(A) Scope.

The purpose of this chapter of the Administrative Code is to provide reasonable safety for life, limb, and health of employees. In cases of practical difficulty or unnecessary hardship, the Ohio bureau of workers' compensation may grant exceptions from the literal specifications of the rules of this chapter to permit the use of other devices or methods when, in the opinion of the bureau, the equivalent protection is thereby secured.

The specific provisions of this chapter pertain to the employer for the protection of such employer's employees and no others and apply to all workshops and factories subject to the Workers' Compensation Act (sections 4123.01 to 4123.99 of the Revised Code). Specific provisions of other chapters of the Administrative Code adopted by the Ohio bureau of workers' compensation apply to the particular industry covered by any such other chapter, and, to the extent of conflict between this chapter and such other chapter, the latter will govern, but in all other respects this chapter is deemed to apply and the other to be a supplement of this chapter.

Installations or constructions built or contracted for prior to the effective date (shown at the end of each rule) of any specification are deemed to comply with the provisions of these rules if such installations or constructions comply either with the provisions of the current rules or with the provisions of any applicable rule which was in effect at the time contracted for or built.

(B) Definitions.

(1) "Access board (hot board)": a platform designed to be fastened to a pole or structure and having dielectric properties equal to dry wood.

(2) "Adjustable barrier guard": a barrier that is adjustable for each job setup or die setup.

(3) "Aerial device": any vehicle-mounted telescoping or articulating device which is used to position personnel at job sites.

(4) "Air contaminants": concentrations of dust, mist, fume, gas or vapor, or any combination thereof when suspended in the atmosphere.

(5) "Air-lift hammer": (see "gravity hammers").

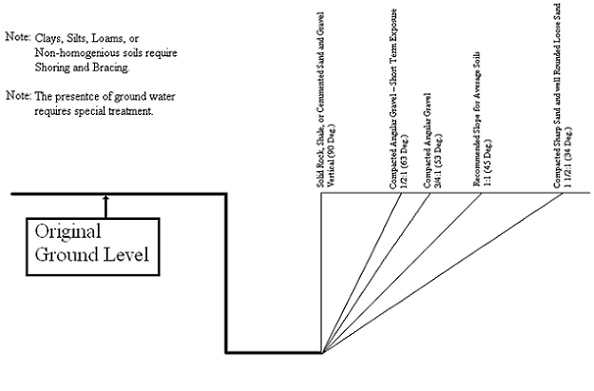

(6) "Angle of repose": the greatest angle above the horizontal plane at which unexcavated material will lie without sliding.

(7) "Anti-repeat": the part of the clutch/brake control system designed to limit a mechanical power press to a single stroke if the tripping means is held on the operating position. Anti-repeat requires release of all tripping mechanisms before another stroke can be initiated. Anti-repeat is also called "single stroke reset" or "reset circuit."

(8) "Approved": sanctioned, endorsed, accredited, certified, or accepted as satisfactory by a duly constituted and nationally recognized authority or agency.

(9) "Approved storage facility (magazine)": a facility for the storage of explosive materials covered by a license or permit issued under authority of the appropriate governmental agencies.

(10) "Bearer": a horizontal member of a scaffold upon which the platform rests and which may be supported by ledgers.

(11) "Blast area": the area in which explosives loading and blasting operations are being conducted.

(12) "Blaster": a person qualified to be in charge of and responsible for the loading and firing of a blast.

(13) "Blasting agent": any material or mixture consisting of a fuel and oxidizer intended for blasting, not otherwise classified as an explosive, and in which none of the ingredients are classified as an explosive, provided that the finished product, as mixed and packaged for use or shipment, cannot be detonated by means of a no. 8 test blasting cap when unconfined.

(14) "Blasting cap": (see "detonator").

(15) "Board-type drop hammer": (see "gravity hammers").

(16) "Boatswain's chair": a seat supported by slings attached to a suspended rope, designed to accommodate one employee in a sitting position.

(17) "Bolster plate": the plate attached to the top of the bed of a power press having drilled holes or T-slots for attaching the lower die or die shoe.

(18) "Brace":

(a) Scaffold

A tie that holds one scaffold member in a fixed position with respect to another member.

(b) Trench

The horizontal members of the shoring system with ends bearing against the uprights or stringers.

(19) "Brake (mechanical power press)": the mechanism used to stop and hold the crankshaft, either directly or through a gear train, when the clutch is disengaged.

(20) "Brake monitor": a sensor designed, constructed, and arranged to monitor the effectiveness of a mechanical power press braking system.

