e., an overall control efficiency of at least ninety-five per cent by weight).

(9) Exempted from the requirement of paragraph (D)(8) of this rule is any uncontrolled SMC manufacturing machine with VOC emissions of less than 25.0 tons per rolling twelve-month period.

(10) If an add-on control device is used to comply with this rule, such add-on control device shall meet 40 CFR part 63, subpart SS. The owner or operator shall also establish each control device operating limit in 40 CFR part 63, subpart SS, that applies.

(11) Alternatives.

The provisions of paragraphs (D)(1) to (D)(10) of this rule shall not apply to any emissions unit that meets the following:

(a) The director has determined that best available technology for the emissions unit, as required by rule 3745-31-05 of the Administrative Code, is a control requirement or emission limitation that is either less stringent than or inconsistent with paragraph (D) of this rule. Best available technology shall be defined in accordance with division (F) of section 3704.01 of the Revised Code and, for purposes of this paragraph, shall provide, where an emission limitation is applicable, the lowest emission limitation that the emissions unit is capable of meeting by the application of control technology that is reasonably available considering technological and economic feasibility. Also, for an emissions unit located within an ozone nonattainment area, the best available technology determination shall comply with Section 193 (general savings clause) of the Clean Air Act.

(b) The USEPA has informed the Ohio EPA, in writing, prior to the issuance of a final permit-to-install for the emissions unit, that the agency has no objection to the issuance of the final permit and the control requirement or emission limitation specified therein.

(c) A final permit-to-install has been issued for the emissions unit pursuant to Chapter 3745-31 of the Administrative Code. The permit-to-install shall contain terms and conditions that specify the control requirement or emission limitation that is the basis for the director's best available technology determination for the emissions unit, as described in paragraph (D)(11)(a) of this rule, and the permit-to-install shall be issued by the Ohio EPA in a manner that makes the control requirement or emission limitation federally enforceable.

(d) USEPA has approved the alternative limitation as a revision to the Ohio state implementation plan.

(E) Procedures for determination of VOC emissions factors for reinforced plastic composites production operations and determination of monomer content of resins and gel coats.

(1) Emissions factors are used in this rule to determine compliance with certain VOC emissions limits in table 2 and table 3 of this rule and to calculate VOC emissions. A person may use the equations in table 1 of 40 CFR part 63, subpart WWWW to calculate such emissions factors or may use any VOC emissions factor approved by USEPA, such as emission factors or emission factor equations from AP-42. These equations and emissions factors are intended to provide a method for one to demonstrate compliance without the need to conduct a VOC emissions test. In lieu of these equations and emissions factors, the owner or operator can elect to use site-specific VOC emissions factors to demonstrate compliance and to calculate VOC emissions provided the site-specific VOC emissions factors are incorporated in the facility's air emissions permit and are based on actual facility VOC emissions test data using the test procedures in 40 CFR 63.5850 or paragraph (C) of rule 3745-21-10 of the Administrative Code. Stack test data for the facility shall supersede emission factors and other emission estimating techniques.

(2) In order to determine the monomer content of resins and gel coats, the owner or operator may rely on information provided by the material manufacturer, such as manufacturer's formulation data and material safety data sheets (MSDS), using the procedures specified in paragraphs (E)(2)(a) to (E)(2)(c) of this rule, as applicable.

(a) Include in the total monomer content each monomer compound that is present at 0.1 per cent by mass or more for OSHA-defined carcinogens, as specified in paragraph A.6.4.1 of 29 CFR 1910.1200, appendix A and at 1.0 per cent by mass or more for other monomer compounds.

(b) If the monomer content is provided by the material supplier or manufacturer as a range, the owner or operator shall use the upper limit of the range for determining compliance. If a separate measurement of the total monomer content, such as an analysis of the material by USEPA method 311 of 40 CFR part 63, appendix A, exceeds the upper limit of the range of the total monomer content provided by the material supplier or manufacturer, then the owner or operator shall use the measured monomer content to determine compliance.

(c) If the monomer content is provided as a single value, the owner or operator may use that value to determine compliance. If a separate measurement of the total monomer content is made and is less than two percentage points higher than the value for total monomer content provided by the material supplier or manufacturer, then the owner or operator still may use the provided value to demonstrate compliance. If the measured total monomer content exceeds the provided value by two percentage points or more, then the owner or operator shall use the measured total monomer content to determine compliance.

(F) Calculation of facility's VOC emissions threshold.

(1) To calculate the facility's VOC emissions threshold in tons per year for purposes of determining which requirements apply under paragraph (D) of this rule, the owner or operator shall use the procedures in either paragraph (F)(2) of this rule for new facilities prior to startup, or paragraph (F)(3) of this rule for existing facilities and new facilities after startup. A facility's VOC emissions threshold pertains to the following operations: open molding, centrifugal casting, continuous lamination/casting, pultrusion, SMC manufacturing, mixing, and BMC manufacturing. The owner or operator is not required to calculate or report emissions under this paragraph if the facility does not have any of those operations. However, emissions calculation and emission reporting procedures in other paragraphs of this rule still apply. For the facility's VOC emissions threshold, calculate VOC emissions prior to any add-on control device, and do not include VOC emissions from any resin or gel coat used in operations subject to the boat manufacturing NESHAP, 40 CFR part 63, subpart VVVV, or from the manufacture of large parts as defined in paragraph (D)(4) of this rule. A "new facility" means a facility that has one or more operations specified in paragraph (F)(1) of this rule in which all such operations have a startup on or after December 14, 2009. An "existing facility" means a facility that has one or more operations specified in paragraph (F)(1) of this rule in which and at least one such operation has a startup prior to December 14, 2009.

(2) For new facilities prior to startup, the owner or operator shall calculate a weighted average VOC emissions factor for the operations specified in paragraph (F)(1) of this rule on a pounds of VOC per ton of resin, monomer, or gel coat basis. Base the weighted average on the projected operation for the twelve months subsequent to facility startup. Multiply the weighted average VOC emissions factor by projected resin, monomer, or gel coat use over the same period. The owner or operator may calculate a VOC emissions factor based on the factors in table 1 of 40 CFR part 63, subpart WWWW, or may use any VOC emissions factor approved by USEPA, such as factors from AP-42, or VOC emissions test data from similar facilities. The organic HAP emissions factors in table 1 of 40 CFR part 63, subpart WWWW are equivalent to the VOC emissions factors for this rule.

(3) For existing facilities and new facilities after startup, the owner or operator may use the procedures in either paragraph (F)(3)(a), (F)(3)(b), or (F)(3)(c) of this rule for the operations specified in paragraph (F)(1) of this rule. If the emission factors for an existing facility have changed over the period of time prior to its initial compliance date due to incorporation of pollution-prevention control techniques, the existing facility may base the average emission factor on its operations as they exist on the compliance date. If an existing or new facility has accepted an enforceable permit limit that would result in less than one hundred tons per year (per rolling twelve-month period) of VOC measured prior to any add-on controls, and can demonstrate that it will operate at that level subsequent to the compliance date, it can be deemed to be below the one hundred tons per year threshold.

