Rule 3745-21-13 | Control of volatile organic compound emissions from reactors and distillation units employed in SOCMI chemical production.

[Comment: For dates and availability of non-regulatory government publications, publications of recognized organizations and associations, federal rules, and federal statutory provisions referenced in this rule, see paragraph (JJ) of rule 3745-21-01 of the Administrative Code titled "referenced materials."]

(A) Rule applicability.

(1) Except as otherwise provided in paragraph (A)(2) of this rule, this rule shall apply to any reactor or distillation unit in a process unit that meets both of the following criteria:

(a) The process unit is located in Ashtabula, Butler, Clermont, Cuyahoga, Geauga, Hamilton, Lake, Lorain, Medina, Portage, Summit, or Warren county.

(b) The process unit produces a SOCMI chemical.

(2) Excluded from this rule are the following:

(a) Any reactor or distillation unit that is a batch operation.

(b) Any reactor or distillation unit that is regulated by paragraph (CC) or (EE) of rule 3745-21-09 of the Administrative Code.

(c) Any reactor or distillation unit included within an "early reduction program," as specified in 40 CFR part 63, and published in 57 Federal Register 61970 (December 29, 1992), evidenced by a timely enforceable commitment approved by USEPA.

(d) Any reactor regulated by subpart III or subpart RRR of 40 CFR part 60.

(e) Any distillation unit regulated by subpart NNN of 40 CFR part 60.

(3) For the purposes of paragraph (A)(2) of this rule, a reactor or distillation unit shall be considered regulated by a paragraph, rule or subpart if the reactor or distillation unit is subject to the limits of that paragraph, rule, or subpart. A reactor or distillation unit is not considered regulated by a paragraph, rule, or subpart if the reactor or distillation unit is not subject to the limits of that paragraph, rule, or subpart. For example, if the reactor or distillation unit is covered by an exemption in the paragraph, rule, or subpart, or the applicability criteria of the paragraph or subpart are not met, then the source is not subject to that paragraph, rule, or subpart.

(B) Definitions.

The definitions applicable to this rule are contained in paragraphs (B) and (V) of rule 3745-21-01 of the Administrative Code.

(C) Overall requirements for reactors and distillation units.

(1) Except where exempted under paragraph (C)(2) of this rule, the owner or operator of a reactor or distillation unit subject to this rule shall comply with paragraphs (D) to (L) of this rule.

(2) Exempted from paragraph (C)(1) of this rule is any reactor or distillation unit in a process unit with a total design capacity for all chemicals produced within that unit of less than one thousand one hundred tons per year. However, such reactor or distillation unit remains subject to the recordkeeping and reporting requirements contained in paragraphs (J)(1)(f) and (L)(1) of this rule.

(D) Determination of group status and halogen status for process vents of reactors and distillation units.

(1) (Group status) The owner or operator of a reactor or distillation unit shall determine the group status (i.e., group 1, group 2A, or group 2B) for each process vent based on flow rate, VOC concentration, and TRE index value in accordance with paragraphs (D)(3) to (D)(5) of this rule and the procedures contained in paragraph (E) of this rule. Group 1 process vents require control for VOC, and group 2A and group 2B process vents do not. Group 1 process vents require monitoring of control devices, except for boilers or process heaters specified under paragraphs (F)(1)(b) and (F)(1)(c) of this rule, and require monitoring of bypass lines. Group 2A process vents require monitoring of the associated recovery systems, and group 2B process vents do not require any monitoring.

(2) (Halogen status) The owner or operator of a group 1 process vent which is controlled (or to be controlled) by a combustion device shall determine the halogen status in accordance with the procedures specified in paragraph (E)(7) of this rule. Group 1 process vents that are halogenated process vents being discharged to a combustion device require halogen reduction control (either a pre-combustion or post-combustion).

(3) (Group 1) A process vent shall be group 1 if it meets at least one of the following specifications:

(a) The owner or operator designates the process vent as group 1.