(21) "Bulldozers": stationary power-driven machines used chiefly for bending operations. They have a movable head operated by links attached to the main drive gears and moving in a horizontal plane.

(22) "Circuit" a conductor or system of conductors through which an electric current flows or may flow.

(23) "Cleats": ladder crosspieces of rectangular cross-sections placed on edge on which an employee may step in ascending or descending.

(24) "Climbers": lineman's tools used on the legs and feet to enable the lineman to climb wooden poles.

(25) "Clutch": the coupling mechanism used on a mechanical power press to couple the flywheel to the crankshaft, either directly or through a gear train.

(26) "Collector" (see "separator").

(27) "Conductor": metallic material suitable for carrying an electric current.

(28) "Confined space": meets all of the following three criteria:

(a) Is large enough and so configured that an employee can bodily enter and perform assigned work;

(b) Has limited or restricted means for entry or exit (for example, tanks, vessels, silos, storage bins, hoppers, vaults and pits are spaces that may have limited means of entry.); and

(c) Is not designed for continuous employee occupancy.

(29) "Contact distance (electrical)": that distance within which contact in doing the work or contact in the event of reaching, slipping, or falling may possibly occur.

(30) "Control system": sensors, manual input, and mode selection elements, interlocking and decision-making circuitry, and output elements to a mechanical power press operating mechanism.

(31) "Counterbalance": the mechanism that is used to balance or support the weight of the connecting rods, slide, and slide attachments on a power press.

(32) "Coupler": a device for locking together the component parts of a tubular metal scaffold.

(33) "Cutting-off wheels": organically bonded wheels designed for use with power-driven equipment for a multitude of operations variously known as cutting, cutting-off, grooving, slotting, coping, jointing, etc.

(34) "Danger zone": the point of operation where a known hazard exists.

(35) "Deenergized": free from any electrical connection to a source of potential different from that of the earth.

(36) "Designated employee": an employee selected or assigned by the employer or the employer's representative as being qualified to perform specific duties.

(37) "Detonating cord": a flexible cord containing a center core of high explosives and used to initiate other explosives.

(38) "Detonator": any device containing a detonating charge that is used for initiating detonation in an explosive; the term includes, but is not limited to, electric blasting caps of instantaneous and delay types, blasting caps for use with safety fuse, detonating cord delay connectors, and non-electric instantaneous and delay blasting caps.

(39) "Dielectric": a nonconductor of electric current which will not absorb moisture, such as fiberglass, or equivalent.

(40) "Die setting": the process of placing or removing dies in or from a power press, and the process of adjusting the dies, other tooling, and safeguarding means to cause them to function properly and safely.

(41) "Die shoe": a plate or block upon which a die holder is mounted. A die shoe functions primarily as a base for the complete die assembly, and, when used, is bolted or clamped to the bolster plate or the face of the slide.

(42) "Dockboard (bridge plate)": a movable plate (usually metal) for bridging the gap between motor vehicle or freight car and a dock or loading platform.

(43) "Energized": anything connected to an electrical source having a greater potential than that of the earth.

(44) "Excavation": any man made cavity or depression in the earth's surface, including its sides, walls, or faces, formed by earth removal and producing unsupported earth conditions by reason of the excavation. If installed forms or similar structures reduce the depth-to-width relationship, an excavation may become a trench.

(45) "Exhaust system": includes suction systems, hoods, ducts, fans, separators, receptacles, and other parts necessary for the proper installation and operation thereof.

(46) "Explosive": any chemical compound or mixture that is intended for the purpose of producing an explosion.

(47) "Exposed to contact": the location of the material or object which, during the course of operation, is accessible to an employee in performance of the employee's regular or assigned duty.

(48) "Face of slide": the bottom surface of the slide to which the punch or upper die of a power press is generally attached.

(49) "Factor of safety": the ratio between the ultimate breaking stress and the working stress of the material, structure, or device. For example, the term "factor of safety of four" means that the material, structure, or device is constructed of such strength that the maximum load will be one-fourth the designed ultimate breaking load. Where other factors of safety appear, they will apply in the same manner. The standard of "The American Society for Testing and Materials (ASTM)" will be used in determining the strength of material except as otherwise provided herein.

(50) "Feed rolls": in-running rolls which perform no other function than to feed material to the point of operation.

(51) "Feeding": the process of placing or removing material within or from the point of operation. This may be done automatically, semi-automatically, or manually.

