[Comment: For the definitions of terms used in this rule, see rule 3745-42-01 of the Administrative Code.]

[Comment: For dates of non-regulatory government publications, publications of recognized organizations and associations, federal rules and federal statutory provisions referenced in this rule, see rule 3745-42-01 of the Administrative Code.]

(A) Land application systems: purpose.

The purpose of this rule is to establish permit application requirements, design standards, siting restrictions, operation and maintenance requirements and water quality and monitoring frequency requirements for land application systems as part of the director's supervision of the installation and operation and maintenance of this type of sewage or liquid industrial waste disposal system. Portions of this rule may apply for liquid industrial wastes land applied for agronomic benefit. For the purposes of this rule, a liquid industrial waste agronomic benefit shall provide for organic or nutrient enrichment of soil for plant growth. The director may waive any requirement in paragraph (H), (L), or (M) of this rule for any land application system where the treatment works is designed for less than one thousand gallons per day.

(B) Land application systems: exclusions. This rule does not apply to the following:

(1) Soil absorption systems. Examples of soil absorption systems are as follows:

(a) Conventional leach fields.

(b) Mound systems.

(c) Below grade low pressure pipe distribution systems, including drip distribution systems.

(d) At-grade gravity leach field dispersal systems.

(2) The land application of domestic, commercial or industrial septage.

(3) The land application of industrial waste, unless the waste is liquid and provides an agronomic benefit.

(4) The land application of grease from an internal grease trap or an external grease interceptor.

(C) Land application systems: prohibitions and restrictions.

(1) The land application of untreated sewage is prohibited.

(2) No person shall land apply treated sewage or liquid industrial wastes as follows:

(a) To natural wetlands or to constructed wetlands, unless approved by Ohio EPA. The director may require an isolation distance from natural or constructed wetlands to protect public health or the environment.

(b) Within the ten-year floodplain. The director may prohibit the land application of treated sewage or liquid industrial waste beyond the ten-year flood plain in order to protect public health or the environment.

(c) During a precipitation event, or when the forecast indicates that there is at least a fifty per cent chance that 0.5-inch of rain will occur within twenty-four hours after land application, unless permitted by a national pollutant discharge elimination system (NPDES) permit.

(d) On snow covered ground, unless permitted by an NPDES permit.

(e) On frozen ground, unless permitted by an NPDES permit.

(f) Using any form of spray distribution when the instantaneous wind speed exceeds twenty miles per hour.

(g) To areas where a UIC class V injection well is present or within an area that could affect a UIC class V injection well.

(h) To areas where karst features, including unimproved sinkholes, are present or within an area that would contribute drainage that could affect the karst features.

(i) To areas where a professional soil scientist determines that any one of the following conditions exists below natural grade:

(i) Bedrock within twelve inches.

(ii) Fractured or karst bedrock within three feet.

(iii) Sand or gravel lenses within twelve inches.

(iv) Dense glacial till within twelve inches.

(v) Normal ground water elevation within twelve inches.

(j) When the ground is saturated at or near the surface, or any other condition that would result in runoff.

(k) To land where the land application contract has expired or is void.

(3) The director may allow the land application of treated sewage or liquid industrial waste to areas where the seasonal or perched ground water elevation exists during part of the year less than twelve inches below natural grade, provided the following:

(a) The land application only occurs when the normal ground water elevation, seasonal high ground water elevation, dense glacial till, sand or gravel lenses, or bedrock is at least twelve inches below natural grade.

(b) The storage volume requirements in table H-2 of this rule are met.

(c) Additional storage volume is provided for all of the treated sewage or liquid industrial waste that is generated, when land application is prohibited due to seasonal variations in the vertical separation distance.

(4) No person shall operate a land application system without an approved land application management plan.

(5) No person shall operate a discharging land application system without an approved NPDES permit and land application management plan.

(D) Land application systems: general requirements.

(1) A land application system shall be designed, operated and maintained in accordance with this chapter and all other applicable rules and laws. The director may deny any land application system permit application that does not contain the required information.

(2) Any land application management plan application shall be on forms specified by the director and shall include such additional information as the director deems necessary.

(3) No person shall allow the discharge of treated sewage or liquid industrial waste to waters of the state from a land application system without first obtaining an NPDES permit pursuant to Chapter 3745-33 of the Administrative Code.

(4) Any person proposing to use a land application system to treat sewage from two or more homes or to treat ten thousand gallons per day or greater of sewage or liquid industrial waste, and not proposing to contract with a public entity such as a county or municipality to operate the disposal system, shall submit the following information to demonstrate financial, legal and technical capability to own and operate a disposal system:

(a) Financial and personnel commitments that are needed to provide for effective management and operation of the land application system.

(b) Documentation of ownership accountability, which includes the legal authority to take the measures necessary for construction, operation, and maintenance of the land application system.

(c) Assurances that the applicant has committed to proper operation and management of the land application system, including assurance of compliance with certified operator requirements in accordance with Chapter 3745-7 of the Administrative Code.

(d) The organizational structure, credentials of management and operations personnel, and cooperative agreements or service contracts.

(e) Demonstration of the applicant's ability to address both customer and compliance issues, including violations of applicable portions of the Revised Code and the Administrative Code.

(f) A land application management plan in accordance with paragraph (E) of this rule that includes the following:

(i) A listing of external contacts and resources and a description of how they will be effectively utilized.

[Comment: External contracts and resources includes any maintenance or oversight that is outsourced.]

(ii) A financial plan describing the land application system revenues and cash flow for meeting the costs of construction and the costs of operation and maintenance for at least five full years from the date the applicant anticipates initiating operation. At a minimum, the financial plan shall include the following:

(a) Projected financial statements for each of the first five years of operation, including a balance sheet, an income statement and a statement of cash flow.

(b) A demonstration of ability to fund the cost of repairs, capital replacement, and compliance.

(E) Land application systems: land application management plan and NPDES permit requirements.

(1) A land application system shall be protective of public health and the environment.

(2) A land application system shall be operated in accordance with an approved land application management plan.

(3) Land application shall only occur at times identified in the approved land application management plan.

(4) Treated sewage or liquid industrial waste shall be land applied so as to minimize direct human contact, and the potential for creating aerosols and mist.

(5) Signs shall be installed at the entrance to each land application site, to inform the public that the land is used for land application of treated sewage or liquid industrial waste. At least one sign shall be posted at each field or site. Each sign shall include notification of the folllowing:

(a) All above ground sewage or liquid industrial waste distribution pipes contain "Non-potable Water that is Not Suitable for Human Consumption".

(b) If applicable, all nozzles distribute "Non-potable Water that is Not Suitable for Human Consumption."

(6) No treated sewage or liquid industrial waste shall be land applied within the emergency management zone of a public water system using surface water or within one thousand five hundred feet of any drinking water intake, whichever is greater unless the treated sewage or liquid industrial waste meets the water quality standards established for the public water supply use designation under Chapter 3745-1 of the Administrative Code.

(7) No person shall install a land application system after July 1, 2007 without first obtaining the following:

(a) For any land application system, a permit to install that includes a land application management plan. A land application management plan shall conform to the following:

(i) Be effective for five years, starting from the date it was approved by the director. A new land application management plan shall be submitted to Ohio EPA at least six months prior to expiration of any existing land application management plan. If a person submits a new land application management plan six months prior to expiration of the existing plan and Ohio EPA has not approved the new land application management plan prior to the expiration of the existing land application management plan, the existing land application management plan shall be effective until the new land application management plan is approved by the director. If a person does not submit a new land application management plan six months prior to expiration of the existing plan, the existing land application management plan will expire at the end of the five years.

(ii) Be in narrative form and shall include the following:

(a) Information about the operator of the land application system, including the following:

(i) The operator's classification necessary for operating the treatment works.

(ii) The number of hours per week that an operator will be working at the treatment works or land application area.

(iii) A description of the operator's experience in operating a land application system.

(b) A detailed description of the method or methods used for sewage or liquid industrial waste handling and storage.

(c) Characterization of the treated sewage or liquid industrial waste, including proposed effluent limits and corresponding minimum monitoring frequencies for the land application system.