(b) At representative operating conditions expected to yield the lowest TRE index value for the process vent, the TRE index value is less than or equal to 1.0, the flow rate is equal to or greater than 0.30 scfm, and the VOC concentration is equal to or greater than five hundred ppmv.

(4) (Group 2A) A process vent shall be group 2A if it is from a recovery system and if, at representative operating conditions expected to yield the lowest TRE index value for the process vent, the TRE index value is greater than 1.0 and less than or equal to 4.0, the flow rate is equal to or greater than 0.30 scfm, and the VOC concentration is equal to or greater than five hundred ppmv.

(5) (Group 2B) A process vent shall be group 2B if it meets any one of the following specifications:

(a) The process vent has a flow rate less than 0.30 scfm.

(b) The process vent has a VOC concentration less than five hundred ppmv.

(c) The process vent is not from a recovery system and, at representative operating conditions expected to yield the lowest TRE index value for the process vent, the TRE index value is greater than 1.0.

(d) The process vent is from a recovery system and, at representative operating conditions expected to yield the lowest TRE index value for the process vent, the TRE index value is greater than 4.0.

(6) Process changes for group 2A and group 2B process vents.

Whenever process changes are made that could reasonably be expected to change a group 2A or group 2B process vent to a group 1 process vent, the owner or operator shall redetermine the flow rate, VOC concentration, or TRE index value, according to paragraph (D)(6)(a), (D)(6)(b), or (D)(6)(c) of this rule as specified for each process vent as necessary to determine whether the process vent is group 1, group 2A, or group 2B. The owner or operator shall perform the group status determination as soon as practical after the process change and within sixty days after the process change. Examples of process changes include, but are not limited to, changes in production capacity, production rate, feedstock type, or catalyst type, or whenever there is replacement, removal, or addition of recovery equipment. For purposes of paragraph (D)(6) of this rule, process changes do not include process upsets, unintentional, temporary process changes, and changes that are within the range on which the original TRE index value calculation was based.

(a) (Group 2B process vent based on flow rate) The flow rate shall be redetermined by using the measurement procedure in paragraph (E)(9) of this rule or by using an engineering assessment of the effects of the change.

(b) (Group 2B process based on VOC concentration) The VOC concentration shall be redetermined by using the measurement procedure in paragraph (E)(10) of this rule or by using an engineering assessment of the effects of the change.

(c) (Group 2B process vent based on TRE index value or group 2A process vent) The TRE index value shall be redetermined (recalculated) based on measurements of flow rate, net heating value, VOC emission rate, and halogen status as specified in paragraphs (E)(9), (E)(11), (E)(12), and (E)(13) of this rule, or based on an engineering assessment of the effects of the change.

(E) Procedures for process vent determinations.

(1) (General) The provisions under paragraph (E) of this rule provide procedures for the determination of process vent parameters that are used to determine the group status and halogen status for a process vent.

(2) Location within a process vent for determination of group status and halogen status and for sampling.

(a) For the purpose of determining group status of a process vent based on VOC concentration, flow rate, or TRE index value, the location shall be representative of the process vent stream after the last recovery device (if any recovery devices are present) but prior to the inlet of any control device that is present, and prior to release to the atmosphere. The process vent parameters for TRE index value are flow rate, net heating value, VOC emission rate, and halogen status.

(b) The location of the sampling site for measurement of process vent parameters (flow rate, VOC concentration, VOC emission rate, net heating value, and mass emission rate for halogen atoms) shall be selected in accordance with paragraph (E)(2)(a) of this rule and paragraph (C)(3)(f) of rule 3745-21-10 of the Administrative Code. No traverse site selection method is needed for process vents smaller than four inches (0.10 meter) in nominal inside diameter.

(3) The flow rate of a process vent shall be determined by engineering assessment or by the measurement procedure of paragraph (E)(9) of this rule.

(4) The VOC concentration of a process vent shall be determined by engineering assessment or by the measurement procedure of paragraph (E)(10) of this rule.

(5) The net heating value of a process vent shall be determined by engineering assessment or by the measurement procedure of paragraph (E)(11) of this rule.

