Rule 4781-6-03.6 | Ductwork and plumbing and fuel supply systems.

(A) Field assembly.

Home manufacturers shall provide specific installation instructions for the proper field assembly of manufacturer-supplied and shipped loose ducts, plumbing, and fuel supply system parts that are necessary to join all sections of the home and shall be designed to be located underneath the home. The installation instructions shall be designed in accordance with applicable requirements of the MHCSS. Where manufacturer's installation instructions are not available or do not address an element of the installation, the Ohio plumbing code, the Ohio mechanical code, and this rule shall govern.

(B) Utility connections.

Refer to rule 4781-6-03.9 of the Administrative Code.

(C) Water supply.

(1) Crossover. Multi-section homes with plumbing in both sections require water-line crossover connections to join all sections of the home.

(2) Maximum supply pressure and reduction. When the local water supply pressure exceeds eighty pounds per square inch to the manufactured home, a pressure-reducing valve shall be installed.

(3) Mandatory shutoff valve.

(a) An identified and accessible shutoff valve shall be installed between the water supply and the inlet.

(b) The water riser for the shut-off valve connection shall be located underneath or adjacent to the manufactured home with the shut-off valve accessible within three feet of the point where the water supply enters the perimeter of the manufactured home or emerges from underground.

(c) The shutoff valve shall be a full-flow gate or ball valve, or equivalent valve.

(4) Freezing protection. Water line crossovers completed during installation shall be protected from freezing.

(a) If subject to freezing temperatures, the water connection shall be wrapped with insulation or otherwise protected to prevent freezing.

(b) In areas subject to freezing or subfreezing temperatures, exposed sections of water supply piping, shutoff valves, pressure reducers, and pipes in water heater compartments shall be insulated or otherwise protected from freezing.

(c) Use of pipe-heating cable. Only pipe-heating cable listed for the intended use shall be permitted to be used. It shall be fused or used with a fused plug and shall be installed in accordance with the cable manufacturer's installation instructions.

(5) Testing procedures.

(a) The water system shall be inspected and tested for leaks after completion at the site in accordance with the manufacturer's installation instructions. Where no manufacturer's installation manual test procedure is available, the test shall be performed in accordance with testing procedures provided on forms approved by the division.

(b) The water heater shall be disconnected when using an air-only test to prevent damage to the water heater for pressures above eighty psi.

(D) Drainage system.

(1) Crossovers. Multi-section homes with plumbing in more than one section require drainage system crossover connections to join all sections of the home.

(2) Assembly and support. If portions of the drainage system were shipped loose because the portions were necessary to join all sections of the home and designed to be located underneath the home, the portions shall be installed and supported in accordance with the manufacturer's home installation instructions or the division's rules.

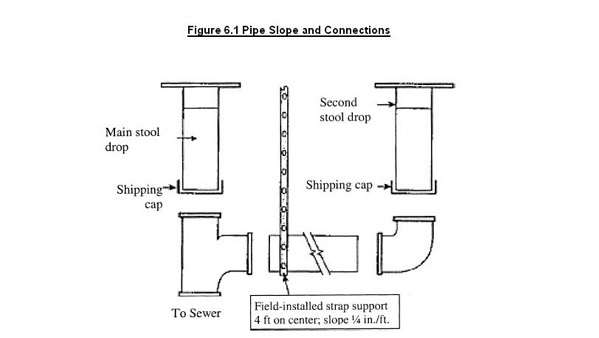

(3) Proper slopes. Drains shall be completed in accordance with manufacturer's home installation instructions or the division's rules.

(a) Drain lines shall not slope less than one-quarter inch per foot unless otherwise noted on the schematic diagram, as shown in figure 6.1 of this rule.

(b) A slope of one-eighth inch per foot may be permitted when a clean out is installed at the upper end of the run.

(4) Testing procedures.

The drainage system shall be inspected and tested for leaks after completion at the site in accordance with the manufacturer's installation instructions. Where no manufacturer's installation manual test procedure is available, the test shall be performed in accordance with testing procedures provided on forms approved by the division.