[Comment: In accordance with paragraph (O)(3)(d) of this rule, effluent limits apply at the point the effluent leaves the treatment works, prior to storage, or prior to land application, if no storage is provided.]

(d) A detailed description of how operation and maintenance records will be maintained in accordance with this rule for the land application system.

(e) An equipment calibration and maintenance schedule.

(f) Written justification supporting the determination of land application rates, such as in inches per day. The land application rates shall ensure that no runoff occurs into surface waters of the state.

(g) Information on how any site specific management practices to prevent runoff will be maintained.

(h) The determination of appropriate weather conditions required for land application.

(i) A map that locates the present and known proposed occupied buildings, non-occupied buildings, developments and areas easily accessible to the public within three hundred feet of the land application area.

(j) A map that identifies the closest public sewerage system and its planning area, such as established pursuant to section 208 of the act, within one thousand feet of the land application area.

(k) A written contingency plan to protect human health and the environment at down gradient receptors shall be prepared. At a minimum, the contingency plan shall include the following response actions:

(i) For unauthorized releases to ground water from a storage facility or lagoon.

(ii) For events, including power outages or plant shutdowns, that result or could result in impacts to the following:

(A) Surface water.

(B) Drainage tiles that could affect surface water.

(C) Public or private water supplies.

(iii) For years with excessive wetness.

(iv) If storage capacity is exceeded.

(v) If the land application contract should become void.

(vi) Any other requirements, as required by the director to mitigate an unauthorized release.

(b) For any discharging land application system, a complete application for an NPDES permit in addition to paragraph (E)(7)(a) of this rule.

[Comment: All treatment works that discharge are subject to water quality standards rules, Chapter 3745-1 of the Administrative Code, and shall be processed according to the procedures in rule 3745-1-05 of the Administrative Code (antidegradation), Chapter 3745-2 of the Administrative Code, Chapter 3745-33 of the Administrative Code, Chapter 3745-42 of the Administrative Code and Chapter 3745-49 of the Administrative Code.]

(8) Requirements for land application systems installed prior to July 1, 2007. A land application system installed prior to July 1, 2007 shall be protective of public health and the environment. Where the director, or the director's authorized representative determines that an existing land application system is protective of public health and the environment, the director may waive any requirement in paragraph (C), (D), or paragraphs (F) to (N) of this rule in subsequent permits.

(F) Land application systems: permit to install application requirements. The following table summarizes the permit to install application requirements for a land application system and is not intended to be used in lieu of paragraphs (F)(1) to (F)(4) of this rule.

| Permit to install | Design flow (gallons per day) application requirements |

| Less than 10,000 | Greater than or equal to 10,000 |

| Land application rate | Land application rate |

| Less than or equal to 12 inches per acre per year | Greater than 12 inches per acre per year | Less than or equal to 12 inches per acre per year | Greater than 12 inches per acre per year |

| Rule paragraph | (F)(1) | (F)(2) | (F)(3) | (F)(4) |

| Engineering report | X | X | X | X |

| Site investigation report | X | X | X | X |

| Detailed plans and specifications | X | X | X | X |

| Land application contract | If applicable | If applicable | If applicable | If applicable |

| Treatment works operation and maintenance plan | If applicable | If applicable | If applicable | If applicable |

| Land application management plan | X | X | X | X |

| NPDES permit application | If applicable | If applicable | If applicable | If applicable |

| Hydraulic and nutrient balance for land application area | No | X | No | X |

| Ground water monitoring plan for land application area | No | Case by case | No | Case by case |

| Ground water monitoring plan for any storage facility | No | No | X | X |

| Ground water monitoring plan for any lagoon | X | X | X | X |

| Hydraulic balance for treatment works | Minimal information required | Minimal information required | X | X |

| Determine background phosphorus for land application area | No | X | X | X |

| Hydrogeological site investigation for land application area | No | Minimal information required | Minimal information required | X |

(1) The permit to install application for any land application system with a design flow less than ten thousand gallons per day and land application rates less than or equal to twelve inches per acre per year shall conform to the following:

(a) Include a hydraulic balance that does the following:

(i) Describes the assumptions and provides the calculations used to determine the initial and future design flows for the land application system.

(ii) Describes the assumptions and provides the calculations used to size the treatment works, including a storage facility, the land application area, the equipment and all appurtenances.

(b) Include a site investigation report for any lagoon, any storage facility or any land application area that is part of a land application system. The site investigation report shall conform to the following:

(i) Be prepared prior to any construction activities.

[Comment: If the construction activities include the construction of a golf course, Ohio EPA recommends that the site investigation be accomplished prior to the design of the golf course.]

(ii) Contain a soils and site evaluation for any lagoon, any storage facility or any land application area that is part of a land application system, in accordance with paragraph (N) of this rule.

(iii) Contain for any lagoon, any storage facility or any land application area that is part of a land application system, a detailed description of the existing and proposed surface and subsurface drainage ways within twenty feet of any lagoon or storage facility and within twenty feet of any land application area. This description shall include a map that is based on available records and any information obtained from site visits. The map shall locate the following:

(a) All surface drainage ways, including drainage swales, ditches, streams, rivers, natural or constructed wetlands, and ponds and lakes.

(b) All subsurface tiles and subsurface drains within two vertical feet below natural grade.

(iv) Contain for any lagoon, a hydrogeologic site investigation report. The hydrogeological site investigation report shall be developed in accordance with paragraph (M) of this rule.

(v) Contain for any lagoon, a ground water monitoring plan in accordance with paragraph (L) of this rule, if required by paragraph (L) of this rule.

(vi) Contain for any storage facility, in lieu of a hydrogeologic site investigation report, publicly available published hydrogeologic information including, but not limited to the following:

(a) Ground water resource maps, ground water pollution potential maps, surficial geology maps, and water well logs from the Ohio department of natural resources.

(b) United States department of agriculture soil surveys.

(c) United States geological survey studies.

(d) Other readily available sources that cover an area within two thousand feet from the boundaries of the site.

(e) The results of all onsite geotechnical studies conducted at the site to include all subsurface data gathered. If soil probes, soil pits or soil borings are required to characterize the site, they shall be done in accordance with paragraph (N) of this rule.

(c) In accordance with this chapter, include detailed engineering plans and specifications. In addition to the other requirements of this chapter, the detailed engineering plans shall also include a site plan that shall conform to the following:

(i) Be drawn to scale.

(ii) Show isolation distances in accordance with paragraphs (H) and (J) of this rule.

[Comment: Isolation distances. In the case of any reference to a building, the measurement shall be taken from the outside wall of the building. In the case of any reference to a treatment works or a component of the treatment works or a pump station, the measurement shall be taken from the closest point on the perimeter of the treatment works, the component of the treatment works, or the pump station. In the case of any reference to a lagoon or storage facility, the measurement shall be taken from the outer bank or the toe of the impoundment.]

(iii) Show any onsite treatment works, buildings, storage facilities, land application areas, and land application or distribution networks, and the application areas for each nozzle, center pivot system or point of distribution.

(iv) Provide the location of buildings and roads within one hundred feet beyond the perimeter of the land application system.

(v) Provide the location of any public drinking water supply intakes within one hundred feet beyond the perimeter of the land application system on the detailed plans.

(vi) Provide the location of any wells, including drinking water wells and UIC class V injection wells, within one hundred feet beyond the perimeter of the land application system.

(vii) Provide the location of drinking water source protection areas and inner management zones for public water systems using ground water and emergency management zones for public water systems using surface water within one hundred feet beyond the perimeter of the land application system.

(viii) Provide the location of the existing and proposed surface and subsurface drainage ways within twenty feet of any lagoon, any storage facility or any land application area.

(d) Include a land application contract for any land application system that does not maintain the isolation distances, in accordance with paragraphs (H) and (J) of this rule. For a land application system that serves more than one residence and where land application is the sole method of disposal, the director may require a land application contract for ninety-nine years.

(e) If applicable, include a treatment works operation and maintenance plan. If the permit to install is for a treatment works as part of the land application system, the operation and maintenance plan shall address the following:

(i) The operating procedures for each component of the treatment works.