(6) The VOC and TOC emission rate of a process vent shall be determined by engineering assessment or by the measurement procedure of paragraph (E)(12) of this rule.

(7) The halogen status of a process vent shall be determined by process knowledge that no halogen or hydrogen halides are present in the process vent, by engineering assessment, or by the measurement procedure of paragraph (E)(13) of this rule. If the mass emission rate of halogen atoms for a process vent is equal to or greater than 0.99 pound per hour, the process vent shall be classified as halogenated.

(8) Procedure for TRE index value.

The TRE index value of the process vent shall be determined as follows:

(a) TRE index value for a process vent shall be calculated by the following equation:

TRE = [a + b(Q) + c(H) + d(ETOC)] / EVOC

where:

TRE = TRE index value.

Q = Process vent flow rate, standard cubic meters per minute, at a standard temperature of 20 degrees Celsius, as determined under paragraph (E)(3) of this rule by engineering assessment or measurement procedure.

H = Process vent net heating value, megajoules per standard cubic meter, as determined under paragraph (E)(5) of this rule by engineering assessment or measurement procedure.

EVOC = Process vent emission rate of VOC, kilograms per hour, as determined under paragraph (E)(6) of this rule by engineering assessment or measurement procedure.

ETOC = Process vent emission rate of TOC, kilograms per hour, as determined under paragraph (E)(6) of this rule by engineering assessment or measurement procedure.

a, b, c, and d = coefficients presented in table A of this rule.

| Type of Process Vent Stream | Control Device Basis a | Values of Coefficients | |||

| a | b | c | d | ||

| Nonhalogenated | Flare | 2.129 | 0.183 | -0.005 | 0.359 |

| Thermal incinerator with zero per cent heatrecovery | 3.075 | 0.021 | -0.037 | 0.018 | |

| Thermal incinerator with seventy per cent heatrecovery | 3.803 | 0.032 | -0.042 | 0.007 | |

| Halogenated | Thermalincinerator and scrubber | 5.470 | 0.181 | -0.040 | 0.004 |

(b) For a nonhalogenated process vent stream, the owner or operator shall use the applicable coefficients in table A to calculate the TRE index values based on a flare, a thermal incinerator with zero heat recovery, and a thermal incinerator with seventy per cent heat recovery, and shall select the lowest TRE index value. For a halogenated process vent stream, the owner or operator shall use the applicable coefficients in table A to calculate the TRE index value based on a thermal incinerator and scrubber.

(c) If the TRE index value, as determined in accordance with paragraphs (E)(8)(a) and (E)(8)(b) of this rule, is less than or equal to 4.0, and such TRE index value is calculated using engineering assessment for process vent flow rate, process vent net heating value, process vent VOC emission rate, or process vent halogen status, then the owner or operator shall either perform the measurement procedures specified in paragraphs (E)(9), (E)(11), (E)(12), and (E)(13) of this rule for the determination of the process vent's group status or designate the process vent as a group 1 process vent.

(9) (Measurement procedure for flow rate) The process vent volumetric flow rate in standard cubic meters per minute shall be measured at a sampling site selected as specified in paragraph (E)(2)(b) of this rule and by the appropriate method specified in paragraph (C)(3)(f) of rule 3745-21-10 of the Administrative Code. If the process vent stream passes through a final steam jet ejector and is not condensed, the volumetric flow rate shall be corrected to 2.3 per cent moisture.

(10) Measurement procedure for VOC concentration.

(a) The sampling site shall be selected as specified in paragraph (E)(2)(b) of this rule.

(b) The methods and procedures under paragraph (C) of rule 3745-21-10 of the Administrative Code shall to be employed wherein USEPA method 18 or USEPA method 25A shall be employed for VOC concentration.

(c) If USEPA method 18 is employed, the following procedures shall be used:

(i) The minimum sampling time for each run shall be one hour in which either an integrated sample or four grab samples shall be taken. If grab sampling is used, then the samples shall be taken at approximately equal intervals in time, such as fifteen-minute intervals during the run.