(52) "Fire-resistance rating": the measured time in hours or fractions thereof that the material or construction will withstand fire exposure, as determined by fire tests conducted in conformity with recognized standards.

(53) "Fire-resistive construction": a method of construction which prevents or retards the passage of hot gases or flames as defined by the fire-resistance rating.

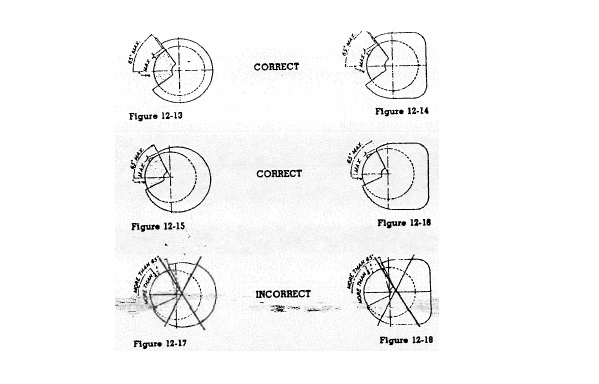

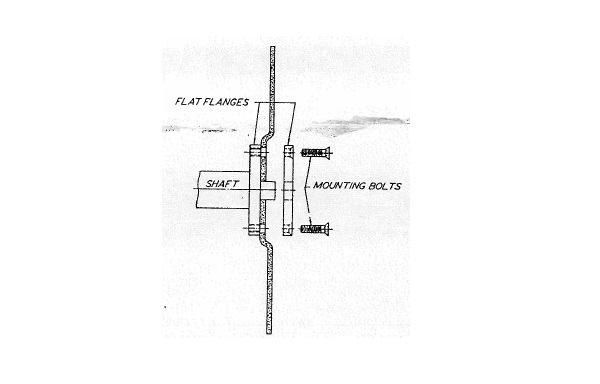

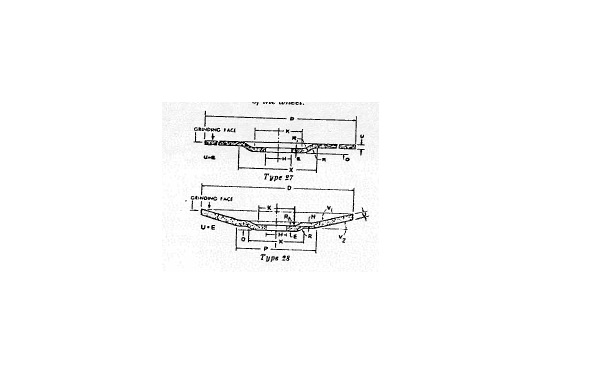

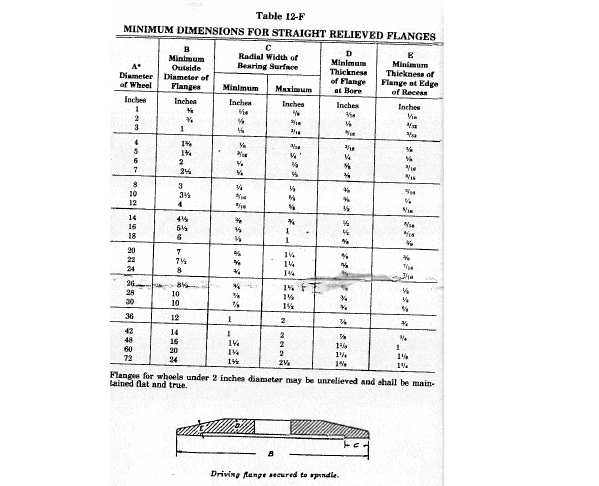

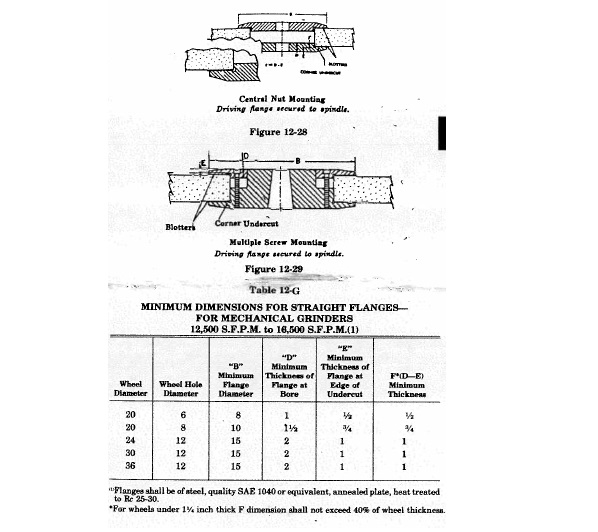

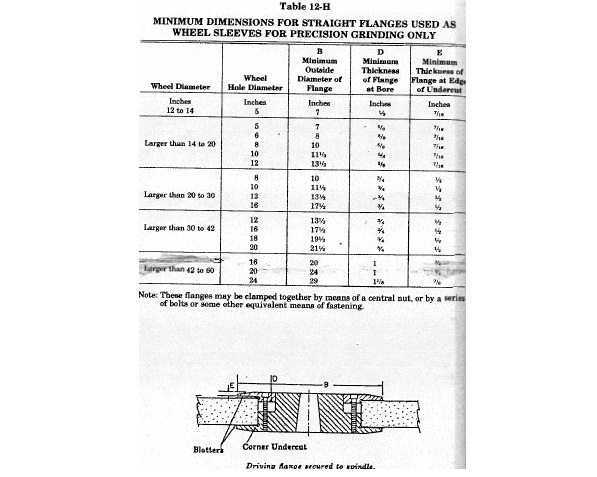

(54) "Flanges": collars, discs, or plates between which grinding wheels are mounted and are referred to as adaptor, sleeve, or back-up type.

(55) "Floor hole": A gap or open space in a floor, roof, horizontal walking-working surface, or similar surface that is two inches or more in its least dimension.

(56) "Floor opening": an opening measuring twelve inches or more in its least dimension, in any floor, platform, pavement, or yard, through which a person may fall; such as a hatchway, stair or ladder opening, pit or large manhole.

(57) "Foot control (part revolution clutch press)": the foot-operated control mechanism designed to be used with a clutch or clutch/brake control system.

(58) "Foot pedal (full revolution clutch press)": the foot-operated lever designed to operate the mechanical linkage that trips a full revolution clutch.

(59) "Forging": the product of work on metal formed to a desired shape by impact or pressure in hammers, forging machines (upsetters), presses, rolls, and related forming equipment.

(60) "Forging presses": a class of forging equipment wherein the shaping of metal between dies is performed by mechanical or hydraulic pressure.

(61) "Full revolution clutch (mechanical power press)": a type of clutch that, when tripped, cannot be disengaged until the crankshaft has completed a full revolution and the press slide a full stroke.

(62) "Fumes": small solid particles formed by the condensation of vapors of solid materials.

(63) "Gas": a formless fluid which tends to occupy an entire space uniformly at ordinary temperatures and pressures.