(ii) The required sampling and monitoring procedures.

(iii) The maintenance schedule for each component of the treatment works and appurtenant structures.

(iv) A plan for maintenance of the storage facility liner system that includes, but is not limited to, a description of the steps to be taken to clean the sludge from the storage facility and the inspection and maintenance schedule for the liner to ensure tears, obvious flaws and ruptures are documented and corrected.

[Comment: The ultimate goal of the plan shall be to ensure the integrity of the liner system that will in turn protect the underlying ground water resources.]

(f) Include a land application management plan in accordance with paragraph (E) of this rule.

(2) A permit to install application for any land application system with a design flow less than ten thousand gallons per day and land application rates greater than twelve inches per acre per year, shall conform to the following:

(a) Meet all requirements in paragraph (F)(1) of this rule.

(b) Include a hydraulic and nutrient balance for the land application area, except as otherwise prescribed in this paragraph. A hydraulic and nutrient balance that supports the proposed size of land needed for land application shall be submitted with the permit to install. The hydraulic and nutrient balance shall demonstrate that the phosphorus and nitrogen loading rates will not adversely impact surface or ground waters. The application shall demonstrate the following:

(i) Nitrogen. If the total inorganic nitrogen limit of ten milligrams per liter (i.e., nitrogen option 1) will be met, then a nitrogen balance is not required. The concentration of nitrate-nitrogen in the ground water below land on which treated sewage or liquid industrial waste has been applied shall at all times be less than ten milligrams per liter. The Ohio State university extension bulletin number 860, "Reuse of Reclaimed Wastewater Through Irrigation", demonstrates an acceptable procedure for calculating the nitrogen nutrient and hydraulic balance. The director may accept alternate design criteria provided that the permit to install demonstrates to the satisfaction of the director that there will be no adverse impact to surface water or ground water as a result of the alternate design criteria.

(ii) Phosphorus. The soils shall be tested for phosphorus levels. Samples shall be representative of a land application site with one composite soil sample representing no more than twenty-five acres or one composite soil sample for each land application site, whichever is less. A sample depth of 8 inches shall be used unless justified otherwise in the plan. The Bray-Kurtz P1 extraction or Mehlich 3 extraction shall be used to determine the background level unless an alternative method is approved by the director.

Unless otherwise deemed acceptable by the director, the restriction of phosphorus application shall be based on the phosphorus index method, as developed by the natural resource conservation service in Ohio. For soils with soil phosphorus test results greater than one hundred fifty parts per million (three hundred pounds per acre) Bray-Kurtz P1 extraction or one hundred seventy parts per million (three hundred forty pounds per acre) Mehlich 3 extraction, the director shall not approve land application of treated sewage or liquid industrial waste unless the permit to install demonstrates to the director, using a phosphorus index, that there is a low relative risk of phosphorus movement to waters of the state at the land application site.

(c) Provide a ground water monitoring plan in accordance with paragraph (L) of this rule for any land application area.

(d) Include in the engineering report a characterization of the land application area that includes the following:

(i) The location of all class V injection wells, public water system wells, drinking water source protection areas and inner management zones for public water systems using ground water public water supply intakes, and private water wells, any part of which wells, areas or zones are within two thousand feet of any proposed storage facility site.

(ii) For any construction related activities, identification of all soil additions and soil amendments that may be made to the site that will substantially alter the permeability or infiltrative capacity of the soil.

(3) A permit to install application for any land application system with a design flow greater than or equal to ten thousand gallons per day and land application rates less than or equal to twelve inches per acre per year shall conform to the following:

(a) Meet all requirements in paragraph (F)(1) of this rule.

(b) Include, for any land application system where land application is the sole method of disposal, a land application contract for at least ninety-nine years, unless an alternative non-discharging option is available and included in the land application management plan.

(c) Include a ground water monitoring plan in accordance with paragraph (L) of this rule for any storage facility.

(d) Include in the engineering report for any treatment works, a hydraulic balance used to size the treatment works.

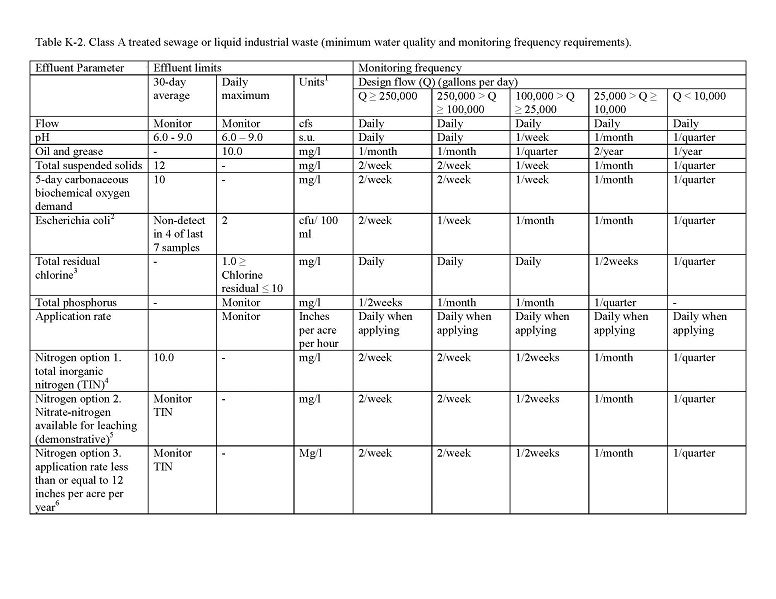

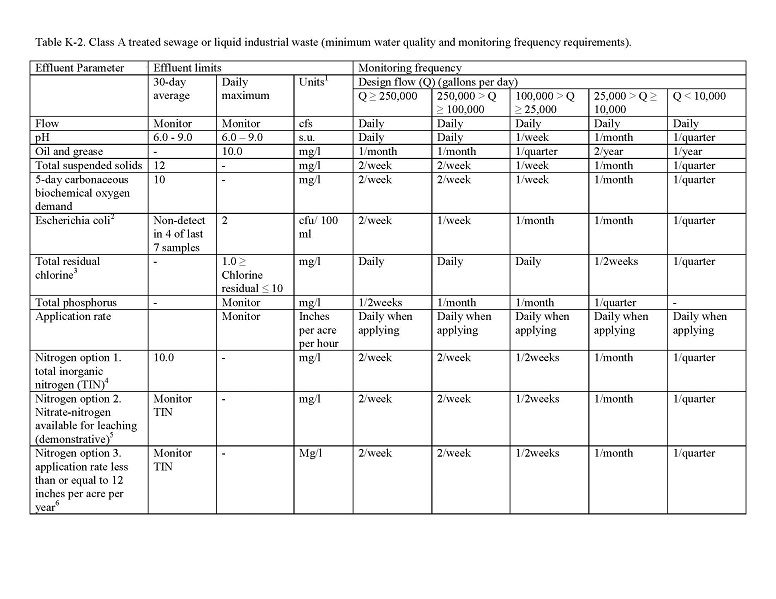

(e) Include in the engineering report for any treatment works not proposing to meet class A treated sewage or liquid industrial waste effluent limits in table K-2 of this rule, additional information, as deemed necessary by the director, regarding the sizing of the storage and land application area.

(f) Include as part of the site investigation report a characterization of the land application area that includes the following:

(i) The location of all class V injection wells, public water system wells, drinking water source protection areas and inner management zones for public water systems using ground water public water supply intakes, and private water wells, any part of which wells, areas or zones are within two thousand feet of any proposed storage facility site.

(ii) For any construction related activities, identification of all soil additions and soil amendments that may be made to the site that will substantially alter the permeability or infiltrative capacity of the soil.

(4) A permit to install application for any land application system with a design flow greater than ten thousand gallons per day and land application rates greater than twelve inches per acre per year shall conform to the following:

(a) Meet all requirements in paragraphs (F)(1) to (F)(3) of this rule.

(b) Include a ground water monitoring plan in accordance with paragraph (L) of this rule for any treatment works.

(c) Include a hydrogeologic site investigation in accordance with paragraph (M) of this rule for the land application area.

(d) Include, in the engineering report, a hydraulic balance used to size the storage facility.