(a) Use a calculated emission factor.

Calculate a weighted average VOC emissions factor on a pounds per ton of resin, monomer, or gel coat basis. Base the weighted average on the prior twelve months of operation. Multiply the weighted average VOC emissions factor by resin, monomer, or gel coat use over the same period. The owner or operator may calculate this VOC emissions factor based on the equations in table 1 of 40 CFR part 63, subpart WWWW, or the owner or operator may use any VOC emissions factor approved by USEPA, such as emission factors or emission factor equations from AP-42, or site-specific VOC emissions factors if they are supported by VOC emissions test data. The organic HAP emissions factors in table 1 of 40 CFR part 63, subpart WWWW are equivalent to the VOC emissions factors for this rule.

(b) Conduct performance testing.

Conduct performance testing using the test procedures in 40 CFR 63.5850 or paragraph (C) of rule 3745-21-10 of the Administrative Code to determine a site-specific VOC emissions factor in units of pounds of VOC per ton of resin, monomer, or gel coat used. Conduct the test under conditions expected to result in the highest possible VOC emissions. Multiply this factor by annual resin, monomer, or gel coat use to determine annual VOC emissions. This calculation shall be repeated and reported annually.

(c) Pultrusion operations.

For pultrusion operations employing enclosures or resin injection (direct or preform) pursuant to paragraph (I)(5)(b) of this rule, actual emissions may be calculated as four tenths and one tenth, respectively, of open line emissions, where open line emissions are calculated as specified in air permits covering these operations.

(4) Existing facilities shall initially perform this calculation based on their twelve months of operation prior to December 14, 2009, and include this information with their applicability notification report. Existing facilities shall repeat the calculation based on their resin, monomer, and gel coat use in the twelve months prior to their compliance date, and submit this information with the initial compliance report.

(5) After the initial compliance date, existing and new facilities shall calculate VOC emissions over the twelve-month period ending June thirtieth or December thirty-first, whichever date is the first date following the compliance date specified in paragraph (R) of this rule. Subsequent calculations should cover the periods in the semiannual compliance reports.

(G) Options for meeting the VOC emissions limits for open molding and centrifugal casting operations.

The owner or operator shall use one of the following methods in paragraphs (G)(1) to (G)(4) of this rule to meet the VOC emissions limits for open molding or centrifugal casting operations specified in table 2 or table 3 of this rule. The owner or operator may use any control method that reduces VOC emissions, including reducing resin and gel coat monomer content, changing to nonatomized mechanical application, using covered curing techniques, and routing part or all of the VOC emissions to an add-on control. The owner or operator may use different compliance options for the different operations listed in table 2 or table 3 of this rule. The necessary calculations shall be completed within thirty days after the end of each month. The owner or operator may switch between the compliance options in paragraphs (G)(1) to (G)(4) of this rule. When the owner or operator changes to an option based on a twelve-month rolling average, the owner or operator shall base the average on the previous twelve months of data calculated using the compliance option the owner or operator is changing to, unless the owner or operator was previously using an option that did not require the owner or operator to maintain records of resin and gel coat use. In this case, the owner or operator shall immediately begin collecting resin and gel coat use data and demonstrate compliance twelve months after changing options.

(1) Demonstrate that an individual resin or gel coat, as applied, meets the applicable emission limit in table 2 or table 3 of this rule.

(a) Calculate the actual VOC emissions factor for each different process stream within each operation type. A process stream is defined as each individual combination of resin or gel coat, application technique, and control technique. Process streams within operations types are considered different from each other if any of the following four characteristics vary: the neat resin plus or neat gel coat plus monomer content, the gel coat type, the application technique, or the control technique. The owner or operator shall calculate VOC emissions factors for each different process stream by using the appropriate equations in table 1 of 40 CFR part 63, subpart WWWW for open molding and for centrifugal casting, or site-specific VOC emissions factors discussed in paragraph (E) of this rule. The emission factor calculation should include any and all emission reduction techniques used including any add-on controls. If vapor suppressants are used to reduce VOC emissions, the owner or operator shall determine the vapor suppressant effectiveness (VSE) by conducting testing according to the procedures specified in 40 CFR part 63, Subpart WWWW, appendix A. If an add-on control device is used to reduce VOC emissions, the owner or operator shall determine the add-on control factor by conducting capture and control efficiency testing using the procedures specified in 40 CFR 63.5850. The VOC emissions factor calculated from the equations in table 1 of 40 CFR part 63, subpart WWWW, or a site-specific emissions factor, is multiplied by the add-on control factor to calculate the VOC emissions factor after control. The add-on control factor used in the VOC emissions factor equations is calculated from the following equation:

Add-on Control Factor = 1 - (% Control Efficiency / 100)

where:

Per cent control efficiency = value calculated from VOC emissions test measurements made according to 40 CFR 63.5850.

(b) If the calculated emission factor is less than or equal to the appropriate emission limit, the owner or operator has demonstrated that this process stream complies with the emission limit in table 2 of this rule. It is not necessary that all process streams, considered individually, demonstrate compliance to use this option for some process streams. However, for any individual resin or gel coat being used, if any of the process streams that include that resin or gel coat are to be used in any averaging calculations described in paragraphs (G)(2) to (G)(4) of this rule, then all process streams using that individual resin or gel coat shall be included in the averaging calculations.

(2) Demonstrate that, on average, the individual VOC emissions limits for each unique combination of operation type and resin application method or gel coat type shown in table 2 of this rule that applies to the facility are met.

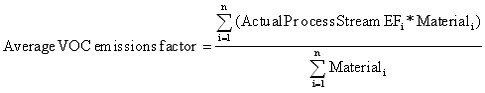

(a) Group the process streams described in paragraph (G)(1) of this rule by operation type and resin application method or gel coat type listed in table 2 of this rule and then calculate a weighted average emission factor based on the amounts of each individual resin or gel coat used for the last twelve months. To do this, sum the product of each individual VOC emissions factor calculated in paragraph (G)(1)(a) of this rule and the amount of neat resin plus and neat gel coat plus usage that corresponds to the individual factors and divide the numerator by the total amount of neat resin plus and neat gel coat plus used in that operation type as shown in the following equation:

where:

Actual Process Stream EFi = actual VOC emissions factor for process stream i, pounds of VOC per ton of neat resin plus or neat gel coat plus.

Materiali = the amount of neat resin plus or neat gel coat plus used during the last twelve calendar months for process stream i, tons.

n = number of process streams where the owner or operator calculated a VOC emissions factor.

(b) The owner or operator may, but is not required to, include process streams where the owner or operator has demonstrated compliance as described in paragraph (G)(1) of this rule, subject to the limitations described in paragraph (G)(1)(b) of this rule, and the owner or operator is not required to and should not include process streams for which the owner or operator will demonstrate compliance using the procedures in paragraph (G)(4) of this rule.