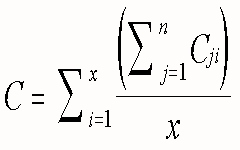

(ii) The VOC concentration (C) is the sum of the concentrations of the individual components and shall be computed for each run by the following equation:

where:

C = Concentration of VOC, dry basis, ppmv.

x = Number of samples in the sample run.

n = Number of components in the sample.

Cji = Concentration of sample component j of the sample i, dry basis, ppmv.

(d) If USEPA method 25A is employed, the following procedures shall be used:

(i) USEPA method 25A shall be used only if a single organic compound of VOC is greater than fifty per cent of the total VOC, by volume, in the process vent.

(ii) The process vent composition may be determined by either process knowledge or test data collected using an appropriate USEPA method. Examples of information that could constitute process knowledge include calculations based on material balances, process stoichiometry, or previous test results provided the results are still relevant to the current process vent conditions.

(iii) The organic compound used as the calibration gas for USEPA method 25A shall be the single organic compound of VOC present at greater than fifty per cent of the total VOC by volume.

(iv) The span value for USEPA method 25A shall be equal to five hundred ppmv.

(v) Use of USEPA method 25A is acceptable if the response from the high-level calibration gas is at least twenty times the standard deviation of the response from the zero calibration gas when the instrument is zeroed on the most sensitive scale.

(vi) The owner or operator shall demonstrate that the total organic concentration measured by USEPA method 25A is below two hundred fifty ppmv in order for the VOC concentration to be considered below five hundred ppmv.

(11) (Measurement procedure for net heating value) The net heating value of a vent stream shall be measured and calculated in accordance with 40 CFR 63.115(d)(2)(ii) and 40 CFR 63.115(d)(2)(iii).

(12) (Measurement procedure for TOC and VOC emission rates) The TOC and VOC emission rates of a process vent shall be determined in accordance with paragraph (C) of rule 3745-21-10 of the Administrative Code and the following:

(a) The sampling site shall be selected as specified in paragraph (E)(2)(b) of this rule.

(b) The minimum sampling time for each run shall be one hour in which either an integrated sample or a minimum of four grab samples shall be taken. If grab sampling is used, then the samples shall be taken at approximately equal intervals in time such as fifteen-minute intervals during the run.

(c) The mass rates of TOC and VOC for each sample shall be calculated in accordance with paragraph (C)(4) of rule 3745-21-10 of the Administrative Code wherein all organic compounds measured by USEPA method 18 are used in the calculation of the mass rate of TOC and only those organic compounds that are VOC are used in the calculation of mass rate of VOC. The mass rates of TOC and VOC for each run shall be the average of the mass rates of TOC and VOC of each sample within that run.

(13) (Measurement procedure for mass emission rate of halogen atoms) The mass emission rate of halogen atoms for a process vent shall be measured based upon a sampling site selected as specified in paragraph (E)(2)(b) of this rule, flow rate measured by the appropriate method specified in paragraph (C)(3)(f) of rule 3745-21-10 of the Administrative Code, and the halogen-related measurements and calculations specified in 40 CFR 63.115(d)(2)(v)(A)(3) and 40 CFR 63.115(d)(2)(v)(B).

(F) Control and operational requirements for process vents.

(1) For any group 1 process vent, the owner or operator shall comply with paragraph (F)(1)(a), (F)(1)(b), (F)(1)(c), (F)(1)(d), (F)(1)(e), (F)(1)(f), or (F)(1)(h) of this rule. If the group 1 process vent is a halogenated process vent that is discharged to a combustion device, the owner or operator shall also comply with paragraph (F)(1)(g) of this rule.

(a) Discharge the group 1 process vent to a flare that is designed and operated to meet paragraph (DD)(10)(d) of rule 3745-21-09 of the Administrative Code.

(b) Discharge the group 1 process vent into the flame zone of a boiler or process heater with a heat input capacity equal to or greater than one hundred fifty million Btu per hour.

(c) Discharge the group 1 process vent to a boiler or process heater as the primary fuel or with the primary fuel.