(G) Land application systems: design requirements for a treatment works or sewerage system. Except where specific design criteria or methodologies are required by this rule, generally accepted design standards and methodologies shall be used to design the treatment works, including any treatment lagoon, or the sewerage system that is part of any land application system.

[Comment: One example of a set of generally accepted design standards and methodologies is "Great Lakes-Upper Mississippi River Board of State and Provincial Public Health and Environmental Managers - Recommended Standards for Wastewater Facilities, also known as Ten States Standards."]

(H) Land application systems: design requirements for storage facilities.

(1) A storage facility shall conform to the following:

(a) Maintain the isolation distance requirements listed in table H-1 of this rule. The director may reduce the isolation distance requirements if the storage facility contains class A treated sewage or liquid industrial waste.

[Comment: Isolation distances. In the case of any reference to a building, the measurement shall be taken from the outside wall of the building. In the case of any reference to a treatment works or a component of the treatment works or a pump station, the measurement shall be taken from the closest point on the perimeter of the treatment works, the component of the treatment works, or the pump station. In the case of any reference to a lagoon or storage facility, the measurement shall be taken from the outer bank or the toe of the impoundment.]

| Siting criteria | Minimum required isolation distance (feet) |

| Occupied building | Three hundred |

| Private potable water source not owned by the person land applying treated sewage or liquid industrial waste | Three hundred |

| Private potable water source owned by the person land applying treated sewage or liquid industrial waste | Fifty |

| UIC class V injection well | Three hundred |

| Property line | Fifty |

(b) For earthen impoundments, have inner and outer slopes no steeper than one foot vertical to three feet horizontal.

(2) Siting requirements for storage facilities.

[Comment: Information on the location of drinking water source protection areas, inner management zones, emergency management zones and public water wells and intakes can be obtained from the Ohio EPA division of drinking and ground water source water assessment and protection program at (614) 644-2752, by email at whp@epa.ohio.gov or on the internet at http://www.epa.ohio.gov/ ddagw/swap.aspx.]

(a) Storage facilities may not be located within drinking water source water protection area for a community, or non-transient non-community public water system using ground water unless:

(i) The proposed site is approved by the director.

(ii) Additional engineering controls to minimize the chance of liner failure are included.

(iii) A minimum of fifteen feet of low permeability material exists between the bottom of the liner and the top of the uppermost aquifer system.

(iv) A vertical separation distance of at least three feet is maintained between the bottom of the storage facility liner and bedrock.

(v) The storage facility is located outside the sanitary isolation radius of a public water system well, as determined in accordance with rule 3745-9-04 of the Administrative Code.

(vi) The storage facility is located outside of the inner management zone for a community water supply or non-transient, non-community public water system using ground water.

(vii) The storage facility is located outside a drinking water source protection area for a non-transient, non-community or transient, non-community public water system using ground water, the storage facility is located at least three hundred feet away from a water supply well for a non-transient, non-community or transient, non-community public water system, or the storage facility is located beyond the farthest distance ground water will travel to such systems in one year, whichever results in a greater distance from the well. The director may reduce this isolation distance requirement for storage facilities that contain highly treated and disinfected treated sewage or liquid industrial waste.

(b) Storage facilities may not be located within three hundred feet of a water supply well for a transient, non-community public water system. The director may reduce this isolation distance requirement for storage facilities that contain highly treated and disinfected treated sewage or liquid industrial waste.

(c) Storage facilities may not be located within the emergency management zone of a public water system using surface water or not within one thousand five hundred feet of the drinking water intake, whichever results in a greater distance from the intake.

(3) Storage volume requirements. A storage facility shall be designed with adequate storage capacity to prevent a discharge to surface waters, except as permitted by an NPDES permit. The minimum storage requirements in table H-2 of this rule shall be met. The director may require a larger storage volume to ensure that sufficient storage is provided to meet in stream water quality standards during exceptionally dry periods, or to ensure sufficient storage is provided to accommodate inspections or offline repairs.

| Type of land application system | Minimum storage volume requirement |

| Controlled discharge permitted by an NPDES permit and land application | Two weeks of storage volume |

| Continuous discharge permitted by an NPDES permit and land application | Evaluated on a case by case basis |

| Any other land application system | Four months of storage volume |

[Comment: A continuous discharge occurs when a discharge by a land application system is permitted to surface waters year-round.]

(a) The storage volume shall be calculated using the disposal system design flow and shall consider all hydraulic inputs and outputs, including the following:

(i) The number of storage days required.

(ii) Whether or not there will be a controlled discharge in addition to land application.

(iii) The size of the land application area.

(iv) Site specific rainfall and evaporation data.

(v) The potential for solids accumulation.

(b) A smaller storage volume or no storage volume may be approved for a disposal system that includes a continuous discharge permitted under an NPDES permit.

[Comment: The Ohio State university extension bulletin number 860, "Reuse of Reclaimed Wastewater Through Irrigation", demonstrates an acceptable procedure for calculating the amount of storage volume necessary for non-discharging land application systems. The director may accept alternate design criteria, provided that the permit to install demonstrates to the satisfaction of the director that there will be no adverse impact to surface water or ground water, as a result of the alternate design criteria.]

(4) Freeboard requirements for storage facilities: the freeboard requirements in table H-3 of this rule shall be met. Storage facilities must be equipped with a depth marker which clearly indicates the minimum freeboard level.

| Design parameter | Minimum freeboard requirement for storage facility |

| Design flow less than one thousand gallons per day | Two feet |

| Volume of storage facility less than ten thousand gallons | Two feet |

| Concrete impoundment | Two feet |

| Earthen or partially earthen impoundment that holds more than ten thousand gallons | Three feet |

(5) Liner requirements for storage facilities. Except as provided in paragraphs (H)(16) and (H)(17) of this rule, the storage facility shall have a recompacted clay liner designed in accordance the following unless otherwise specified in the detailed engineering plans approved by the director:

(6) No soil material used in the liner shall be placed or recompacted during weather conditions, such as freezing temperatures or rain, that would interfere with adequate compaction or control of moisture content.

(7) Soil material used in the liner shall be placed in six inch to eight inch loose lifts at a moisture content between zero per cent and four per cent above optimum moisture content as determined by standard laboratory proctor.

(8) Soil material used in the liner shall be recompacted by using standard engineering compaction methods and recompacted to a minimum compaction rate of ninety-five per cent of standard dry density as determined by ASTM D698 or greater as required to achieve 1 x 10-7 centimeters per second maximum permeability. The most representative moisture-density curve shall be used to determine compaction rates.

(9) Compacted soil material used in the liner shall be tested for density and moisture content at a rate of one test per lift, with a minimum of one test for any day that soil material is compacted.

(10) When a density or moisture content test is not conducted in compliance with the approved detailed engineering plans or the terms and conditions of the permit to install, each lift shall be scarified and the moisture content adjusted and the soils recompacted for the area that extends from the location of the failed test to one-half the distance to the location of the nearest passed test, in all directions. The recompacted area shall then be retested for compliance.

(11) The results of density and moisture content testing shall be submitted to Ohio EPA.

(12) Soils used for the liner shall have from fifteen to thirty per cent clay content and shall be classified as CL or SC by the unified classification system (ASTM designation D2487). The remaining portion of the liner material should have a wide range of soil particles in the silt, fine sand and coarse sand range.

(13) When the classification of the proposed liner material can not be determined in accordance with the unified classification system, hydraulic conductivity tests shall be performed on the proposed lining material to confirm its classification and ensure the proposed liner will be in accordance with paragraph (H)(5) of this rule.

(14) There shall be a minimum of three feet of fine-grained soil over fractured rock outcrops or other highly permeable material, which may include the recompacted liner.

(15) The thickness of the recompacted clay liner shall be in accordance with table H-4 of this rule. Separation distance is:

(a) For any storage facility not located within a drinking water source water protection area, the vertical distance between the top of the storage facility liner and the top of the uppermost aquifer system or top of the first continuous significant zone of saturation underlying the storage facility, whichever is encountered first.