(64) "Gate" or "movable barrier device": a movable barrier arranged to enclose the point of operation before a power stroke can be started.

(65) "Grab bars": individual handholds placed adjacent to or as an extension above ladders for the purpose of providing access beyond the limits of the ladder.

(66) "Gravity hammers": A class of forging hammer wherein energy for forging is obtained by the mass and velocity of a freely falling ram and the attached upper die. Examples: board-type drop hammers and air-lift hammers.

(67) "Ground":

(a) "Ground connection": the equipment used in establishing a path between an electric circuit or equipment and earth. A ground connection consists of a ground conductor, a ground electrode, and the earth which surrounds the electrode.

(b) "Grounded": connected to earth by a ground connection.

(c) "Grounded effectively": connected to earth through a ground connection or connections of sufficiently low impedance and having sufficient current-carrying capacity to prevent the building up of voltages which may result in undue hazard to connected equipment or to employees.

(68) "Grounding conductor": a conductor which is used to connect the equipment or the wiring system with a grounding electrode or electrodes.

(69) "Guard": the covering, fencing, railing, or enclosure which shields an object from accidental contact. (See also "safety guard.")

(70) "Guarded": means that the object is covered, fenced, railed, enclosed, or otherwise shielded from accidental contact.

(71) "Guide post": the pin attached to the upper or lower die shoe, operating within the bushing on the opposing die shoe, to maintain the alignment of the upper and lower dies of a power press.

(72) "Handhold (handgrip)": a device attached to a manlift which can be grasped by the passenger to provide a means of maintaining balance.

(a) "Closed type": a cup-shaped device into which the passenger may place his fingers, open at the top in the direction of travel of the step for which it is to be used, and closed at the bottom.

(b) "Open type": one which has a handgrip surface fully exposed and capable of being encircled by the passenger's fingers.

(73) "Handrail": a a lengthwise member mounted directly on the wall, floor or partition by means of brackets that will furnish an adequate handhold for anyone grasping it to avoid falling.