(c) Compare each VOC emissions factor calculated in paragraph (G)(2)(a) of this rule with its corresponding VOC emissions limit in table 2 or table 3 of this rule. If all emissions factors are equal to or less than the corresponding emission limits, then the operation is in compliance.

(3) Demonstrate compliance with a weighted average VOC emissions limit.

Demonstrate each month that each weighted average of the VOC emissions limits in table 2 or table 3 of this rule that apply are being met. When using this option, the owner or operator shall demonstrate compliance with the weighted average VOC emissions limit for all open molding operations, and then separately demonstrate compliance with the weighted average VOC emissions limit for all centrifugal casting operations. Open molding operations and centrifugal casting operations may not be averaged with each other.

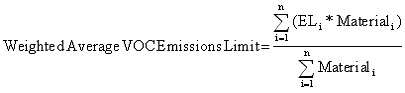

(a) Each month calculate the weighted average VOC emissions limit for all open molding operations and the weighted average VOC emissions limit for all centrifugal casting operations for the facility for the last twelve-month period to determine the VOC emissions limit the owner or operator shall meet. To do this, multiply the individual VOC emissions limits in table 2 or table 3 of this rule for each open molding (centrifugal casting) operation type by the amount of neat resin plus or neat gel coat plus used in the last twelve months for each open molding (centrifugal casting) operation type, sum these results, and then divide this sum by the total amount of neat resin plus and neat gel coat plus used in open molding (centrifugal casting) over the last twelve months as shown in the following equation:

where:

ELi = VOC emissions limit for operation type i, pounds per ton from table 2 or table 3 of this rule.

Materiali = amount of neat resin plus or neat gel coat plus used during the last twelve-month period for operation type i, tons.

n = number of operations.

(b) Each month calculate the weighted average VOC emissions factor for open molding and centrifugal casting. To do this, multiply the actual open molding (centrifugal casting) operation VOC emissions factors calculated in paragraph (G)(2)(a) of this rule and the amount of neat resin plus and neat gel coat plus used in each open molding (centrifugal casting) operation type, sum the results, and divide this sum by the total amount of neat resin plus and neat gel coat plus used in open molding (centrifugal casting) operations as shown in the following equation:

where:

Actual Operation EFi = Actual VOC emissions factor for operation type i, pounds of VOC per ton of neat resin plus or neat gel coat plus.

Materiali = amount of neat resin plus or neat gel coat plus used during the last twelve calendar months for operation type i, tons.

n = number of operations.

(c) Compare the values calculated in paragraphs (G)(3)(a) and (G)(3)(b) of this rule. If each twelve-month rolling average VOC emissions factor is less than or equal to the corresponding twelve-month rolling average VOC emissions limit, then the operation is in compliance.

(4) Meet the VOC emissions limit for one application method and use the same resins for all application methods of that resin type.

This option is limited to resins of the same type. The resin types for which this option may be used are noncorrosion-resistant, corrosion-resistant or high strength, and tooling.

(a) For any combination of manual resin application, mechanical resin application, filament application, or centrifugal casting, the owner or operator may elect to meet the VOC emissions limit for any one of these application methods and use the same resin in all of the resin application methods listed in this paragraph. Table 4 of this rule presents the possible combinations based on the owner or operator selecting the application process that results in the highest allowable monomer content resin. If the resin's monomer content is below the applicable value shown in the table 4 of this rule, the resin is in compliance.

(b) The owner or operator may also use a weighted average monomer content for each application method described in paragraph (G)(4)(a) of this rule. Calculate the weighted average monomer content monthly. Use the equation in paragraph (G)(2)(a) of this rule except substitute monomer content for VOC emissions factor. The operation is in compliance if the weighted average monomer content based on the last twelve months of resin use is less than or equal to the applicable monomer contents in the table 4 of this rule.

(c) The owner or operator may simultaneously use the averaging provisions in paragraph (G)(2) or (G)(3) of this rule to demonstrate compliance for any operations or resins the owner or operator does not include in the compliance demonstrations in paragraphs (G)(4)(a) and (G)(4)(b) of this rule. However, any resins for which the owner or operator claims compliance under the option in paragraphs (G)(4)(a) and (G)(4)(b) of this rule shall not be included in any of the averaging calculations described in paragraph (G)(2) or (G)(3) of this rule.

(d) The owner or operator does not have to keep records of resin use for any of the individual resins where the owner or operator demonstrates compliance under the option in paragraph (G)(4)(a) of this rule unless the owner or operator elects to include that resin in the averaging calculations described in paragraph (G)(4)(b) of this rule.

(H) Options for meeting the VOC emissions limits for continuous lamination/casting operations.

For continuous casting/lamination operations, the owner or operator shall use one or more of the options listed in paragraphs (H)(1) to (H)(4) of this rule to meet the VOC emissions limits specified in table 2 or table 3 of this rule and shall use the calculation procedures provided in paragraphs (J) to (M) of this rule.

(1) Compliant line option.

Demonstrate that each continuous lamination line and each continuous casting line complies with the applicable VOC emissions limit.

(2) Averaging option.

Demonstrate that all continuous lamination and continuous casting lines combined, comply with the applicable VOC emissions limit.

(3) Add-on control device option.

If the operation shall meet the 58.5 weight per cent VOC emissions reduction limit in table 2 of this rule, the owner or operator has the option of demonstrating that the operation achieves ninety-five per cent reduction of all wet-out area VOC emissions.

(4) Combination option.

Use any combination of options in paragraphs (H)(1) to (H)(3) of this rule.

(I) Options for meeting the standards for pultrusion operations subject to the sixty per cent by weight VOC emissions reductions requirement.

For pultrusion operations, the owner or operator shall use one or more of the options in paragraphs (I)(1) to (I)(5) of this rule to meet the sixty weight per cent VOC emissions limit in table 2 of this rule.

(1) Achieve an overall reduction in VOC emissions of sixty per cent by weight capturing the VOC emissions and venting them to a control device or any combination of control devices. Conduct capture and destruction efficiency testing as specified in 40 CFR 63.5850 to determine the per cent VOC emissions reduction.

(2) Design, install, and operate wet area enclosures and resin drip collection systems on pultrusion machines that meet the following:

(a) The enclosure shall cover and enclose the open resin bath and the forming area in which reinforcements are pre-wet or wet-out and moving toward the die. The surfaces of the enclosure shall be closed except for openings to allow material to enter and exit the enclosure.

(b) For open bath pultrusion machines with a radio frequency pre-heat unit, the enclosure shall extend from the beginning of the resin bath to within 12.5 inches or less of the entrance of the radio frequency pre-heat unit. If the stock that is within 12.5 inches or less of the entrance to the radio frequency pre-heat unit has any drip, it shall be enclosed. The stock exiting the radio frequency pre-heat unit is not required to be in an enclosure if the stock has no drip between the exit of the radio frequency pre-heat unit to within 0.5 inches of the entrance of the die.

