Rule 4123:1-3-22 | Woodworking machines, power saws, and other tools and equipment.

(A) Reserved.

(B) Definitions.

(1) "Cutting wheels" means organic bonded wheels designed for use with power driven equipment for a multitude of operations variously known as cutting, cutting-off, grooving, slotting, coping, jointing, etc.

(2) "Grinding wheels" means wheels composed of a uniform mixture of an abrasive material and a bond formed or molded into a single piece and designed for use with power driven equipment to reduce the dimensions of other materials held against them on the periphery or a side surface.

(C) Woodworking machines.

(1) Boring and mortising machines.

(a) Mortising machines (except hollow chisel mortisers).

Mortising machines, except hollow chisel mortisers shall be provided with thumb stops at each side of the chisel or with equivalent protection.

(b) Chain mortisers.

The top of the cutting chain and driving mechanism shall be guarded.

(c) Bits.

Bits on all automatic boring machines shall be guarded at the points of operation.

(d) Chuck design.

Safety bit chucks with no projecting set screws shall be used.

(e) This section shall not apply to lock and butt mortising machines.

(2) Sanding machines.

(a) Belt sanders.

Belt sanders shall have both pulleys guarded in such manner as to guard the points where the belt runs onto the pulleys. The edges of the unused run of the belt shall be guarded.

(b) Disc sanders.

Disc sanders shall have a guard so arranged as to enclose the periphery and back of the revolving disc, except such portion of the face of the disc above the table (if table is used) as may be required for the application of the material to be finished.

(c) Drum sanders.

Drum sanders shall have a guard so arranged as to enclose the revolving drum, except such portion of the drum above the table (if table is used) as may be required for the application of the material to be finished.

(3) Wood shapers.

(a) Cutting heads - guarding.

The cutting heads of each wood shaper, hand-fed panel raiser or other similar machine, not automatically fed, shall be guarded. The diameter of circular shaper guards shall be no less than the greatest diameter of the cutter. When single cutter knives in shaper heads are used, the shaper heads shall be balanced.

(b) Routers.

The pulleys, spindles, and cutting tools shall be guarded. Turnplates, jigs, and fixtures which keep the operator's hands out of the danger zone may be provided as an alternative.

(D) Power driven saws.

All cracked saw blades shall be removed from service.

(1) Circular saws.

The exposed portion of the saw blade above the table and under the table shall be guarded.

(a) Rip saw (manual feed).

A hood type guard shall be provided, the design of which shall:

(i) When not in use, cover the saw blade at all times;

(ii) When in use, automatically adjust itself to the thickness of and remain in contact with the material being cut when the stock encounters the saw blade, or may be a fixed or manually adjusted hood or guard provided the space between the bottom of the guard and the material being cut does not exceed three-eighths inch at any time;

(iii) The guard shall prevent a kick-back, or a separate attachment that will prevent a kick-back shall be provided. "Kick-back" devices shall be effective for all thicknesses of material that are cut;

(iv) A spreader shall also be provided and securely fastened at the rear of the saw in alignment with the saw blade, except where a roller wheel is provided at the back of the saw. The spreader shall be slightly thinner than the saw kerf and slightly thicker than the saw disc, to prevent the material from squeezing the saw blade.

(v) Alternate method.

Where the method of guarding as specified above is impossible, a substantial jig, fixture or template may be used which shall be designed to keep the hands of the operator out of the danger zone.

(b) Portable circular power saws.

Portable circular power saws shall have a hood type guard over the upper half of the blade. The lower half of the saw blade shall be guarded with a retracting guard which is designed to automatically adjust to the material being cut.

(c) Swing cutoff.

(i) A hood type guard shall be attached to the frame and shall completely cover the upper half of the saw blade, the arbor end, and the point of operation at all positions of the saw.

(ii) Automatic return.

The saw shall return automatically to the back of the table when released at any point of its travel without rebound of the blade.

(d) Radial arm saws.

(i) The upper hood shall completely enclose the upper portion of the blade down to a point that will include the end of the saw arbor. The upper hood shall be constructed in such a manner and of such material that it will protect the operator from flying splinters, broken saw teeth, etc., and will deflect sawdust away from the operator. The sides of the lower exposed portion of the blade shall be guarded to the full diameter of the blade by a device that will automatically adjust itself to the thickness of the stock and remain in contact with stock being cut.

(ii) The hood type guard shall be so designed as to prevent a kick-back when used for ripping or a separate attachment that will prevent a kick-back shall be provided. "Kick-back" devices shall be effective for all thicknesses of material that are cut.

(iii) A stop shall be installed which shall prevent the saw from traveling beyond the front edge of the table.

(iv) The direction of the saw rotation shall be conspicuously marked on the hood.

(v) The saw shall return automatically to the back of the table when released at any point of its travel without rebound of the blade.

(e) Masonry.

(i) Guarding.

A hood type guard shall be provided over the wheel of masonry saws.

(ii) Blades.

Only reinforced abrasive blades or diamond blades shall be used on masonry saws.

(2) Band saws and band knives.