(74) "Hazardous concentrations (as applied to air contaminants)": concentrations of air contaminants which are in excess of established occupational exposure limits.

(75) "Head protection devices":

(a) "Bump cap or hat": a thin-shelled plastic headgear worn to provide protection to the head from bumps or lacerations but does not meet the specifications for protective helmets.

(b) "Crown straps": that part of the suspension which passes over the head.

(c) "Hair enclosure": a hat or cap (other than a protective helmet or bump cap) or a hairnet specifically designed to protect the wearer from entanglement in moving parts of machines, equipment, or from exposure to sparks, hot metal, or ignition.

(d) "Protective helmet": a rigid headgear also known as a safety or hard hat, or as a safety or hard cap, that is worn to provide protection for the head, or portions thereof, against impact, flying articles, or electric shock, or any combination thereof, and which is held in place by a suitable suspension.

(e) "Suspension": the internal cradle of a protective helmet or bump cap which holds it in place on the head and is made up of the headband and crown straps.

(76) "Hood": that part of an exhaust system into which the contaminated air or dust, fumes, mist, vapor, or gas first enters.

(77) "Hot line (live line) tools": those tools which are especially designed for work on energized high voltage conductors and equipment.

(78) "Inch": an intermittent motion imparted to the slide (on mechanical power presses using part revolution clutches) by momentary operation of the inch operating means.

(79) "Kickouts": accidental release or failure of a shore or brace used in trenching.

(80) "Ladder":

(a) "Extension ladder": a portable ladder, adjustable in length. It consists of two or more sections traveling in guides or brackets so arranged as to permit length adjustment. Its size is designated by the sum length of the sections measured along the side rails.

(b) "Extension trestle ladder": a self-supporting portable ladder, adjustable in length, consisting of a trestle ladder base and a vertically adjustable single ladder, with an effective means for locking the ladders together. The size is designated by the length of the trestle ladder base.

(c) "Fixed ladder": a ladder permanently attached to a structure, building, or equipment.

(i) "Ladder cage": an enclosure which encircles the climbing space of the ladder and is securely fastened to the side rails of the ladder or to the structure.

(ii) "Ladder well": a permanent complete enclosure around a fixed ladder, which is securely fastened to the walls of the well.

(d) "Individual-rung ladder": a fixed ladder, each rung of which is individually attached to a structure, building, equipment, or manhole.

(e) "Platform stepladder": a modification of a portable stepladder with a working platform provided near the top.

(f) "Rail ladder": a fixed ladder consisting of side rails joined at regular intervals by rungs or cleats and fastened in full length or in sections to a building, structure, or equipment.

(g) "Sectional ladder": a portable ladder, nonadjustable in length, consisting of two or more sections so constructed that the sections may be combined to function as a single ladder. Its size is designated by the overall length of the assembled sections.

(h) "Side-rolling ladder": a semifixed ladder, nonadjustable in length, supported by attachments to a guide rail, which is generally fastened to shelving, the plane of the ladder being also its plane of motion.

(i) "Side-step ladder": one from which an employee getting off at the top steps sideways in order to reach the landing.

(j) "Single ladder": a portable, nonadjustable ladder consisting of only one section.

(k) "Stepladder": a self-supporting portable ladder, nonadjustable in length, having flat steps or treads and a hinged back. Its size is designated by the overall length of the ladder measured along the front edge of the side.

(l) "Through ladder": one from which an employee getting off at the top steps through the rails in order to reach the landing.

(m) "Trestle ladder": a self-supporting portable ladder, nonadjustable in length, consisting of two sections hinged at the top to form equal angles with the base. The size is designated by the length of the side rails measured along the front edge.

(81) "Lanyard": a flexible line of rope, wire rope, or strap, which generally has a connector at each end for connecting the body belt or body harness to a deceleration device, lifeline, or anchorage.

(82) "Leading wire": an insulated wire used between the electric power source and the electric blasting cap circuit.

(83) "Ledger (stringer)": a horizontal scaffold member which extends from post to post and which supports the putlogs or bearer forming a tie between the posts.

(84) "Lifeline": a component consisting of a flexible line for connection to an anchorage at one end to hang vertically (vertical lifeline), or for connection to anchorages at both ends to stretch horizontally (horizontal lifeline) and which serves as a means for connecting other components of a personal fall arrest system to the anchorage.

(85) "Limit switch": a device on a manlift for the purpose of cutting off the power to the motor and applying the brake to stop the carrier in the event that a loaded step passes the terminal landing.

