Rule 3701-29-12 | Tanks, pumps and controls, and building sewers.

(A) Tanks subject to this chapter including, but not limited to, septic tanks, dosing tanks, pump vaults, HSTS holding tanks and privy vaults, grease traps or other applicable tanks shall be manufactured to be watertight and structurally sound in accordance with division (A)(17) of section 3718.02 of the Revised Code.

(B) Except as otherwise specified in rule, tanks shall be composed of materials, manufacture, physical design requirements and joint and tank connections that are in accordance with one of the following:

(1) ASTM C 1227;

(2) IAPMO/ANSI Z1000; material property standard;

(3) CAN/CSA-B66;

(4) ASTM Standard C 1613 for concrete grease interceptors; or

(5) Other standards approved by the director.

(C) Septic tanks used in a STS shall be labeled in accordance with ASTM C 1227, IAPMO/ANSI Z1000, or CAN/CSA-B66 and shall comply with the following requirements and specifications:

(1) Minimum liquid capacities:

(a) One to two bedrooms - one thousand gallons in one or two compartments.

(b) Three bedrooms - one thousand five hundred gallons in two tanks or compartments.

(c) Four to five bedrooms - two thousand gallons in two tanks or compartments.

(d) Six or more bedrooms - two thousand five hundred gallons plus an additional two hundred fifty gallons of tank capacity for each bedroom in two tanks or compartments.

(e) SFOSTS - one thousand gallons minimum in two tanks or compartments with at least two and one-half times the daily design flow.

(2) In two compartment tanks, the first compartment shall not be less than one half or more than two-thirds of the total capacity of the septic tank and the transfer port in the center wall shall ensure transfer of liquid from the clear zone only. When using two tanks, the septic tanks shall be connected in series.

(3) The septic tank outlet, or the outlet of the last septic tank in series, shall include an effluent filter device that retains solids greater than one sixteenth inch in size. Effluent filter devices shall be certified to ANSI/NSF Standard 46 or be approved by the director. Effluent filter devices shall be sized to meet the estimated daily design flow for the system that the septic tank is used in.

(D) Access openings, watertight risers, and lids shall be installed above the inlet and outlet of the tank in accordance with the following:

(1) Access openings and risers shall provide a minimum twelve inch clear opening and allow adequate space for pumping of the tank and inspection and maintenance except for access openings of pretreatment components as specified in paragraph (J) of rule 3701-29-13 of the Administrative Code. Clear opening means the point at the smallest diameter within the access opening.

(2) The connection of the riser to the tank and the connection of additional riser sections shall be watertight and prevent vertical and lateral movement of the riser.

(3) Riser joints must be watertight and use a gasket and/or sealant.

(4) Risers shall extend either to grade or above grade in a manner to prevent infiltration of surface or ground water.

(5) The cover or riser lid shall weigh a minimum of fifty pounds or be secured by mechanical means against unauthorized access.

(E) An access opening, watertight riser, and cover shall be provided above the compartment wall with a minimum twelve inch clear opening to allow for adequate pumping, inspection, and maintenance in a two compartment tank unless the transfer port in the center wall is a pass through opening that allows a shared liquid level in both compartments.

(F) Tanks shall be bedded, installed, and backfilled in accordance with manufacturer specifications and the product approval to assure the structural strength integrity of the tank. The tank shall be reasonably level to ensure the invert of the tank outlet is lower than the invert of the tank inlet.

(G) After installation, the director or a board of health may require watertight field testing of any STS tank due to installation or pipe connection problems provided the testing is conducted in accordance with the manufacturer's field testing procedures provided as part of the product approval.

(H) One year after the effective date of this rule, all tanks used in STS shall be approved by the director. The department of health shall maintain a list of approved tank models. A manufacturer's request submitted to the department of health for tank approval shall include, but is not limited to:

(1) A complete application form as developed by the department of health;

(2) Structural and physical design information, including tank or component buoyancy calculations and associated anti-buoyancy measures, design drawings and material specifications for each model size and configuration to demonstrate compliance with this rule;

(3) Documentation of the total liquid capacity and tank volumes calibrated in one inch increments for each tank;

(4) A written watertight field test procedure. Manufacturers of precast concrete tanks may use the test procedure specified in ASTM C 1719;

(5) Detailed written installation instructions including but not limited to bedding and backfilling requirements, product specific procedures to address buoyancy concerns with the tank, and identification of all site and installation conditions where these procedures are necessary;

(6) Verification of tank structural strength and integrity for expected internal and external loads by proof of compliance with one of the following assurance review methods:

(a) Process assurance review. Annual certification of the manufacturer by the national precast concrete association, IAPMO research and testing, CSA quality management institute, or other methods approved by the director;

(b) Product assurance review. Certification of compliance with one of the following standards, as appropriate, by a registered professional engineer or ANSI approved testing facility for each model of septic tank:

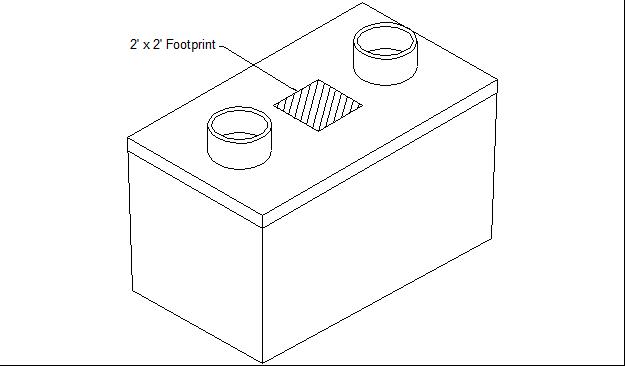

(i) ASTM C-1227 standard specifications for precast concrete septic tanks. The product assurance review under ASTM C-1227 shall include submission of results from structural proof testing which has been witnessed and certified by a registered professional engineer. The structural proof test shall consist of applying a negative air pressure (vacuum) and/or weight applied to the top of the tank to a determined load factor. For standard tanks designed to be buried with one foot to four feet of earthen cover, the calculated load factor requires that a tank be tested to a negative air pressure of four inches plus the placing of two thousand pounds of weighted material on a footprint of two feet by two feet placed in the center of the top of the tank as shown in figure 1. The calculated load factor shall be three hundred pounds per square foot lateral loads, and eight hundred pounds per square foot of top loading. The tank shall be certified as being structurally sound if it holds the pressure and weight for five minutes. The testing performed under this provision is intended to only be performed in the controlled environment of in-plant testing conforming to industry accepted test procedures;

Figure 1.

(ii) IAPMO/ANSI Z1000 standard for prefabricated septic tanks;

(iii) CAN/CSA-B66 for prefabricated septic tanks and sewage holding tanks; or

(iv) ASTM Standard C 1613 for concrete grease interceptors;

(c) Submission of written certification of tank designs or drawings assuring structural strength and integrity for anticipated internal and external loads by a registered professional engineer. Certification shall include the reviewed designs and drawings and be stamped with the registered professional engineer's seal.

(7) Documentation and verification of water-tightness testing by proof of compliance with one of the following assurance review methods:

(a) Process assurance review. Annual certification of the manufacturer by the national precast concrete association, IAPMO research and testing, CSA quality management institute, or other methods approved by the director.

(b) Product assurance review. Certification of compliance with one of the following standards, as appropriate, by a registered professional engineer or ANSI approved testing facility for each model of tank:

(i) ASTM C-1227 standard specifications for precast concrete septic tanks unless proven under paragraph (H)(6)(b)(i) of this rule;

(ii) IAPMO/ANSI Z1000 property standard for prefabricated septic tanks;

(iii) CAN/CSA-B66 for prefabricated septic tanks and sewage holding tanks; or

(iv) ASTM Standard C 1613 for concrete grease interceptors.

(c) Field assurance review. Signed written certification provided by the manufacturer that all STS tanks shall be field tested as watertight in accordance with either ASTM C-1719 for precast concrete tanks, IAPMO/ANSI Z1000 standard for prefabricated septic tanks, CAN/CSA-B66 for prefabricated septic tanks and sewage holding tanks, or other methods approved by the director and as appropriate for the material and manufacture of the tank.

(8) Identification of methods for tank repair and/or replacement in the event of watertight test, load or installation failure. Repairs of tanks shall be performed by the manufacturer in a manner ensuring that the repaired tank will conform to the requirements of these regulations.

(9) Any additional information as required by the director.

(I) Unless there is evidence of noncompliance with this rule and when there has been no change in the design or materials used in the manufacture of the tank, the department of health approval shall remain valid and a septic tank shall remain on the list upon verification of the required proof of compliance within the time frame or conditions of the assurance review method submitted by the manufacturer. When there has been a change in design or materials or a change in the submitted assurance review method, the manufacturer shall reapply in accordance with this paragraph. If a manufacturer fails to maintain compliance with this rule the department of health shall remove the septic tank model or the manufacturer from the list of approved septic tanks in accordance with Chapter 119. of the Revised Code.

(J) Dosing tanks shall be designed and manufactured in accordance with the following:

(1) Dosing tanks shall comply with the standards and specifications of this rule.

(2) Dosing tanks shall be selected to accommodate the volume below maximum drawdown, the maximum design dose including any drainback, and the design portion of the reserve and surge capacities as applicable. For the purposes of this chapter, reserve capacity shall be the tank capacity above alarm activation level.

(a) STS with time or demand dosed designs shall provide a reserve capacity for high water alarm events that is not less than one-half of the daily design flow.