(E) Fuel supply system.

(1) Proper supply pressure. The gas piping system in the home is designed for a pressure that is at least ten inches of water column [5.8 ounces per square inch or 0.36 psi] and not more than fourteen inches of water column [eight ounces per square inch 0.5 psi]. If gas from any supply source exceeds, or could exceed, this pressure, a regulator shall be installed.

(2) Crossovers.

Multi-section homes with fuel supply piping in both sections require crossover connections to join all sections of the home.

(3) Testing procedures. The gas system shall be inspected and tested for leaks after completion at the site in accordance with the manufacturer's installation instructions. Where no manufacturer's installation manual test procedure is available, the test shall be performed in accordance with testing procedures on forms approved by the division.

(F) Ductwork connections.

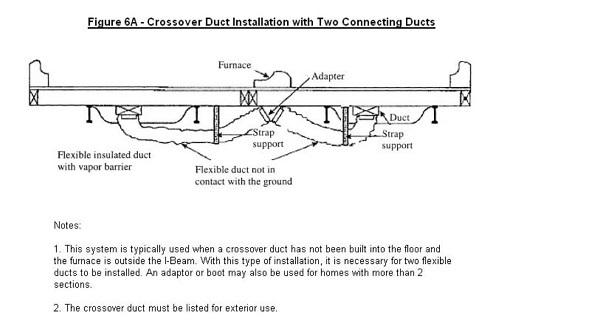

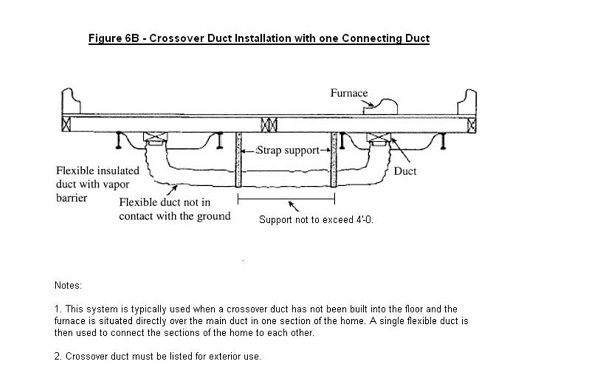

(1) Crossovers. Multi-section homes with ductwork in more than one section require crossover connections to complete the duct system of the home. All ductwork connections, including duct collars, shall be sealed to prevent air leakage. Galvanized metal straps or tape and mastics listed to UL 181 A or UL181 B shall be used around the duct collar and secured tightly to make all connections.

(2) If metal straps are used, the metal straps shall be secured with galvanized sheet metal screws.

(3) Metal ducts shall be fastened to the collar with a minimum of three galvanized sheet metal screws equally spaced around the collar.

(4) Air conditioning or heating ducts shall be installed in accordance with applicable requirements of the duct manufacturer's installation instructions.

(5) The duct shall be suspended or supported above the ground by straps or other approved means that are spaced at a maximum distance not to exceed four feet or as otherwise permitted by the installation instructions. When straps are used to support a flexible type duct, the straps shall be at least three-fourths of an inch wide and shall be installed such that the straps cannot slip between any two spirals and arranged under the floor to prevent compression or kinking in any location, as shown in figures 6A and 6B of this rule.

(6) Crossover ducts outside the thermal envelope of the manufactured home, in uninsulated basements or uninsulated crawlspaces, shall be insulated to an R-value of four or better in accordance with ASTM C-518, UL181 for flexible ducts or equal thermal protection and covered with a vapor retarder.

(7) In-floor or ceiling crossover duct connections shall be installed and sealed to prevent air leakage.

(8) Support of crossover ducts does not include resting loose on rocks, brick, blocks, or other materials resting on the ground.

(9) Floor joists shall not be notched or cut into in any way during the installation of on-site ductwork.

(10) Repair any tears in the outlining of ductwork and cover all exposed metal surfaces, boots, and connections with insulation with a minimum R-value of four and a vapor barrier.

Last updated July 7, 2021 at 8:38 AM