(d) Discharge the group 1 process vent to a control device (boiler, process heater, incinerator or recapture device) or combination of control devices that is designed and operated to reduce VOC emissions from the group 1 process vent by at least ninety-eight per cent or emit VOC at a concentration less than twenty ppmv, dry basis, whichever is less stringent. For a combustion device, the concentration of VOC shall be corrected to three per cent oxygen.

(e) For the group 1 process vent, achieve and maintain a TRE index value greater than 1.0 at the outlet of the final recovery device, or prior to release from the process vent to atmosphere if no recovery device is present. If the TRE index value is greater than 1.0, the process vent shall meet the requirements for a group 2A or group 2B process vent specified in paragraph (F)(2) or (F)(3) of this rule, whichever is applicable.

(f) (Existing combustion device) Discharge the group 1 process vent to a previously installed combustion device, provided all of the following conditions are met:

(i) The combustion device was installed prior to either of the following:

(a) May 27, 2005 if the facility is located in Butler, Clermont, Hamilton, or Warren county.

(b) August 25, 2008 if the facility is located in Ashtabula, Cuyahoga, Geauga, Lake, Lorain, Medina, Portage, or Summit county.

(ii) The combustion device is not capable of reliably reducing VOC emissions from the process vent in order to meet paragraph (F)(1)(d) of this rule.

(iii) The combustion control shall reduce VOC emissions from the group 1 process vent by at least ninety per cent by weight.

(iv) If the combustion device is replaced with new control equipment for which construction commenced on or after May 27, 2005 for facilities located in Butler, Clermont, Hamilton, or Warren county or August 25, 2008 for facilities located in Ashtabula, Cuyahoga, Geauga, Lake, Lorain, Medina, Portage, or Summit county, the use of paragraph (F)(1)(f) of this rule shall terminate for the group 1 process vent.

(g) A group 1 process vent that is a halogenated process vent and that is discharged to a combustion device shall be controlled with a halogen reduction device that meets paragraph (F)(1)(g)(i) or (F)(1)(g)(ii) of this rule. However, if the combustion device is a flare, the group 1 process vent shall be controlled with a halogen reduction device that meets paragraph (F)(1)(g)(ii) of this rule.

(i) (Halogen reduction device following combustion) A scrubber or other halogen reduction device that follows combustion shall meet either of the following:

(a) Except as provided in paragraph (F)(1)(g)(i)(b) of this rule, the scrubber or other halogen reduction device shall reduce overall emissions of hydrogen halides and halogens by ninety-nine per cent or shall reduce the outlet mass of total hydrogen halides and halogens to less than 0.99 pound per hour, whichever is less stringent.

(b) If a scrubber or other halogen reduction device was installed prior to May 27, 2005 for facilities located in Butler, Clermont, Hamilton, or Warren county or August 25, 2008 for facilities located in Ashtabula, Cuyahoga, Geauga, Lake, Lorain, Medina, Portage, or Summit county, the scrubber or other halogen reduction device shall reduce overall emissions of hydrogen halides and halogens by ninety-five per cent or shall reduce the outlet mass of total hydrogen halides and halogens to less than 0.99 pound per hour, whichever is less stringent.

(ii) (Halogen reduction device prior to combustion) A halogen reduction device, such as a scrubber, or other technique shall reduce the process vent's mass emission rate of halogen atoms to less than 0.99 pound per hour prior to the combustion device.

(h) (Off-site control or onsite control not owned or operated by the owner or operator of the source) Transfer the gas stream from group 1 process vent for disposal to an onsite control device (or other compliance equipment) not owned or operated by the owner or operator of the source (reactor or distillation unit) generating the gas stream, or to an off-site control device or other compliance equipment, provided the following conditions are met:

(i) The owner or operator transferring the gas stream shall do the following:

(a) Comply with the provisions specified in paragraph (H)(6) of this rule for each gas stream prior to transfer.

(b) Notify the transferee that the gas stream contains VOC that are to be treated in accordance with the provisions of this rule. The notice shall be submitted to the transferee initially and whenever there is a change in the required control.