(b) For any storage facility located within a drinking water source water protection area, the vertical distance between the bottom of the storage facility liner and the top of the uppermost aquifer system or top of the first continuous significant zone of saturation underlying the storage facility, whichever is encountered first.

| Available vertical separation distance | Required thickness of recompacted clay liner |

| Three feet or more, but less than five feet | Twenty-four inches |

| Five feet or more, but less than ten feet | Eighteen inches |

| Ten feet or more | Twelve inches |

(16) If a synthetic liner is used in lieu of a recompacted clay liner, the liner shall conform to the following:

(a) Include, at a minimum, six inches of properly prepared subbase placed underneath the synthetic liner.

(b) Unless otherwise specified in the detailed engineering plans approved by the director, have a maximum permeability of 1 x 10-7 centimeters per second.

(c) Be designed based on considerations for potential freeze and thaw damage and potential exposure to ultraviolet rays.

(17) If the storage facility is constructed of reinforced concrete, the concrete shall be, at a minimum, five inches thick and include non-metallic water stops for all joints.

(I) Land application systems: design criteria for land application distribution systems.

(1) Spray distribution system. The design of any land application spray distribution system shall conform to the following:

(a) Provide for uniform distribution of the treated sewage or liquid industrial waste. Where a land application area consists of various soils groups do either of the following:

(i) Utilize different distribution zones, where the application rate varies per zone based on the site specific soils.

(ii) Determine an overall distribution rate by calculating a weighted average based on the site specific soils.

(b) Consider the size of suspended solids retained in the effluent when sizing the sprinkler or other distribution device. The diameter of the sprinkler nozzle used as part of the land application system shall be at least three times the size of any suspended solids in the treated sewage or liquid industrial waste being sprayed.

[Comment: Depending on the type of treatment works, the director may require additional screening or filtration to prevent spray nozzle clogging.]

(c) Consider the existence of surface and subsurface drainage ways and their potential to convey effluent to waters of the state.

(2) If soil probes, soil pits or soil borings are required to characterize the site, the soil probes, soil pits or soil borings shall be done in accordance with paragraph (N) of this rule.

(3) The director may consider a land application distribution system other than a spray distribution system, provided the following:

(a) The permit to install application demonstrates to the satisfaction of the director that there will be no adverse impact to surface water, ground water or human health as a result of the distribution system.

(b) The permit to install application is in accordance with this chapter and all other applicable rules and laws.

(c) The applicant demonstrates to the director that the design of the distribution system is based on sound engineering principles and standards.

(J) Land application systems: isolation distance requirements for land application areas.

(1) Except at times identified in the approved land application management plan provided in paragraphs (J)(5) to (J)(7) of this rule, the location of the land application area shall maintain the minimum isolation distances in table J-1 of this rule. The director may reduce the isolation distance requirements where class A treated sewage or liquid industrial waste is land applied. The director may increase isolation distance requirements to protect public health or the environment.

| Siting criteria | Minimum required isolation distance (feet) |

| Private potable water source not owned by the person land applying treated sewage or liquid industrial waste | Three hundred |

| Private potable water source owned by the person land applying treated sewage or liquid industrial waste | Fifty |

| UIC class V injection well | Three hundred |

| Sinkhole or karst feature | Three hundred |

| Property line | Fifty |

| Human crops that may be eaten raw | Fifty |

(2) In addition to the requirements of paragraphs (C) and (J)(1) of this rule, no person shall land apply class A treated sewage or liquid industrial waste as follows:

(a) Except at Ohio EPA approved unrestricted or Ohio EPA approved restricted access sites.

(b) Within fifty feet from an occupied building.

(c) Within the sanitary isolation radius for a public water system well, as determined in accordance with rule 3745-9-04 of the Administrative Code.

(d) Within the inner management zone of a source water protection area (one-year time-of-travel area) for a community or non-transient, non-community public water system using ground water or within three hundred feet of any public water system well.

(e) Within drinking water source protection area for a community or non-transient, non-community public water system using ground water determined to be highly susceptible to contamination unless additional engineering controls are installed sufficient to protect the ground water and ground water monitoring is performed in accordance with paragraph (L) of this rule, between the land application system and the public water system well.

(3) In addition to paragraphs (C), (J)(1), and (J)(2)(c) to (J)(2)(e) of this rule, no person shall land apply class B treated sewage or liquid industrial waste as follows:

(a) Except at Ohio EPA approved restricted access sites.

(b) At any site that contains sand and gravel as the predominant natural material within five vertical feet of natural grade.

(c) Within two hundred feet from an occupied building.

(d) Within fifty feet of developed springs, karsts, sinkholes, drainage ways, subsurface tiles with surface openings, surface water bodies, and road right-of-ways.

(e) On sodded fields and forested areas with slopes greater than twelve per cent unless measures able to control runoff approved by the director, such as berms, collection ditches or check dams, are installed.

(f) On fields with slopes greater than eight per cent unless the detailed engineering plans and specifications required by paragraph (F) of this rule include runoff control measures that demonstrate to the director runoff will not impact surface waters of the state.

(4) In addition to paragraphs (C), (J)(1), (J)(2)(c) to (J)(2)(e), and (J)(3)(b) to (J)(3)(f) of this rule, no person shall land apply class C treated sewage or liquid industrial waste except at Ohio EPA approved sites.

(5) The siting criteria and the isolation distance requirements of this paragraph shall not apply to occupied buildings if the person who will land apply treated sewage or liquid industrial waste obtains a land application contract from each owner of a neighboring occupied building located within the siting distances set forth in this rule and includes a copy of the land application contract with the permit to install application. The land application contract shall state that:

(a) The owner of the occupied building is aware of the proposed land application.

(b) The owner of the occupied building has no objection to the land application at a location not otherwise allowed by the isolation distance requirements and siting criteria in this rule.

(c) The land application occurs between dusk and dawn and the land application system utilizes low head sprinklers or an equivalent low-exposure distribution method.

[Comment: Night time or early morning land application usually reduces the risk of people coming into direct contact with the treated sewage or liquid industrial waste. Strict night time application is sometimes impractical and daytime application helps to reduce spills and over-application that might result from not being able to see the land application take place.]

(6) The director may reduce the isolation distance requirements to a property line if a land application contract from each property owner within the fifty-foot isolation distance is submitted as part of the permit to install application and treated sewage or liquid industrial waste is applied from dusk until dawn with low head sprinklers, or with an equivalent low-exposure distribution method. The land application contract shall state that these property owners are aware of, and have no objection to, the proposed land application of treated sewage or liquid industrial waste within fifty feet of their property lines.

(7) If class A treated sewage or liquid industrial waste requirements for effluent limits and monitoring requirements in table K-2 of this rule are met, the director may reduce the isolation distance restrictions established in this rule provided the applicant can demonstrate to the director that the potential for negative impacts to human health or waters of the state does not exist.

(K) Land application systems: treatment requirements, effluent water quality and monitoring requirements.