All portions of the saw blade or band blade shall be enclosed or guarded, except for the working portion of the blade between the bottom of the guide rolls and the table. Band saw wheels shall be fully enclosed. The outside of the periphery of the enclosure shall be solid. The front and back of the band wheels shall be either enclosed by solid material or by wire mesh or perforated metal, the dimensions and material of which shall be in accordance with appendix I to rule 4123:1-3-05 of the Revised Code.

(E) Portable chain saws.

Portable chain saws shall have all guards and handles, as provided by the manufacturer, in place, all controls functioning properly and mufflers operative. Electrically powered chain saws shall comply with paragraph (H) of this rule.

(F) Power grinders.

(1) External grinding machines.

On all portable grinding machines used for external grinding, a substantial guard shall be provided unless the grinding wheels are equipped with protection flanges, bands or chucks except that these requirements shall not apply if grinding wheels are less than two inches in diameter and are operated at a peripheral speed not exceeding three thousand feet per minute (fpm). The exposure (unguarded portion) of the grinding wheel periphery shall be as small as the work will permit for external grinding. Where the nature of the work is such that the material acts as a shield to the periphery of the grinding wheel, the material shall be construed as constituting a guard and no additional guard shall be required.

(2) Bench or floor stand.

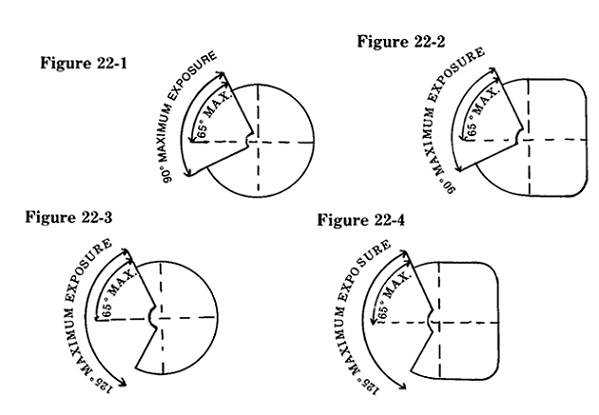

The angular exposure of the grinding wheel periphery and sides for safety guards used on machines known as bench or floor stands shall not exceed ninety degrees or one-fourth of the periphery and such exposure shall begin at a point no more than sixty-five degrees above the horizontal plane of the wheel spindle (see "Figures 22-1 and 22-2"), provided that whenever the nature of the work requires contact with the wheel below the horizontal plane of the spindle, the exposure shall not exceed one hundred twenty-five degrees (see "Figures 22-3 and 22-4").

(3) Work rests.

On off-hand grinding machines work rests shall be used to support the work. They shall be of rigid construction and designed to be adjustable to compensate for wheel wear. Work rests shall be kept adjusted to a maximum opening of one-eighth inch to prevent the work from being jammed between the wheel and the rest. The employer shall instruct the employee to securely clamp the work rest after each adjustment. The employer shall also instruct the employee not to adjust the work rest with the wheel in motion.

(G) Pneumatically powered tools.

All pneumatically powered portable tools shall be equipped with an automatic shutoff valve ("dead-man" control) so arranged as to close the air inlet valve when the pressure of the operator's hand is removed. Each tool shall be equipped with a retainer where accidental ejection is possible.

(H) Grounding.

All electrically powered portable tools and equipment with exposed noncurrent-carrying metal parts shall be grounded. Portable tools and equipment protected by an approved system of double insulation, or its equivalent, need not be grounded. Where such an approved system is employed the equipment shall be distinctively marked.

(I) Power cutoff and pressure control devices.

(1) Portable powered tools.

All hand-held powered drills, tappers, fastener drives, horizontal, vertical, and angle grinders with wheels greater than two inches in diameter, disc sanders with discs greater than two inches in diameter, belt sanders, reciprocating saws, saber, scroll, and jig saws with blade shanks greater than a nominal one-fourth inch, and other similarly operating powered tools shall be equipped with a constant pressure switch or control, and may have a lock-on control provided that turn-off can be accomplished by a single motion of the same finger or fingers that turn it on.

(2) Use of compressed air tools.

(a) In operations requiring the use of compressed air tools the wearing of eye protection is required in all cases.

(b) The employer shall instruct the employee that compressed air shall not be used for personal cleaning purposes.

(J) Portable pneumatically powered fasteners.

(1) Actuating mechanism.

(a) Two separate and distinct operations shall be required to activate the fastener. The final activating movement, such as depressing a trigger, shall be separate from the prerequisite that the fastener be held firmly against the work surface before it will operate.

(b) The fastener shall be designed so that it cannot fire during loading or during preparation to fire, or if the fastener should be dropped while loaded.

(2) Air hose.

Hose and hose connections used for conducting compressed air to utilization equipment shall be those designed for the pressure and service to which they are subjected.

(3) Pressure regulator.

The fastener shall be equipped with a pressure regulator or other device to prevent air pressure from exceeding the maximum design capacity of the fastener.

(K) Portable safety containers.

Approved portable safety containers shall be provided for handling flammable liquids with a flash point below one hundred forty degrees Fahrenheit in quantities of one gallon or more. The containers shall be legibly marked "flammable".

Last updated June 9, 2021 at 8:14 AM