(ii) The owner or operator may not transfer the gas stream unless the transferee has submitted to the director a written certification that the transferee will manage and treat any gas stream transferred under paragraph (F)(1)(h) of this rule and received from a source (reactor or distillation unit) subject to this rule in accordance with this rule. The certifying entity may revoke the written certification by sending a written statement to the director and the owner or operator giving at least ninety days notice that the certifying entity is rescinding acceptance of responsibility for compliance with the regulatory provisions of this rule. Upon expiration of the notice period, the owner or operator may not transfer the gas stream to the transferee. Records retained by the transferee shall be retained in accordance with paragraph (J)(1) of this rule.

(iii) By providing this written certification to the director, the certifying entity accepts responsibility for compliance with the regulatory provisions listed in paragraph (F)(1)(h)(ii) of this rule with respect to any transfer covered by the written certification. Failure to abide by any of those provisions with respect to such transfers may result in enforcement action by the director against the certifying entity.

(iv) Written certifications and revocation statements to the director from the transferees of such gas streams shall be signed by a responsible official of the certifying entity and provide the name and address of the certifying entity. Such written certifications are not transferable by the transferee.

(2) For any group 2A process vent, the owner or operator shall maintain a TRE index value greater than 1.0

(3) For any group 2B process vent, the owner or operator shall maintain a flow rate less than 0.30 scfm, or a VOC concentration less than five hundred ppmv, or a TRE index value greater than 1.0 if the gas stream is not from a recovery system, or a TRE index value greater than 4.0 if the gas stream is from a recovery system, whichever is the basis for the group 2B status for that process vent.

(G) Compliance dates.

(1) Except where otherwise specified within this rule, any owner or operator of a reactor or distillation unit that is subject to this rule shall comply with this rule by no later than the following dates:

(a) For any reactor or distillation unit located in Butler, Clermont, Hamilton, or Warren county for which installation commenced before May 27, 2005, the compliance date of the reactor or distillation unit is May 27, 2006.

(b) For any reactor or distillation unit located in Butler, Clermont, Hamilton, or Warren county for which installation commenced on or after May 27, 2005, the compliance date of the reactor or distillation unit is the date of initial startup of the reactor or distillation unit.

(c) For any reactor or distillation unit located in Ashtabula, Cuyahoga, Geauga, Lake, Lorain, Medina, Portage, or Summit county for which installation commenced before August 25, 2008, the compliance date of the reactor or distillation unit is August 25, 2009.

(d) For any reactor or distillation unit located in Ashtabula, Cuyahoga, Geauga, Lake, Lorain, Medina, Portage, or Summit county for which installation commenced on or after August 25, 2008, the compliance date of the reactor or distillation unit is the date of initial startup of the reactor or distillation unit.

(2) In the event a reactor or distillation unit has a group 1 process vent which is subject to paragraph (F)(1)(f) of this rule and the group 1 process vent is later discharged to a new control device, the compliance date of the process vent pertaining to an applicable requirement under paragraph (F)(1) of this rule is the date of first startup of the discharge of the process vent to the new control device. Until that date of first startup, the group 1 process vent shall continue to comply with paragraph (F)(1)(f) of this rule.

(3) If there is a change in group status due to a process change, the owner or operator shall meet one of the following:

(a) (Group status change to group 1) Where the process change causes the group status to change to group 1, the owner or operator shall comply with the group 1 process vent requirements in paragraph (F)(1) of this rule upon initial startup after the change and thereafter unless the owner or operator demonstrates to the director that achieving compliance will take longer than making the process change. If this demonstration is made to the director's satisfaction, the owner or operator shall comply as expeditiously as practical, but in no event later than one year after the process vent becomes a group 1 process vent, and shall comply with the following procedures to establish a compliance date:

(i) The owner or operator shall submit to the director for approval a compliance schedule, along with a justification for the schedule.

(ii) The compliance schedule shall be submitted with an application for a permit, or an application for a modification of a permit, or by other means provided by the appropriate Ohio EPA district office or local air agency.