(86) "Magazine": (see "approved storage facility").

(87) "Manlift": a device consisting of a power-driven endless belt with steps or platforms and handholds attached to it for the transportation of personnel from floor to floor.

(88) "Mist": small droplets of materials that are ordinarily liquid at normal temperature and pressure.

(89) "Nominal": in name or form, but not in fact; for example, a piece of lumber described as four inches by four inches but which, in fact, meets a standard which is less.

(90) "Non-current carrying": not intended to be energized.

(91) "Off-hand grinding": the grinding of any material or part which is held in the operator's hand.

(92) "Operator": any employee assigned or authorized to work at the specific equipment.

(93) "Part revolution clutch": a type of clutch that can be disengaged at any point before the crankshaft has completed a full revolution and the press slide a full stroke.

(94) "Pinch, nip, or shear point": the point or points at which it is possible to be caught between the moving parts of a machine, or between the moving and stationary parts of a machine, or between the material and the moving part or parts of a machine.

(95) "Pitch": the included angle between the horizontal and the ladder measured from the opposite side of the ladder from the climbing side.

(96) "Platform": a working space for employees elevated above the surrounding floor or ground.

(97) "Point of operation": the area where material is actually positioned and work is being performed during any process.

(98) "Polishing wheels": wheels designed for use with power-driven equipment to apply a luster or polish to materials.

(99) "Portable explosive-actuated fastening tool": a tool which depends upon an explosive charge to propel or discharge a stud, pin, or fastener, for the purpose of impinging it upon, affixing it to, or penetrating another object or material.

(a) "High-velocity tool": a tool or machine which, when used with a load, propels or discharges a stud, pin, or fastener at velocities in excess of three hundred feet per second.

(b) "Low-velocity tool": a tool or machine which, when used with a load, propels or discharges a stud, pin, or fastener at velocities not in excess of three hundred feet per second.

(100) "Power shears": power-driven machines used for cutting bars, slabs, sheets, or other material.

(101) "Presence sensing device": a device that creates a sensing field or area and deactivates the clutch control and activates the brake of a power press when any part of the operator's body or a hand tool is within such field or area.

(102) "Press": a powered machine that shears, punches, forms, or assembles metal or other material by means of cutting, shaping, or by combination dies attached to slides. A press consists of a stationary bed or anvil, and a slide (or slides) having a controlled reciprocating motion toward and away from the bed surface, the slide being guided in a definite path by the frame of the press.

(103) "Primed cartridge": a cartridge of explosives to which a detonator has been attached as a means of firing.

(104) "Protective shield or guard": a device, attached to the muzzle end of a portable explosive-actuated fastening tool, which is designed to confine flying particles.

(105) "Pull-out device": a mechanism attached to the operator's hands and connected to the upper die or slide of a power press, that is designed, when properly adjusted, to withdraw the operator's hands as the dies close when the operator's hands are inadvertently within the point of operation.

(106) "Railing": a vertical barrier erected above exposed edges of a floor opening, wall opening, ramp, platform, or runway to prevent falls of employees.

(107) "Rated load (roof car suspended platforms)": the combined weight of employees, tools, equipment, and other material which the working platform is designed to lift.

(108) "Rated speed": the speed for which a tool or piece of equipment is designed.

(109) "Repeat": an unintended or unexpected successive stroke of a power press resulting from a malfunction.

(110) "Respiratory devices":

(a) "Air-purifying respirator": a respirator with an air-purifying filter, cartridge, or canister that removes specific air contaminants by passing ambient air through the air-purifying element. These include:

(i) "Mechanical-filter respirator": a respirator which provides respiratory protection against particulate matter, such as nonvolatile dust, mists, or metal fumes.

(ii) "Chemical-cartridge respirator": a respirator equipped with a filter, sorbent, or catalyst, or combination of these items, which removes specific contaminants from the air passing through the air-purifying element.

(b) "Supplied-air respirator": an atmosphere-supplying respirator for which the source of breathing air is not designed to be carried by the user.

(c) "Self-contained breathing apparatus": an atmosphere-supplying respirator for which the source of breathing air is designed to be carried by the user.

(111) "Roof car": (see "scaffolds").

(112) "Roof car suspended platform": (see "scaffolds").

(113) "Roof-powered platform": (see "scaffolds").

(114) "Runway": a passageway for employees elevated above the surrounding floor or ground level.