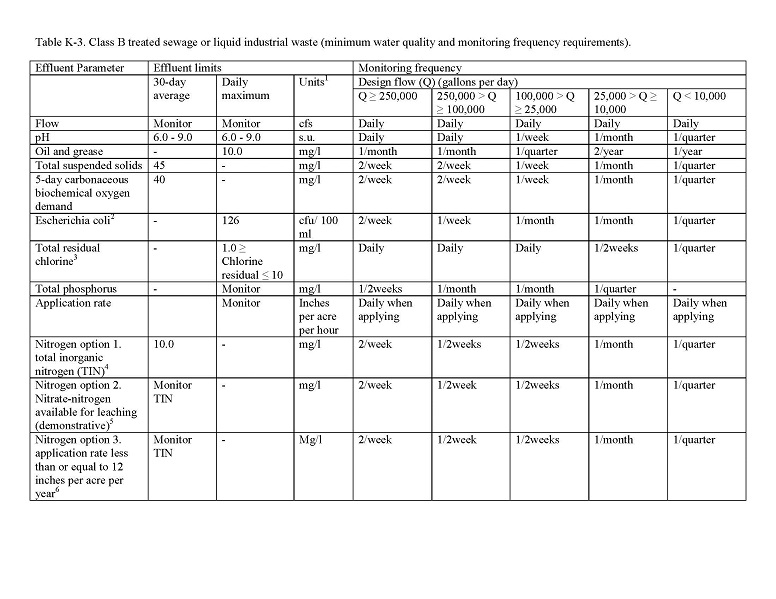

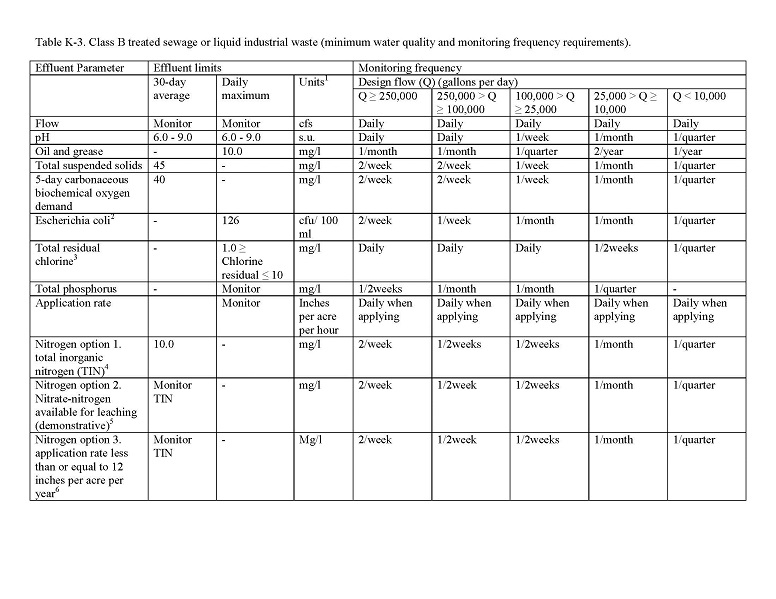

(1) A land application system shall be designed in accordance with table K-1 of this rule and shall have a land application management plan that contains effluent limits, which are developed and monitored in accordance with table K-1 of this rule. The director may require sampling and monitoring of pollutants not listed in tables K-2 to K-5 of this rule, to protect public health or the environment. The director may require treated sewage or liquid industrial waste that will be land applied to a golf course or athletic field to meet class A treated sewage or liquid industrial waste requirements in accordance with table K-2 of this rule.

(2) In addition to paragraph (K)(1) of this rule, any land application system that will discharge to waters of the state shall have an approved NPDES permit that contains, where applicable, internal and final effluent limits as follows:

(a) The internal limits shall be developed and monitored in accordance with table K-1 of this rule and be applied at the point the effluent leaves the treatment works, prior to storage, or prior to land application if no storage is provided.

(b) The final effluent limits shall be developed in accordance with best available demonstrated control technology criteria, as set forth in table 5-1 of rule 3745-1-05 of the Administrative Code or water quality based effluent limits in accordance with Chapter 3745-1 of the Administrative Code, whichever is more stringent.

| Design flow for land application system (gallons per day) | Minimum sewage or liquid industrial waste treatment class | Minimum effluent limits and minimum monitoring frequency requirements |

| Less than ten thousand | Class C | Table K-4 |

| Greater than or equal to ten thousand | Class B | Table K-3 and table K-5 |

(3) The director may waive any requirement of paragraph (K)(1) of this rule, provided that the person requesting the waiver has demonstrated to the satisfaction of the director that the waiver is unlikely to adversely affect the public health or safety or the environment.

(4) In order to meet the effluent limits set forth in table K-3 or K-4 of this rule, disinfection prior to land application may be required.

1cfs = cubic feet per second; s.u. = standard units; mg/l = milligrams per liter; cfu/100 ml = colony forming units per 100 milliliters.

2All wastewater treatment works shall use E. coli as the indicator organism unless fecal coliform is specified by their existing NPDES permit.

3Chlorine residual only necessary for those disposal systems that use chlorine for disinfection.

4The 10.0 mg/l effluent limit is measured at the discharge outfall of the wastewater treatment plant.

5The 10.0 mg/l effluent limit met at point treated sewage or liquid industrial waste reaches the bottom of the root zone based on approved nutrient balance.

6Inches per acre per year represents the application rate over the time period of a single calendar year (i.e., January 1 to December 31).

1cfs = cubic feet per second; s.u. = standard units; mg/l = milligrams per liter; cfu/100 ml = colony forming units per 100 milliliters.

2All wastewater treatment works shall use E. coli as the indicator organism unless fecal coliform is specified by their existing NPDES permit.

3Chlorine residual only necessary for those disposal systems that use chlorine for disinfection.

4The 10.0 mg/l effluent limit is measured at the discharge outfall of the wastewater treatment plant.

5The 10.0 mg/l effluent limit met at point treated sewage or liquid industrial waste reaches the bottom of the root zone based on approved nutrient balance.

6Inches per acre per year represents the application rate over the time period of a single calendar year (i.e., January 1 to December 31).

| Effluent parameter | Effluent limits | Monitoring frequency |

| 30-day average | Daily maximum | Units2 | Design flow (Q) 10,000 |

| Flow | Monitor | Monitor | cfs | Daily |

| pH | 6.0 - 9.0 | 6.0 - 9.0 | s.u. | 1/quarter |

| Oil and grease | - | 10.0 | mg/l | 1/year |

| Total suspended solids | 45 | - | mg/l | 1/quarter |

| 5-day carbonaceous biochemical oxygen demand | 40 | - | mg/l | 1/quarter |

| Escherichia coli3,4 | - | 298 | cfu/100 ml | 1/quarter |

| Total residual chlorine3 | - | Chlorine residual greater than or equal to 0.1 but less than or equal to 10 | mg/l | 1/quarter |

| Application rate | - | Monitor | inches per acre per hour | Daily when applying |

| Nitrogen option 1. total inorganic nitrogen (TIN)5 | 10.0 | - | mg/l | 1/quarter |

| Nitrogen option 2. nitrate-nitrogen available for leaching (demonstrative)6 | Monitor TIN | - | mg/l | 1/quarter |

| Nitrogen option 3. application rate less than or equal to 12 inches per acre per year7 | Monitor TIN | - | mg/l | 1/quarter |

1Class C treated sewage or liquid industrial waste shall only be land applied at times set forth in an approved land application management plan (i.e., times of the day that will minimize human exposure to the application of the treated sewage or liquid industrial waste, such as early morning between 4:00 a.m. and 9:00 a.m.).

2cfs = cubic feet per second; s.u. = standard units; mg/l = milligrams per liter; cfu/100 ml = colony forming units per one hundred milliliters.

3Chlorine residual only necessary for those disposal systems that use chlorine for disinfection. Effluent disinfection is not directly required; however, the entity is required to meet all applicable discharge permit limits. If disinfection facilities exist, they need to be maintained in an operable condition. Any design of wastewater treatment works should provide for the capability to install disinfection if required at a future time. Disinfection may be required if bacteriological studies or emergency conditions indicate the need.

4All wastewater treatment works shall use E. coli as the indicator organism unless fecal coliform is specified by their existing NPDES permit.

5The 10.0 mg/l effluent limit is measured at the discharge outfall of the wastewater treatment plant.

6The 10.0 mg/l effluent limit met at point treated sewage or liquid industrial waste reaches the bottom of the root zone based on approved nutrient balance.