(c) For open bath pultrusion machines without a radio frequency pre-heat unit, the enclosure shall extend from the beginning of the resin bath to within 0.5 inches or less of the die entrance.

(d) For pultrusion lines with pre-wet area prior to direct die injection, no more than 12.5 inches of open wet stock is permitted between the entrance of the first pre-wet area and the entrance to the die. If the pre-wet stock has any drip, it shall be enclosed.

(e) The total open area of the enclosure shall not exceed two times the cross sectional area of the puller window and shall comply with the following:

(i) All areas that are open need to be included in the total open area calculation with the exception of access panels, doors, or hatches that are part of the enclosure.

(ii) The area that is displaced by entering reinforcement or exiting product is considered open.

(iii) Areas that are covered by brush covers are considered closed.

(f) Open areas for level control devices, monitoring devices, agitation shafts, and fill hoses shall have no more than 1.0 inch clearance.

(g) The access panels, doors, or hatches that are part of the enclosure shall close tightly. Damaged access panels, doors, or hatches that do not close tightly shall be replaced.

(h) The enclosure may not be removed from the pultrusion line, and access panels, doors, or hatches that are part of the enclosure shall remain closed whenever resin is in the bath, except for the time period discussed in paragraph (I)(2)(i) of this rule.

(i) The maximum length of time the enclosure may be removed from the pultrusion line or the access panels, doors, or hatches and may be open, is thirty minutes per eight-hour shift, forty-five minutes per twelve-hour shift, or ninety minutes per day if the machine is operated for twenty-four hours in a day. The time restrictions do not apply if the open doors or panels do not cause the limit of two times the puller window area to be exceeded. Facilities may average the times that access panels, doors, or hatches are open across all operating lines. In that case the average shall not exceed the times shown in this paragraph. All lines included in the average shall have operated the entire time period being averaged.

(j) No fans, blowers, or air lines may be allowed within the enclosure. The enclosure shall not be ventilated.

(3) Use direct die injection pultrusion machines with resin drip collection systems that meet the following:

(a) All the resin that is applied to the reinforcement is delivered directly to the die.

(b) No exposed resin is present, except at the face of the die.

(c) Resin drip is captured in a closed system and recycled back to the process.

(4) Use a preform injection system that meets the definition in paragraph (GG) of rule 3745-21-01 of the Administrative Code.

(5) Use any combination of options in paragraphs (I)(1) to (I)(4) of this rule in which different pultrusion lines comply with different options described in paragraphs (I)(1) to (I)(4) of this rule, in addition to one of the following:

(a) Each individual pultrusion machine meets the sixty per cent reduction requirement.

(b) The weighted average reduction based on resin throughput of all pultrusion machines combined is sixty per cent. For purposes of the average per cent reduction calculation, wet area enclosures reduce VOC emissions by sixty per cent, and direct die injection and preform injection reduce VOC emissions by ninety per cent. For averaging purposes, zero reduction credit is earned during production on lines that have not installed and operated enclosures or injection systems as described in paragraphs (I)(2) to (I)(4) of this rule.

(J) Calculation of annual uncontrolled and controlled VOC emissions from wet-out areas and ovens for continuous lamination/casting operations.

To calculate the annual uncontrolled and controlled VOC emissions from the wet-out areas and from the ovens of continuous lamination/casting operations, the owner or operator shall develop uncontrolled and controlled wet-out area and uncontrolled and controlled oven VOC emissions estimation equations or factors to apply to each formula applied on each line, determine how much of each formula for each end product is applied each year on each line, and assign uncontrolled and controlled wet-out area and uncontrolled and controlled oven VOC emissions estimation equations or factors to each formula. The owner or operator shall determine the overall capture efficiency using the procedures in 40 CFR 63.5850.

(1) To develop uncontrolled and controlled VOC emissions estimation equations and factors, the owner or operator shall, at a minimum, do the following:

(a) Identify each end product and the thickness of each end product produced on the line. Separate end products into the following end product groupings, as applicable: corrosion-resistant gel coated end products, noncorrosion-resistant gel coated end products, corrosion-resistant non-gel coated end products, and noncorrosion-resistant non-gel coated end products. This step creates end product/thickness combinations.

(b) Identify each formula used on the line to produce each end product/thickness combination. Identify the amount of each such formula applied per year. Rank each formula used to produce each end product/thickness combination according to usage within each end product/thickness combination.

(c) For each end product/thickness combination being produced, select the formula with the highest usage rate for testing.

(d) If not already selected, also select the worst-case formula (likely to be associated with the formula with the highest monomer content, type of monomer, application of gel coat, thin product, low line speed, higher resin table temperature) amongst all formulae. (The owner or operator may use the results of the worst-case formula test for all formulae if desired to limit the amount of testing required.)

(e) For each formula selected for testing, conduct at least one test (consisting of three runs). During the test, track information on monomer content and type of monomer, end product thickness, line speed, and resin temperature on the wet-out area table.

(f) Using the test results, develop uncontrolled and controlled VOC emissions estimation equations (or factors) or series of equations (or factors) that best fit the results for estimating uncontrolled and controlled VOC emissions, taking into account the monomer content and type of monomer, end product thickness, line speed, and resin temperature on the wet-out area table.

(2) In lieu of using the method specified in paragraph (J)(1) of this rule for developing uncontrolled and controlled VOC emissions estimation equations and factors, the owner or operator may use either of the following methods:

(a) For either uncontrolled or controlled VOC emissions estimates, the owner or operator may use previously established, facility-specific VOC emissions equations or factors, provided the owner or operator allow estimation of both wet-out area and oven VOC emissions, where necessary, and have been approved by the appropriate Ohio EPA district office or local air agency. If a previously established equation or factor is specific to the wet-out area only, or to the oven only, then the owner or operator shall develop the corresponding uncontrolled or controlled equation or factor for the other VOC emissions source.

(b) For uncontrolled (controlled) VOC emissions estimates, the owner or operator may use controlled (uncontrolled) VOC emissions estimates and control device destruction efficiency to calculate the uncontrolled (controlled) VOC emissions provided the control device destruction efficiency was calculated at the same time the owner or operator collected the data to develop the facility's controlled (uncontrolled) VOC emissions estimation equations and factors.

(3) The owner or operator shall assign to each formula an uncontrolled VOC emissions estimation equation or factor based on the end product/thickness combination for which that formula is used.

(4) Calculation of annual uncontrolled and annual controlled VOC emissions from wet-out areas and ovens.

(a) To calculate the annual uncontrolled VOC emissions from wet-out areas that do not have any capture and control and from wet-out areas that are captured by an enclosure, but are vented to the atmosphere and not to a control device, multiply each formula's annual usage by its appropriate VOC emissions estimation equation or factor and sum the individual results.

(b) To calculate the annual uncontrolled VOC emissions that escape from the enclosure on the wet-out area, multiply each formula's annual usage by the appropriate uncontrolled VOC emissions estimation equation or factor, sum the individual results, and multiply the summation by one minus the per cent capture (expressed as a fraction).