(115) "Safety belt" or " body belt": a strap with means both for securing it around the waist and for attaching it to a lanyard, lifeline, or deceleration device.

(116) "Safety block": a prop that, when inserted between the upper and lower dies of a power press or between the bolster plate and the face of the slide, prevents the slide from falling of its own dead weight.

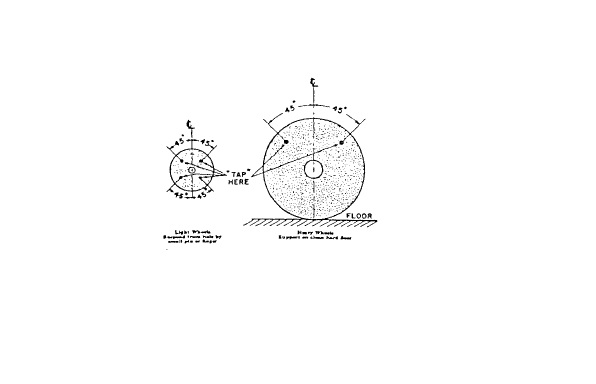

(117) "Safety guard (grinding wheel)": a device designed to restrain the pieces of a grinding wheel in the event the wheel is broken in operation.

(118) "Safety harness" or "body harness": a design of straps which may be secured about the employee in a manner that will distribute the fall arrest forces over at least the thighs, pelvis, waist, chest and shoulders with means for attaching it to other components of a personal fall arrest system.

(119) "Scaffold":

(a) " Mobile scaffold": a powered or unpowered, portable, caster or wheel-mounted supported scaffold.

(b) "Mobile work platform": generally a fixed work level, one frame high, on casters or wheels, with bracing diagonally from platform to vertical frame.

(c) "Roof car": a structure for the suspension of a working platform, providing for its horizontal movement to working positions.

(d) "Roof car suspended platform": equipment to provide access to the exterior of a building consisting of a suspended power-operated working platform, a roof car, and the operating and control devices.

(e) "Roof-powered platform": the working platform of a roof car suspended platform having the raising and lowering mechanism located on a roof car.

(f) "Self-powered platform": a working platform, of a roof car suspended platform, having the raising and lowering mechanism located on the working platform.

(g) "Swinging scaffold": a power- or manually operated platform suspended by two or more lines and independent of the building except for attachment at the roof or parapet.

(h) "Tube and coupler scaffold": an assembly consisting of tubing which serves as posts, bearers, braces, ties, and runners, a base supporting the posts, and special couplers which serve to connect the uprights and to join the various members.

(i) "Tubular welded frame scaffold": a sectional panel, or frame metal scaffold substantially built up of prefabricated welded sections which consist of posts and horizontal bearer with intermediate members. Panels or frames shall be braced with diagonal or cross braces.

(j) "Two-point suspension scaffolds": a scaffold suspended from overhead supports, the platform of which is supported by stirrups or hangers at two points to permit raising or lowering.

(120) "Securely fastened": the object or thing referred to is substantially fixed in place.

(121) "Self-powered platform": (see "scaffold").

(122) "Separator (collector)": that part of an exhaust system, the purpose of which is to separate material from the air which conveys it.

(123) "Shaft": an excavation made from the surface of the ground the longer axis of which forms an angle with the vertical of no more than forty-five degrees.

(124) "Shall": to be construed as mandatory.

(125) "Sheet pile": a pile, or sheeting, that may form one of a continuous interlocking line, or a row of timber, concrete, or steel piles, driven in close contact to provide a tight wall to resist the lateral pressure of water, adjacent earth, or other materials.

(126) "Sides," "walls," or "faces": the vertical or inclined earth surfaces formed as a result of trenching or excavation work.

(127) "Single-stroke mechanism (mechanical power press)": an arrangement used on a full revolution clutch to limit the travel of the slide to one complete stroke at each engagement of the clutch.

(128) "Slide": the main reciprocating member of a power press. A slide is also called a ram, plunger, or platen.

(129) "Sling": an assembly which connects the load to the material handling equipment.

(130) "Split-rail switch": an electric limit switch operated mechanically by the rollers of manlift steps. It consists of an additional hinged or "split" rail, mounted on the regular guide rail, over which the step rollers pass. It is springloaded in the "split" position. If the step supports no load, the rollers will "bump" over the switch; if a loaded step should pass over the section, the split rail will be forced straight, tripping the switch and opening the electrical circuit.

(131) "Standard guard railing": a substantial barrier, constructed in accordance with paragraph (E) of rule 4123:1-5-02 of the Administrative Code.