7Calculations for the demonstrative nitrogen balance (i.e., nitrate-nitrogen available for leaching) are not required to be submitted if the application rate is designed to be less than or equal to twelve inches per acre per year.

| Effluent parameter | Effluent limits | Monitoring frequency based on design flow (Q) in gallons per day |

| Maximum concentration | Units2 | Q greater than or equal to 100,000 | 100,000 Q 10,0003 |

| Aluminum | 5.0 | mg/l | 1/year | 1/5 years |

| Arsenic | 0.10 | mg/l | 1/year | 1/5 years |

| Beryllium | 0.10 | mg/l | 1/year | 1/5 years |

| Boron | 0.75 | mg/l | 1/year | 1/5 years |

| Cadmium | 0.01 | mg/l | 1/year | 1/5 years |

| Chromium | 0.1 | mg/l | 1/year | 1/5 years |

| Cobalt | 0.05 | mg/l | 1/year | 1/5 years |

| Copper | 0.2 | mg/l | 1/year | 1/5 years |

| Fluoride | 1.0 | mg/l | 1/year | 1/5 years |

| Iron | 5.0 | mg/l | 1/year | 1/5 years |

| Lead | 1.5 | mg/l | 1/year | 1/5 years |

| Lithium | 2.5 | mg/l | 1/year | 1/5 years |

| Manganese | 0.2 | mg/l | 1/year | 1/5 years |

| Molybdenum | 0.01 | mg/l | 1/year | 1/5 years |

| Nickel | 0.2 | mg/l | 1/year | 1/5 years |

| Selenium | 0.02 | mg/l | 1/year | 1/5 years |

| Vanadium | 0.1 | mg/l | 1/year | 1/5 years |

| Zinc | 2.0 | mg/l | 1/year | 1/5 years |

1To protect public health and the environment, the director may require monitoring for mercury.

2mg/l = milligrams per liter.

3Shall be submitted as part of the initial and renewal application.

(L) Land application systems: ground water monitoring program requirements for land application areas, lagoons and storage facilities.

(1) Ground water monitoring program: exemptions for land application areas. A ground water monitoring program is not required for the following:

(a) A land application area where class A treated sewage or liquid industrial waste is land applied, unless the chief of the division of drinking and ground waters of Ohio EPA or the chief's authorized representative determines that ground water could be contaminated by class A treated sewage or liquid industrial waste.

(b) A land application area where less than or equal to twelve inches of class B treated sewage or liquid industrial waste is land applied per acre per year.

(c) A land application area when less than or equal to twelve inches of class C treated sewage or liquid industrial waste is land applied per acre per year.

(2) Ground water monitoring program: exemptions for storage facilities.

(a) A ground water monitoring program is not required for a storage facility when the treatment works that is part of a land application system has a design hydraulic capacity of less than one thousand gallons per day.

(b) A ground water monitoring program is not required for a storage facility when the treatment works that is part of a land application system has a design hydraulic capacity of less than ten thousand gallons per day, and the storage facility conforms to the following:

(i) Includes a liner that is installed for the storage facility that meets the requirements of paragraph (H) of this rule.

(ii) Contains only class A treated sewage or liquid industrial waste.

(c) A ground water monitoring program is not required for a storage facility when there is more than fifteen feet of low permeability material between the bottom of the storage facility liner and the top of the first continuous significant zone of saturation, and the storage facility conforms to either of the following:

(i) Is more than one thousand five hundred feet from the boundaries from public water supply intake.

(ii) Is not over an aquifer that yields or is capable of yielding more than one hundred gallons of water per minute.

(3) Ground water monitoring program: applicability for land application areas. The director may require a ground water monitoring program for any of the following:

(a) Any land application area where more than twelve inches per year of class B treated sewage or liquid industrial waste is land applied and there is less than five feet between the surface area in the application area and the top of the first continuous significant zone of saturation.

(b) Any land application area where more than twelve inches per year of class C treated sewage or liquid industrial waste is land applied and there is less than five feet between the surface area in the application area and the top of the first continuous significant zone of saturation.

(c) Any land application area where the distribution system is not a spray distribution system.

(d) Any land application area where the seasonal or perched ground water elevation can occur less than twelve inches below natural grade.

(4) General requirements for the ground water monitoring program. Except as provided in paragraphs (L)(1) and (L)(2) of this rule, or unless waived by the director, ground water monitoring shall be provided for any lagoon, any storage facility, or any land application area that is a part of a land application system.

(a) No land application system shall be operated without an approved ground water monitoring program.

(b) A copy of the written ground water monitoring program plan and all analytical results, including quality assurance information, shall be kept and shall be made available for inspection by Ohio EPA staff upon request.

(c) A ground water monitoring program that is capable of determining the impact of the land application system on the first continuous significant zone of saturation underlying the land application system shall be conducted. The ground water monitoring program shall conform to the following:

(i) Continue as long as required by the director.

(ii) Include sampling and analysis methods and procedures capable of yielding a sample representative of ground water quality in the zone monitored.

(iii) Provide at least three ground water monitoring wells for any storage facility, lagoon or land application area. The monitoring well layout shall include the following:

(a) One monitoring well up-gradient of the storage facility, lagoon or land application area.

(b) Two monitoring wells down-gradient of the storage facility, lagoon or land application area into the first continuous significant zone of saturation underlying the storage facility, lagoon or land application area.

(d) All monitoring wells shall conform to the following:

(i) Be installed and maintained in such a manner that will allow a ground water sample to be obtained from the well that is representative of ground water quality in the ground water unit into which the well is screened. All monitoring well locations shall be surveyed and all well construction and maintenance documentation shall be kept at the site of the storage facility and be available for inspection by Ohio EPA staff upon request.

(ii) Be sampled semi-annually for the parameters listed in tables L-1 and L-2 of this rule. The parameters listed in tables L-1 and L-2 of this rule may be modified or expanded by the director based on site-specific waste characterization, to protect public health and the environment. The director may require a sampling frequency less frequent than semi-annually, provided the owner or operator has demonstrated to the director, based on at least three consecutive years of sampling results, that human health and the environment will be protected.

| pH |

| Specific conductivity |

| Temperature |

| Turbidity |

| Ammonia |

| E. coli or total coliform |

| Nitrate-nitrogen plus nitrite-nitrogen |

| Chloride |

[Comment: Ammonia, E. coli, total coliform, nitrate-nitrogen plus nitrite-nitrogen and chloride are parameters that can indicate ground water contamination.]

(e) All field forms, laboratory data to include quality assurance or quality control information, and other pertinent information related to the semiannual sampling event shall be kept and made available for inspection by Ohio EPA staff upon request.

(f) Within seventy-five days of sampling, a letter that includes a table containing the summarized analytical results for each monitoring well for each semi-annual sampling event shall be forwarded to the director, or to the director's duly authorized representative.

(g) The following results shall be forwarded to the director, or to the director's duly authorized representative, within fifteen days of receipt:

(i) Nitrate-nitrogen plus nitrite-nitrogen or ammonia concentrations that are greater than five parts per million.

(ii) Chloride concentrations that are greater than one hundred twenty-five parts per million.

(iii) Total coliform or E. coli bacteria that is detected

(iv) Additional parameters at concentrations as required by the director based on site-specific waste characterization.

(h) If the director determines, based on the ground water monitoring results, that a potential for significant adverse impact to the environment or public health is posed or if there is an impact to ground water, all land application operations shall cease until the director provides notification in writing that operations may resume. The director may require the following:

(i) A more detailed ground water impact evaluation.

(ii) Additional monitoring wells at or near the property boundary between the contaminant plume and the down gradient receptors (such as public or private drinking water wells, springs and surface water sites used for drinking water) to be installed to evaluate the rate, extent and concentration of the contaminant plume.

(i) Any monitoring well or boring drilled at the proposed or permitted storage facility, that is no longer needed, shall be abandoned in accordance with the requirements of rule 3745-9-10 of the Administrative Code and any other applicable requirements.

[Comment: For additional information concerning hydrogeologic site investigations and ground water monitoring procedures, consult the Ohio EPA division of drinking and ground waters "Technical Guidance Manual for Hydrogeologic Investigations and Ground Water Monitoring".]

(M) Land application systems: hydrogeologic site investigation requirements. When a hydrogeologic site investigation is required by paragraph (F) of this rule, a hydrogeologic site investigation report shall be submitted as part of the permit to install application that, at a minimum conforms to the following:

(1) Is presented in narrative form.

(2) Contains sufficient hydrogeologic information to allow the director to do the following:

(a) Identify and characterize the hydrogeology of the first continuous significant zone of saturation under the land application system and all geologic strata that exist above that zone.

(b) Sufficiently characterize the site geology to allow for the evaluation of the proposed design of the land application system and to ensure that it will comply with the requirements of this chapter and Chapter 6111. of the Revised Code.

(3) Contains a description, based on publicly available information, of the hydrogeology within two thousand feet of the perimeter of the proposed land application system. This description shall do the following:

(a) Identify all aquifer systems used as water supplies.