(c) To calculate the annual uncontrolled oven VOC emissions, multiply each formula's annual usage by the appropriate uncontrolled VOC emissions estimation equation or factor and sum the individual results.

(d) To calculate the annual controlled VOC emissions, multiply each formula's annual usage by the appropriate VOC emissions estimation equation or factor and sum the individual results to obtain total annual controlled VOC emissions.

(5) Where a facility is calculating both uncontrolled and controlled VOC emissions estimation equations and factors, the owner or operator shall test the same formulae. In addition, the owner or operator shall develop both sets of equations and factors from the same tests.

(K) Determination of the capture efficiency of the enclosure on the wet-out area and the capture efficiency of the oven for continuous lamination/casting operations.

(1) The capture efficiency of a wet-out area enclosure is assumed to be one hundred per cent if it meets the design and operation requirements for a permanent total enclosure (PTE) specified in USEPA method 204 of 40 CFR part 51, appendix M. If a PTE does not exist, then a temporary total enclosure shall be constructed and verified using USEPA method 204, and capture efficiency testing shall be determined using USEPA methods 204B to E of 40 CFR part 51, appendix M.

(2) The capture efficiency of an oven is to be considered one hundred per cent, provided the oven is operated under negative pressure.

(L) Procedures to determine how much neat resin plus is applied to the line and how much neat gel coat plus is applied to the line for continuous lamination/casting operations.

Use the following procedures to determine how much neat resin plus and neat gel coat plus is applied to the line each year:

(1) Track formula usage by end product/thickness combinations.

(2) Use in-house records to show usage. This may be either from automated systems or manual records.

(3) Record daily the usage of each formula/end product combination on each line. This is to be recorded at the end of each run ( i.e., when a changeover in formula or product is made) and at the end of each shift.

(4) Sum the amounts from the daily records to calculate annual usage of each formula/end product combination by line.

(M) Calculation of per cent reduction to demonstrate compliance for continuous lamination/casting operations.

The owner or operator shall calculate per cent reduction for continuous lamination/casting operations using any of the following methods:

(1) Compliant line option.

If all of the wet-out areas have a PTE that meets USEPA method 204 of 40 CFR part 51, appendix M, and all of the wet-out area VOC emissions and oven VOC emissions are vented to an add-on control device, use the equation in paragraph (M)(1)(a) of this rule to demonstrate compliance. In all other situations, use the equation in paragraph (M)(1)(b) of this rule to demonstrate compliance.

(a)

PR = ((Inlet - Outlet) / Inlet) x 100

where:

PR = per cent reduction.

Inlet = VOC emissions entering the control device, pounds of VOC per year.

Outlet = VOC emissions exiting the control device to the atmosphere, pounds of VOC per year.

(b)

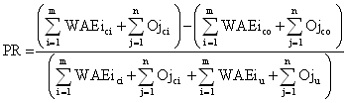

PR = (((WAEci + Oci) - (WAEco + Oco)) / (WAEci + WAEu + Oci + Ou)) x 100

where:

PR = per cent reduction.

Oci = oven VOC emissions, pounds of VOC per year, vented to a control device.

Oco = oven VOC emissions, pounds of VOC per year, from the control device outlet.

Ou = oven VOC emissions, pounds of VOC per year, not vented to a control device.

WAEci = wet-out area VOC emissions, pounds of VOC per year, vented to a control device.

WAEco = wet-out area VOC emissions, pounds of VOC per year, from the control device outlet.

WAEu = wet-out area VOC emissions, pounds of VOC per year, not vented to a control device.

(2) Averaging option.

Use the following equation to calculate per cent reduction:

where:

PR = per cent reduction.

Ojci = VOC emissions from oven j, pounds of VOC per year, sent to a control device.

Ojco = VOC emissions from oven j, pounds of VOC per year, at the outlet of the control device.

Oju = VOC emissions from oven j, pounds of VOC per year, not sent to a control device.

WAEici = wet-out area VOC emissions from wet-out area i, pounds of VOC per year, sent to a control device.

WAEico = wet-out area VOC emissions from wet-out area i, pounds of VOC per year, at the outlet of a control device.

WAEiu = wet-out area VOC emissions from wet-out area i, pounds of VOC per year, not sent to a control device.

m = number of wet-out areas.

n = number of ovens.

(3) Add-on control device option.

Use the equation in paragraph (M)(1)(a) of this rule to calculate per cent reduction.

(4) Combination option.

Use the equations in paragraphs (M)(1)(a), (M)(1)(b), and (M)(2) of this rule, as applicable, to calculate per cent reduction.

(N) Calculation of a VOC emissions factor to demonstrate compliance for continuous lamination/casting operations.

(1) Compliant line option.

Use the following equation to calculate a VOC emissions factor in pounds of VOC per ton of neat resin plus and neat gel coat plus.

E = (WAEu + WAEc + Ou + Oc ) / (R + G)

where:

E = VOC emissions factor in pounds of VOC per ton of neat resin plus and neat gel coat plus.

WAEu = uncontrolled wet-out area VOC emissions, pounds of VOC per year.

WAEc = controlled wet-out area VOC emissions, pounds of VOC per year.

Ou = uncontrolled oven VOC emissions, pounds of VOC per year.

Oc = controlled oven VOC emissions, pounds of VOC per year.

R = total usage of neat resin plus, tons per year.

G = total usage of neat gel coat plus, tons per year.

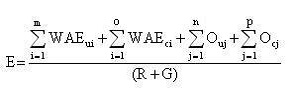

(2) Averaging option.

Use the following equation to demonstrate compliance:

where:

E = VOC emissions factor in pounds of VOC per ton of resin and gel coat.

WAEui = uncontrolled VOC emissions from wet-out area i, pounds of VOC per year.

WAEci = controlled VOC emissions from wet-out area i, pounds of VOC per year.

Ouj = uncontrolled VOC emissions from oven j, pounds of VOC per year.

Ocj = controlled VOC emissions from oven j, pounds of VOC per year.

i = number of wet-out areas.

j = number of ovens.

m = number of wet-out areas uncontrolled.

n = number of ovens uncontrolled.

o = number of wet-out areas controlled.

p = number of ovens controlled.

R = total usage of neat resin plus, tons per year.

G = total usage of neat gel coat plus, tons per year.

(3) Combination option.

Use the equations in paragraphs (N)(1) and (N)(2) of this rule, as applicable, to demonstrate compliance.

(O) Demonstration of continuous compliance and the associated monitoring and data collection requirements.

(1) Demonstration of continuous compliance.

(a) The owner or operator shall demonstrate continuous compliance with each VOC control requirement in paragraph (D) of this rule that applies to the affected operations according to the following methods:

(i) Compliance with VOC emissions limits for affected operations using add-on control devices is demonstrated by following the procedures in 40 CFR part 63, subpart SS, which include the use of continuous parameter monitors. Affected operations using add-on control devices may also use continuous emissions monitors to demonstrate continuous compliance as an alternative to continuous parameter monitors.