(a) "Top rail": the top lateral member of a standard guard railing.

(b) "Intermediate rail": the lateral member or members of a standard guard railing, installed at intervals of no more than twenty-one inches.

(132) "Steam hammers": a type of drop hammer where the ram is raised for each stroke by a double-action steam cylinder and the energy delivered to the workpiece is supplied by the velocity and weight of the ram and attached upper die driven downward by steam pressure. Energy delivered during each stroke may be varied.

(133) "Stop control": an operator control on a mechanical power press designed to immediately deactivate the clutch control and activate the brake to stop slide motion.

(134) "Stripper": a mechanism or die part on a power press for removing the parts or material from the punch.

(135) "Stud, pin, or fastener (as used in portable fastening tools)": a fastening device specifically designed and manufactured for use in portable explosive-actuated fastening tools.

(136) "Substantial (referring to material things)": constructed of such strength, or of such materials, and of such workmanship that the object will withstand the wear, usage, or shock for which it is designed.

(137) "Sweep device": a single or double arm (rod) attached to the upper die or slide of the press and designed to move the operator's hands to a safe position as the dies close, if the operator's hands are inadvertently within the point of operation. The sweep device may not be used for point of operation safeguarding.

(138) "Swinging scaffold": (see "scaffold").

(139) "Toeboard": a vertical barrier erected along exposed edges of a floor opening, platform, runway, ramp, or scaffold to prevent falls of material.

(140) "Travel" (manlifts): the distance between the centers of the top and bottom pulleys.

(141) "Traveling cable": a cable made up of electrical or communication conductors or both, and providing electrical connection between the working platform and the roof car or other fixed point.

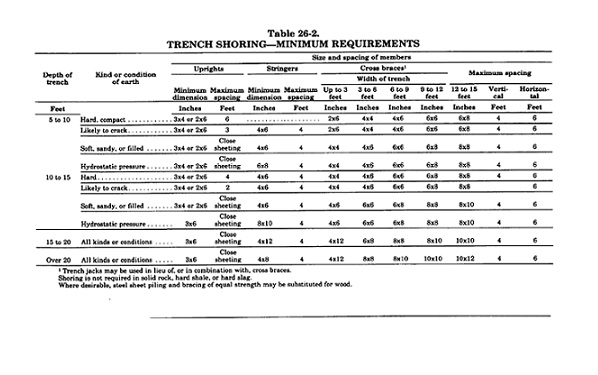

(142) "Trench (when used as a noun)": a narrow excavation made below the surface of the ground. In general, the depth is greater than the width, but the width of a trench at the bottom is no greater than fifteen feet.

(143) "Trench boxes (safety cages, trench shields)": a shoring system composed of steel plates and bracing, welded or bolted together, which can be moved along as work progresses and protects employees from movement of earth and cave-ins.

(144) "Trench jack": a screw or hydraulic-type jack used as cross bracing in a trench shoring system.

(145) "Turnover bar": a bar used in die setting to turn manually the crankshaft of a mechanical power press.

(146) "Two-point suspension scaffold": (see "scaffold").

(147) "Unitized tooling": a type of die in which the upper and lower members are incorporated into a self-contained unit so arranged as to hold the die members in alignment.

(148) "Uprights": the vertical members of a shoring system.

(149) "Upsetting machines (forging machines, headers)": a type of forging equipment in which the main forming energy is applied horizontally to the workpiece which is gripped and held by prior action of the dies.

(150) "Ventilation":

(a) "Dilution ventilation": ventilation provided to reduce the concentration of air contaminants in the atmosphere of all or part of the place of employment.

(b) "General ventilation": ventilation of the general atmosphere in the place of employment.

(c) "Local exhaust ventilation": that type of ventilation in which suction is applied at the point of generation or escape of air contaminants.

(151) "Wales (stringers)": the horizontal members of a shoring system with sides bearing against the uprights or earth.

(152) "Wall and chute openings": openings in any wall or partition from which there is a drop of more than four feet and which are thirty inches or more in height and eighteen inches or more in width through which an individual may inadvertently fall. Windows will not be considered wall openings except when located at the foot of any flight of stairs or at any platform on stairs. Where windows or openings are filled in with glass block, metal frame with sash bars, or wire mesh types, they will not be considered wall openings.

(153) "Wall hole": an opening less than thirty inches but more than one inch high, of unrestricted width, in a wall or partition, such as a ventilation hole or drainage scupper.

Last updated June 30, 2023 at 12:20 AM