(b) Include all well logs of public and private water supply wells.

(c) Identify the average regional yield of the uppermost aquifer system underlying the site.

(d) Describe the direction of ground water flow in the aquifer systems used as water supply sources.

(e) Identify recharge and discharge areas for any of the aquifer systems used as water supply sources.

(f) Identify on a map any of the following:

(i) Public water system wells within two thousand feet of the perimeter of the land application system.

(ii) Drinking water source protection areas and inner management zones for public water systems using ground water.

(iii) Emergency management zones that extend to or past the nearest land application system boundary.

(g) Describe the regional stratigraphy including any regional stratigraphic or structural features, such as the bedrock surface, bedrock dip or joint structures, that may influence the ground water flow system.

(h) Describe the regional geomorphology, including the location of surface water bodies, flood plains, etc.

(i) Describe any topographic features that may influence the ground water flow system and structural geology.

(4) Describe in detail and analyze the geology and hydrogeology under the proposed land application system. This description shall be based on data collected using appropriate subsurface investigatory methods such as borings, monitoring wells, tensiometers, geophysical surveys, soil surveys, cone penetrometers, piezometers and test pits. The description shall, at a minimum do the following:

(a) Describe the consolidated and unconsolidated deposits forming stratigraphic units from natural grade down to the base of the first continuous significant zone of saturation underlying the land application system including the following characteristics:

(i) For unconsolidated stratigraphic units, the textural classification using the unified soil classification system (USCS).

(ii) For consolidated stratigraphic units, if necessary, the rock types, such as limestone, dolomite, coal, shale, siltstone and sandstone.

(iii) Color, moisture content, stratigraphic features such as layering, interbedding or weathering, fracturing, jointing and other types of secondary porosity and any other visible accessory minerals such as pyrite, calcite or gypsum.

(iv) Atterberg limits.

(v) Grain size distribution (sieve and hydrometer curves for representative samples of each group of borings of similar soil composition).

(vi) Hydraulic conductivity.

(vii) Thickness.

(viii) Lateral extent.

(ix) Depth and elevation.

(b) Describe the geomorphology at the proposed land application system, including surface water bodies and topographic features, that may influence the flow of ground water in the first continuous significant zone of saturation or any overlying significant zones of saturation including the identification and characterization of recharge and discharge areas within the boundaries of the proposed land application system. This description shall include identification of any sources of seeps, springs, streams and other surface water features.

(c) Describe variations in texture, saturation, stratigraphy, structure or mineralogy exhibited by each stratigraphic unit that could influence the ground water flow or quality in the first continuous significant zone of saturation or any overlying significant zones of saturation.

(d) Describe the first continuous signification zone of saturation under the land application system, including the depth to, and lateral and vertical extent of, the first continuous significant zone of saturation under the land application area. This description shall, at a minimum do the following:

(i) Describe in both a narrative and on a map, the ground water flow system, including rate of flow, and direction of flow in the first continuous significant zone of saturation to extend underlying the land application system.

(ii) Identify and characterize recharge and discharge areas within the boundaries of the proposed land application system, including any connections of ground water with seeps, springs, streams and other surface water features.

(e) Describe in detail the following:

(i) The drilling and soil sampling methods used in characterizing the soil and hydrogeologic properties of any unconsolidated and consolidated rock material underlying the proposed land application system.

(ii) The analytical procedures and methodology used to characterize the soil and rock materials obtained from test pits and borings.

(iii) The methodology, equipment and procedures used to define the first continuous significant zone of saturation underlying the land application system, including:

(a) Well and piezometer construction specifications.

(b) Water level measurement procedures.

(iv) The methodology, equipment and procedures used to determine the ground water quality (if determined) in any significant zone of saturation including the requirements specified in paragraph (J)(4) of this rule.

(f) Submit all boring logs, test pit logs, ground water quality data and soil analytical data and any other data generated while preparing this report.

(N) Soil and site evaluation requirements. For every land application system, a soil and site evaluation shall be done in accordance with this paragraph and shall conform to the following:

(1) Be submitted on forms approved by the director to the appropriate Ohio EPA district office.

(2) Be submitted with a permit to install application.

(3) Include a site specific soil map which locates, as necessary, any soil probes, any soil delineations, any soil pits or soil borings. In addition to the information in the general soil survey, the location of any soil delineations and the location and number of soil probes, pits or borings necessary to describe the soil conditions shall be determined by a professional soil scientist for the land application site, the lagoon site or the storage facility site. The soil delineations, soil probes, soil pits or soil borings shall conform to the following:

(a) Be performed or evaluated by a professional soil scientist.

[Comment: For soil borings deeper than fifteen feet, a professional with the appropriate knowledge and experience, such as a geologist or hydrogeologist, should also be consulted.]

(b) Be taken prior to any construction activities.

(c) When the proposed land application area is a golf course, be taken prior to the construction of any tee boxes, fairways and greens.

(d) For any land application area, be done to a minimum depth of thirty inches below natural grade. To protect public health or the environment, the director may require deeper soil probes, soil pits or soil borings. In areas where glacial till and fractured bedrock substratum soils are in close proximity, the soil investigation shall be done to a depth of at least fifty inches or until bedrock is encountered.

(e) For any storage facility or lagoon, be done to a minimum depth of fifteen feet below the proposed bottom of the recompacted clay liner.

[Comment: The county soil maps are at a scale for larger systems and for land use planning purposes. A more detailed map should be developed for land application systems so that all the included soils can be delineated, characterized, and avoided, if necessary. The Ohio state university extension bulletin number 905, "Soil and Site Evaluation for Onsite Wastewater Treatment", demonstrates an acceptable procedure for developing soil maps.]

(4) Based on the information in the general soil survey, published loading rate tables, and the data from any soil borings, identify the permeability and thickness of the following:

(a) The most permeable layer of the soil mantle at each soil probe, soil pit or soil boring location.

(b) The least permeable layer of the soil mantle at each soil probe, soil pit or soil boring location.

(5) Identify the vertical separation distance between the natural grade and all of the following conditions:

(a) Bedrock.

(b) Sand and gravel lenses.

(c) Dense glacial till.

(d) Ground water, including any seasonal high ground water or perched water table.

(6) Discuss the site topography, including the following:

(a) The site slope.

(b) The site vegetative cover.

(c) Any drainage ways and waterways within, below or bordering the land application system.

(d) Any impervious surfaces.

(O) Record keeping, reporting requirements, compliance, enforcement, and oversight.

(1) Record keeping.

(a) Records shall be maintained on forms provided by or approved by the director.

(b) Upon request by the director or the director's authorized representative, any person shall make available, within a reasonable time for inspection and copying, all records pertaining to the land application system, including the following:

(i) Pollutant sampling records.

(ii) Inflow and outflow monitoring records.

(iii) Storage impoundment monitoring records for freeboard and the number of days of remaining storage.

(c) Any person who owns a land application system shall maintain all sampling and monitoring records at the treatment works for at least five years. These records shall be made available to Ohio EPA, upon request.

(2) Reporting requirements.

(a) The director shall be notified in writing within seven days of any person discovering noncompliance with a land application management plan or an NPDES permit.

(b) The director shall be notified at least six months prior to the expiration date of a land application contract.

(3) Compliance, enforcement and oversight.

(a) The director may deny any land application management plan application not in compliance with this chapter and require the submittal of a new land application management plan application, including all applicable fees, to be submitted to Ohio EPA within thirty days.

(b) The director may revoke approval of any land application management plan, where the land application system is de-commissioned or a proposed land application system is never built.

(c) The director may revoke approval of any land application management plan not in compliance with this chapter.

(d) A land application system shall maintain compliance with effluent limits in the land application management plan or NPDES permit at the point the effluent leaves the treatment works, prior to storage, or prior to land application, if no storage is provided.

(e) The director may require sampling and monitoring for pollutants at any drain tile outfall, including but not limited to the following:

(i) CBOD5.

(ii) Total suspended solids.

(iii) E. coli.

(iv) Total inorganic nitrogen.

(v) Total phosphorus.