(ii) Compliance with VOC emissions limits is demonstrated by maintaining a VOC emissions factor value less than or equal to the appropriate VOC emissions limit listed in table 2 or table 3 of this rule, on a twelve-month rolling average, or by including in each compliance report a statement that individual resins and gel coats, as applied, meet the appropriate VOC emissions limits, as discussed in paragraph (O)(2)(c) of this rule.

(iii) Compliance with monomer content limits in table 4 of this rule is demonstrated by maintaining an average monomer content value less than or equal to the appropriate monomer contents listed in table 4 of this rule, on a twelve-month rolling average, or by including in each compliance report a statement that resins and gel coats individually meet the appropriate monomer content limits in table 4 of this rule, as discussed in paragraph (G)(4)(d) of this rule.

(iv) Compliance with the work practice standards in table 1 of this rule is demonstrated by performing the work practice required for the affected operation.

(b) The owner or operator shall report each deviation from each VOC control requirement in paragraph (D) of this rule that applies. The deviations shall be reported according to paragraph (Q) of this rule.

(c) Except as provided in paragraph (O)(1)(d) of this rule, during periods of startup, shutdown or malfunction, the owner or operator shall meet the VOC emissions limits and work practice standards that apply.

(d) When an add-on control device is used to meet a VOC control requirement in paragraph (D) of this rule, the owner or operator is not required to meet that VOC control requirement during periods of startup, shutdown, or malfunction, but the owner or operator shall operate the affected operation to minimize emissions to the greatest extent which is consistent with safety and good air pollution control practice.

(e) Deviations that occur during a period of malfunction for those affected operations and standards specified in paragraph (O)(1)(d) of this rule are not violations if the owner or operator demonstrates to the director's satisfaction that the owner or operator was operating in accordance with paragraph (O)(1)(d) of this rule. The director will determine whether deviations that occur during a period of startup, shutdown, and malfunction are violations.

(2) Monitoring and data collection requirements to demonstrate continuous compliance.

(a) If using an add-on control device, the owner or operator shall during production collect and keep a record of data as indicated in 40 CFR part 63, subpart SS and shall monitor and collect the following data:

(i) Except for monitoring malfunctions, associated repairs, and required quality assurance or control activities (including, as applicable, calibration checks and required zero and span adjustments), the owner or operator shall conduct all monitoring in continuous operation (or collect data at all required intervals) at all times that the controlled operation is operating.

(ii) The owner or operator may not use data recorded during monitoring malfunctions, associated repairs, and required quality assurance or control activities for purposes of this rule, including data averages and calculations, or fulfilling a minimum data availability requirement, if applicable. The owner or operator shall use all the data collected during all other periods in assessing the operation of the control device and associated control system.

(iii) At all times, the owner or operator shall maintain necessary parts for routine repairs of the monitoring equipment.

(iv) A monitoring malfunction is any sudden, infrequent, not reasonably preventable failure of the monitoring equipment to provide valid data. Monitoring failures that are caused in part by poor maintenance or careless operation are not malfunctions.

(b) For meeting any VOC emissions limits based on a VOC emissions limit specified in table 2 or table 3 of this rule, the owner or operator shall collect and keep records of resin and gel coat use, monomer content, and operation where the resin is used. If the owner or operator is averaging monomer contents to meet any monomer content limits specified in table 4 of this rule, the owner or operator shall collect and keep records of resin and gel coat use, monomer content, and operation where the resin is used. Resin use records may be based on purchase records if the owner or operator can reasonably estimate how the resin is applied. The monomer content records may be based on MSDS or on resin specifications supplied by the resin supplier.

(c) Resin and gel coat use records are not required for the individual resins and gel coats that are demonstrated, as applied, to meet their applicable emission limit as defined in paragraph (G)(1) of this rule. However, the owner or operator shall retain the records of resin and gel coat monomer content, and the owner or operator shall include the list of these resins and gel coats and identify their application methods in the semiannual compliance reports. If after the owner or operator has initially demonstrated that a specific combination of an individual resin or gel coat, application method, and controls meets an applicable emission limit, and the resin or gel coat changes or the monomer content increases, or the owner or operator changes the application method or controls, then the owner or operator again shall demonstrate that the individual resin or gel coat meets its emission limit as specified in paragraph (G)(1) of this rule. If any of the previously mentioned changes results in a situation where an individual resin or gel coat exceeds its applicable emission limit in table 2 or table 3 of this rule, the owner or operator shall begin collecting resin and gel coat use records and calculate compliance using one of the averaging options on a twelve-month rolling average.

(d) For each pultrusion machine, the owner or operator shall record all times that doors or covers of wet area enclosures are open and there is resin present in the resin bath.

(P) Recordkeeping.

(1) The owner or operator shall keep the following records:

(a) A copy of each applicability notification and compliance status report submitted to comply with this rule, including all documentation supporting any applicability or compliance status.

(b) For any add-on control device, all records required in 40 CFR part 63, subpart SS, to show continuous compliance with this rule.

(c) For operations listed in tables 2, 3, and 4 of this rule all data, assumptions, and calculations used to determine monomer contents and VOC emissions factors.

(d) For any continuous laminating/casting operation:

(i) All data, assumptions, and calculations used to determine monomer contents, VOC emissions factors, per cent reduction of VOC emissions, or pounds of VOC per ton as applicable.

(ii) A brief description of the rationale for the assignment of a VOC emissions equation or VOC emissions factor to each resin or gel coat formula.

(iii) When using facility-specific VOC emissions estimation equations or factors, all data, assumptions, and calculations used to derive the VOC emissions estimation equations and factors and identification and rationale for the worst-case resin or gel coat formula.

(iv) For all VOC emissions estimation equations and VOC emissions factors, documentation that USEPA has approved them. This requirement does not apply to VOC emissions estimation equations and VOC emissions factors found in table 1 of 40 CFR part 63, subpart WWWW or AP-42.

(e) A certified statement that operations are in compliance with the work practice standards specified in table 1 of this rule, as applicable.

(2) Regardless of any exclusion in paragraph (A)(2)(e) of this rule, the owner or operator of a SMC manufacturing machine shall keep the following records:

(a) Monthly production records of the following operational data for each SMC manufacturing machine:

(i) The amount of SMC produced for each type of SMC product.

(ii) The monomer content of each SMC product.

(b) Monthly VOC emissions records for each SMC manufacturing machine that show the VOC emissions factor used for each SMC product, including a citation of the source of the emission factor, and the results of the VOC emission calculations.

(3) For any uncontrolled SMC manufacturing machine exempted under paragraph (D)(9) of this rule, the owner or operator shall record the VOC emissions from that SMC manufacturing machine for the recent month and rolling twelve-month period within fifteen days after the end of each month. The owner or operator shall notify the appropriate Ohio EPA district office or local air agency of any record showing the SMC manufacturing machine exceeded the applicable VOC emissions limit. A copy of such record shall be sent to the appropriate Ohio EPA district office or local air agency within forty-five days after the exceedance occurs.