(b) STS with time dosed designs shall accommodate combined reserve and surge capacities of not less than one hundred fifty per cent of the peak daily design flow. For the purposes of this chapter surge capacity shall be the tank volume between the high water alarm level and the maximum drawdown point level.

(c) When required by the manufacturer, the volume below maximum drawdown shall be sufficient so that the pump will remain submerged after a dosing event. For the purposes of this chapter volume below maximum drawdown shall be the volume below the pump off setting. A redundant off switch may be installed to prevent pumping below the design maximum drawdown point.

(3) A septic tank second compartment or a second septic tank in series may be used for low volume dosing if all conditions cited above are met and a filtered step system or screened vault is used in lieu of, or in addition to, the effluent filter device required.

(K) Effluent dosing pumps shall meet the following specifications:

(1) A pump shall be rated for effluent service by the manufacturer and must be third party or listed to the appropriate UL or CSA standard.

(2) The pump shall be properly sized to meet the design flow rate and total dynamic head requirements specified for the STS. The STS design shall include a graph of the pump curve showing that the pump can meet the design requirements of the network by calculation.

(3) A quick disconnect shall be accessible in the pump discharge piping with adequate lift attachments provided for removal and replacement of the pump and water level control assembly without having to either enter the dosing tank or pump the tank to lower the liquid level. When a check valve is used, a vent hole should be installed between the check valve and pump to prevent pump airlock.

(4) If any portion of the pump fittings or transport line is at a higher elevation than the soil absorption component, the system must be equipped with an air vacuum release valve or other suitable device to avoid siphoning.

(5) Replacement pumps and controls must meet the original design standards and criteria.

(L) A dosing siphon or other similar device may be used if the STS design requirements, including the design flow rate, dose capacity, and low pressure distribution parameters, can be met and maintained.

(M) Switches, controls, alarms, and electrical devices shall be listed to the appropriate UL or CSA standards, clearly and permanently labeled by the manufacturer and/or per the approved design, acceptable for the design, installed in a manner easily accessible for routine monitoring and maintenance, and shall comply with the following:

(1) Float switches, when used, must be mounted independent of the pump and transport line so that they can easily be removed from the dosing tank without disturbing or removing the pump;

(2) Except as required in paragraph (A)(5) of rule 3701-29-15.1 of the Administrative Code, controls associated with dosing of effluent shall provide a means to record dosing events or the ability to collect information to troubleshoot system malfunctions;

(3) Controls shall have both audible and visual alarms. Alarms and controls shall be on a commonly used household circuit. All other electrical components shall be on a different dedicated circuit than the alarms and controls. The board of health may require that the alarm be located in closer proximity to the dwelling or structure when the STS location is remote;

(4) Control panels and alarms shall be mounted in an easily accessible exterior location, a minimum of one foot above grade to bottom of lowest junction box and shall be field-tested to assure compliance with the STS specifications, and shall include written instructions related to standard operation and alarm events; and

(5) Failsafe shut-off mechanisms shall be required and installed for discharging off-lot systems under the household general NPDES permit and shall meet the requirements of the director's approval.

(N) The board of health may require an electrical inspection to address concerns of safety or risk of injury.

(O) STS components described in this rule shall be installed, operated and maintained as specified by the manufacturer and the approved design.

(P) Except where gray water discharges to an approved GWRS via a separate building sewer, or approved alternative toilets are used, building sewers shall carry all sewage flow from the dwelling or structure, including gray water or other segregated sewage, and shall be connected to a STS in compliance with this chapter. Building sewers shall comply with the following:

(1) The elevation of a building sewer shall be aligned to accommodate the plan elevations of the subsequent STS components at a uniform grade of not less than one per cent or one eighth of an inch per foot. Designs should avoid sewer line slopes greater than ten per cent. The sewer shall be properly bedded in in situ soil or coarse aggregate that minimizes settling;

(2) A building sewer shall be watertight, have a minimum diameter of four inches, be Schedule 40 or SDR 21 or greater, and be constructed of durable material conforming to ASTM D2661 or ASTM D1527 for ABS plastic pipe or ASTM D1785, ASTM D2729, or ASTM D2665 for PVC plastic pipe. Pipe, fittings, and joining materials shall be chemically and physically compatible and ensure water-tightness; and

(3) No pipe elbows greater than forty five degrees are permitted.

(Q) A building sewer shall allow for proper venting of STS components. Traps shall not be installed in a building sewer.

(R) A cleanout shall be required outside each structure served by a STS when one is not provided inside the structure. Additional cleanouts shall be required in a building sewer at the point a building sewer pipe exceeds seventy-five feet and at every one hundred foot interval thereafter.

(S) Casing or other form of protection shall be provided for any portion of a building sewer located in areas where soil or environmental conditions exist that could cause excessive additional loads on the sewer including vehicle traffic or excavation in or through disturbed or excavated soils.