(4) All records specified under paragraphs (P)(1) to (P)(3) of this rule shall be retained by the owner or operator for a period of not less than five years following the date of each occurrence, measurement, maintenance, corrective action, report, or record and shall be made available to the director or any authorized representative of the director for review during normal business hours.

(Q) Reporting.

(1) The owner or operator of a facility that has reinforced plastic composites production operations subject to this rule shall submit semiannual compliance status reports containing the information specified in paragraphs (Q)(3)(a) to (Q)(3)(h) of this rule. The semiannual compliance status reports shall be submitted no later than thirty calendar days after the end of each six-month period to the appropriate Ohio EPA district office or local air agency. The first compliance report shall cover the period beginning on the compliance date that is specified in paragraph (R) of this rule and ending on June thirtieth or December thirty-first, whichever date is the first date following the end of the first calendar half after the compliance date that is specified in paragraph (R) of this rule. Each subsequent compliance report shall cover the semiannual reporting period from January first through June thirtieth or the semiannual reporting period from July first through December thirty-first.

(2) For each facility that is subject to permitting requirements pursuant to Chapter 3745-77 of the Administrative Code (pertaining to Title V permits), the owner or operator may submit the first and subsequent semiannual compliance reports according to the dates established within the facility's Title V permit, instead of according to the dates specified in paragraph (Q)(1) of this rule.

(3) The compliance report shall contain the following information:

(a) Company name and address.

(b) Statement by a responsible official with that official's name, title, and signature, certifying the truth, accuracy, and completeness of the content of the report.

(c) Date of the report and beginning and ending dates of the reporting period.

(d) If there are no deviations from any VOC emissions limitations and operating limits that apply and there are no deviations from the work practice standards in table 1 of this rule, a statement that there were no deviations from VOC emissions limitations, operating limits, or work practice standards during the reporting period.

(e) If there were no periods during which a continuous monitoring system (CMS), including a continuous emissions monitoring system and a continuous parameter monitoring system, were out of control, a statement that there were no periods during which the CMS was out of control during the reporting period.

(f) For each deviation from a VOC emissions limitation or operating limit and for each deviation from a work practice standard that occurs at an affected operation where a CMS is not used to comply with the VOC emissions limitation, operating limit, or work practice standard in this rule, the compliance report shall contain the following information:

(i) The total operating time of each affected operation during the reporting period.

(ii) Information on the number, duration, and cause of deviations (including unknown cause, if applicable), as applicable, and the corrective action taken.

(g) For each deviation from an VOC emissions limitation or operating limit that occurs at an affected operation where a CMS is used to comply with the VOC emissions limitation or operating limit in this rule, the compliance report shall include the following information:

(i) The date and time that each malfunction started and stopped.

(ii) The date and time that each CMS was inoperative, except for zero (low-level) and high-level checks.

(iii) The date, time, and duration that each CMS was out of control, as defined in paragraph (c)(7) of 40 CFR 63.8, including the information in paragraph (c)(8) of 40 CFR 63.8.

(iv) The date and time that each deviation started and stopped, and whether each deviation occurred during a period of startup, shutdown, or malfunction, or during another period.

(v) A summary of the total duration of the deviation during the reporting period and the total duration as a per cent of the total source operating time during that reporting period.

(vi) A breakdown of the total duration of the deviations during the reporting period into those that are due to startup, shutdown, control equipment problems, process problems, other known causes, and other unknown causes.

(vii) A summary of the total duration of CMS downtime during the reporting period and the total duration of CMS downtime as a per cent of the total source operating time during that reporting period.

(viii) An identification of each VOC that was monitored at the affected source.

(ix) A brief description of the affected operations.

(x) A brief description of the CMS.

(xi) The date of the latest CMS certification or audit.

(xii) A description of any changes in CMS, processes, or controls since the last reporting period.

(h) Where multiple compliance options are available, the owner or operator shall state in this compliance report if the owner or operator has changed compliance options since the last compliance report.

(4) The owner or operator shall report if the facility exceeded the one hundred tons of VOC per year emissions threshold if that exceedance would make the facility subject to paragraph (D)(3) of this rule.

(5) Each facility that has obtained a Title V permit pursuant to Chapter 3745-77 of the Administrative Code shall report all deviations as described in this rule in the semiannual monitoring report required by the Title V permit. If the facility submits a semiannual compliance report pursuant to this rule along with, or as part of, the semiannual monitoring report required by the facility's Title V permit, and the semiannual compliance report includes all required information concerning deviations from any VOC emissions limitation, operating limit, or work practice standard in this rule, submission of the semiannual compliance report shall be deemed to satisfy any obligation to report the same deviations in the semiannual monitoring report. However, submission of a compliance report shall not otherwise affect any obligation the affected source may have to report deviations from permit requirements to the appropriate Ohio EPA district office or local air agency.

(R) Compliance dates.

(1) Except where otherwise specified within this rule, any owner or operator of an affected operation that is subject to this rule shall comply with this rule by no later than the following dates:

(a) For any affected operation for which installation commenced before December 14, 2009, the compliance date of the affected operation is the initial startup of the affected operation or December 14, 2010, whichever is later.

(b) For any affected operation for which installation commenced on or after December 14, 2009, the compliance date of the affected operation is the date of initial startup of the affected operation.

(2) If the reinforced plastic composites production facility has VOC emissions less than the threshold of one hundred tons of VOC per year from the combination of all open molding, centrifugal casting, continuous lamination/casting, pultrusion, SMC manufacturing, mixing, and BMC manufacturing, and the facility subsequently increases VOC emissions to meet or exceed the threshold of one hundred tons of VOC per year from the combination of such operations, the compliance date of any affected operation pertaining to a new VOC emission requirement is two years from the date that the semiannual compliance report indicates the facility meets or exceeds the threshold of one hundred tons of VOC per year.

(3) In the event an uncontrolled SMC manufacturing machine is exempted under paragraph (D)(9) of this rule and is later equipped with a VOC emission control system, the compliance date of the SMC manufacturing machine pertaining to paragraph (D)(8) of this rule is the date of first startup of the installed VOC emission control system for the SMC manufacturing machine. Until the date of first startup of the installed VOC emission control system for the SMC manufacturing machine, the SMC manufacturing machine shall continue to comply with paragraph (D)(9) of this rule.

(4) If an affected operation is vented to an add-on control to meet a VOC emissions requirement specified within the rule, the owner or operator shall demonstrate compliance by testing the operation and the add-on control device in accordance with this rule within ninety days after the compliance date of the affected operation.

(5) Additional testing of an affected operation vented to an add-on control may be required by the director to ensure continued compliance.

(S) Applicability notification, permit application, and testing notification.

(1) The owner or operator of an affected operation, as described in paragraph (C) of this rule, that is subject to this rule and that has an initial startup date before December 14, 2009 shall notify the appropriate Ohio EPA district office or local air agency in writing that such operation is subject to this rule. The notification, which shall be submitted not later than February 12, 2010, shall provide the following information:

(a) Name and address of the owner or operator.

(b) Address (i.e., physical location) of the facility.

(c) Equipment description and Ohio EPA application number (if assigned) of the affected operation.

(d) Identification of the applicable requirements, the means of compliance, and the compliance date for the affected operation under this rule.

(e) An application for an operating permit or an application for a modification to an operating permit in accordance with Chapter 3745-77 of the Administrative Code (for sources subject to the Title V permit program) or an application for a permit-to-install and operate or an application for a modification to a permit-to-install and operate in accordance with Chapter 3745-31 of the Administrative Code (for sources not subject to the Title V permit program) for each subject process that meets one of the following:

(i) The process does not possess an effective operating permit or permit-to-install and operate.

(ii) The process possesses an effective operating permit or permit-to-install and operate and the owner or operator cannot certify in writing to the director that such subject process is in compliance with this rule. An application for an operating permit or permit-to-install and operate is not required provided the subject process is operating under an effective permit and certifies compliance. Such certification shall include all compliance certification requirements under paragraph (Q)(3) of this rule.

(2) The owner or operator of an affected operation, as described in paragraph (C) of this rule, that is subject to this rule and that has an initial startup date on or after December 14, 2009 shall notify the appropriate Ohio EPA district office or local air agency in writing that the affected operation is subject to this rule. The notification, which shall be submitted not later than either the date of initial startup of the affected operation or February 12, 2010, whichever is later, shall provide the information listed under paragraph (F)(1) of this rule. The application for a permit to install under rule 3745-31-02 of the Administrative Code may be used to fulfill the notification requirements of this paragraph.

(3) For the compliance testing of an affected operation that is vented to an add-on control device to meet a VOC emissions requirement specified within this rule, the owner or operator shall submit an intent to test that is in accordance with the procedures of paragraph (A) of rule 3745-21-10 of the Administrative Code and that includes the test procedures specified within this rule.

| Type of operation | Work practice standards |

| 1. Compression/injection molding | Uncover, unwrap or expose only one charge per mold cycle per compression/injection molding machine. For machines with multiple molds, one charge means sufficient material to fill all molds for one cycle. For machines with robotic loaders, no more than one charge may be exposed prior to the loader. For machines fed by hoppers, sufficient material may be uncovered to fill the hopper. Hoppers shall be closed when not adding materials. Materials may be uncovered to feed to slitting machines. Materials shall be recovered after slitting. |

| 2. Cleaning operation (cleaning of equipment used in reinforced plastic composites manufacture) | Do not use cleaning solvents (cleaners) that have a VOC content greater than 0.42 pound VOC per gallon, except cleaners used in closed systems and used to clean cured resin from application equipment. Application equipment includes any equipment that directly contacts resin. |

| 3. VOC-containing materials storage operation | Keep containers that store VOC-containing materials closed or covered except during the addition or removal of materials. Bulk VOC-containing materials storage tanks may be vented as necessary for safety. |

| 4. SMC manufacturing operation | a. Close or cover the resin delivery system to the doctor box on each SMC manufacturing machine. The doctor box itself may be open. |

| b. Use a nylon containing film to enclose SMC. | |

| 5. All mixing or BMC manufacturing operations1 | a. Use mixer covers with novisible gaps present in the mixer covers, except that gaps of up to 1.0 inch are permissible around mixer shafts and any required instrumentation. |

| b. Close any mixer vents when actual mixing is occurring, except that venting is allowed during addition of materials, or as necessary prior to adding materials or opening the cover for safety. Vents routed to a ninety-five per cent efficient control device are exempt from this requirement. | |

| c. Keep the mixer covers closed while actual mixing is occurring except when adding materials or changing covers to the mixing vessels. | |

| 6. Pultrusion operation manufacturing parts that meet the following criteria: one thousand or more reinforcements or the glass equivalent of one thousand ends of one hundred thirteen yield roving or more; and have a cross-sectional area of sixty square inches or more that is not subject to the ninety-five per cent VOC emissions reduction requirement | a. Do not allow vents from the building ventilation system, or local or portable fans to blow directly on or across the wet-out area. |

| b. Do not permit point suction of ambient air in the wet-out area unless that air is directed to a control device. | |

| c. Use devices such as deflectors, baffles, and curtains when practical to reduce air flow velocity across the wet-out area. | |

| d. Direct any compressed air exhausts away from resin and wet-out area. | |

| e. Convey resin collected from drip-off pans or other devices to reservoirs, tanks, or sumps via covered troughs, pipes, or other covered conveyance that shields the resin from the ambient air. | |

| f. Cover all reservoirs, tanks, sumps, or VOC-containing materials storage vessels except when they are being charged or filled. | |

| g. Cover or shield from ambient air resin delivery systems to the wet-out area from reservoirs, tanks, or sumps where practical. |

1Containers of five gallons or less may be open when active mixing is taking place, or during periods when they are in process (i.e., they are actively being used to apply resin). For polymer casting mixing operations, containers with a surface area of five hundred square inches or less may be open while active mixing is taking place.

| Type of operation | Resin application method or gel coat type | VOC emissions limit1 |

| 1. Open molding: corrosion-resistant and/or high strength (CR/HS) | a. Mechanical resin application | 113 lb/ton |

| b. Filament application | 171 lb/ton | |

| c. Manual resin application | 123 lb/ton | |

| 2. Open molding: non-CR/HS | a. Mechanical resin application | 88 lb/ton |

| b. Filament application | 188 lb/ton | |

| c. Manual resin application | 87 lb/ton | |

| 3. Open molding: tooling | a. Mechanical resin application | 254 lb/ton |

| b. Manual resin application | 157 lb/ton | |

| 4. Open molding: low-flame spread/low-smoke products | a. Mechanical resin application | 497 lb/ton |

| b. Filament application | 270 lb/ton | |

| c. Manual resin application | 238 lb/ton | |

| 5. Open molding: shrinkage controlled resins2 | a. Mechanical resin application | 354 lb/ton |

| b. Filament application | 215 lb/ton | |

| c. Manual resin application | 180 lb/ton | |

| 6. Open molding: gel coat3 | a. Tooling gel coat | 440 lb/ton |

| b. White/off white pigmented gel coat | 267 lb/ton | |

| c. All other pigmented gel coat | 377 lb/ton | |

| d. CR/HS or high performance gel coat | 605 lb/ton | |

| e. Fire retardant gel coat | 854 lb/ton | |

| f. Clear production gel coat | 522 lb/ton | |

| 7. Centrifugal casting: CR/HS | a. Resin application with the mold closed, and the mold is vented during spinning and cure | 25 lb/ton4 |

| b. Resin application with the mold closed, and the mold is not vented during spinning and cure | Not applicable (this is considered to be a closed molding operation) | |