(iii) The director shall approve the compliance schedule or request changes within ninety calendar days of receipt of the compliance schedule and justification for the schedule.

(b) (Group status change to group 2A) Where the process change causes the process vent group status to change to group 2A, the owner or operator shall comply with paragraph (F)(2) of this rule upon completion of the group status determination of the process vent.

(c) (Group status change to group 2B) Where the process change causes the process vent group status to change to group 2B or causes the basis of a group 2B status to change, the owner or operator shall comply with paragraph (F)(3) of this rule as soon as practical after the process change.

(4) The owner or operator of any reactor or distillation unit that has a group 1 process vent discharged to a flare that is designed and operated to meet paragraph (F)(1)(a) of this rule, or discharged to a control device or combination of control devices that is designed and operated to meet paragraph (F)(1)(d) of this rule shall demonstrate compliance by conducting a compliance test of the control or recovery devices in accordance with paragraph (I) of this rule within ninety days after the compliance date.

(5) The owner or operator of any reactor or distillation unit that has a group 1 process vent operated to meet paragraph (F)(1)(e) of this rule or a group 2A process vent operated to meet paragraph (F)(2) of this rule shall demonstrate compliance by conducting a TRE determination test in accordance with paragraph (I) of this rule by the compliance date.

(6) Additional testing of the process vent, control device, or recovery device of a reactor or distillation unit in accordance with paragraph (I) of this rule may be required by the director to ensure continued compliance.

(H) Monitoring for group 1 and group 2A process vents.

(1) For any flare used by a group 1 process vent to comply with paragraph (F)(1)(a) of this rule, the owner or operator shall install, calibrate, maintain, and operate according to manufacturer's specifications, a monitoring device (including but not limited to a thermocouple, ultra-violet beam sensor, or infrared sensor) capable of continuously detecting the presence of a flame.

(2) For any combustion device (boiler, process heater, incinerator) used by a group 1 process vent to comply with paragraph (F)(1)(d) or (F)(1)(g) of this rule, the owner or operator shall install, calibrate, maintain, and operate according to manufacturer's specifications, a temperature monitoring device equipped with a continuous recorder. The temperature monitoring device shall be located as follows:

(a) Where a thermal incinerator is used, the temperature monitoring device shall be located in the firebox or in the ductwork immediately downstream of the firebox in a position before any substantial heat exchange occurs.

(b) Where a catalytic incinerator is used, one of the following:

(i) Temperature monitoring devices shall be located in the gas stream immediately before (upstream) and after (downstream) the catalyst bed.

(ii) If an owner or operator elects to implement an inspection and maintenance plan for the catalytic incinerator that meets paragraph (H)(9) of this rule, the temperature monitoring device shall be located upstream of the catalyst bed only.

(c) Where a boiler or process heater is used, the temperature monitoring device shall be located in the firebox. This requirement does not apply to process vent streams that are introduced with the primary fuel or are used as the primary fuel.

(3) For any recapture device used by a group 1 process vent to comply with paragraph (F)(1)(d) of this rule and for any final recovery device within a recovery system used by a group 2A process vent to comply with paragraph (F)(2) of this rule the owner or operator shall install, calibrate, maintain and operate according to manufacturer's specifications, the following monitoring devices:

(a) Where an absorber is used, the following:

(i) A temperature monitoring device equipped with a continuous recorder shall be employed to monitor the exit temperature of the absorbing liquid.

(ii) A specific gravity monitoring device equipped with a continuous recorder shall be employed to monitor the exit specific gravity of the absorbing liquid.

(b) Where a condenser is used, a temperature monitoring device equipped with a continuous recorder shall be employed to monitor the exit (product side) temperature.

(c) Where a carbon adsorber is used, the following:

(i) An integrating regeneration stream flow monitoring device, having an accuracy of plus or minus ten per cent or better, shall be employed for recording the total regeneration stream mass or volumetric flow for each regeneration cycle.

(ii) A carbon bed temperature monitoring device shall be employed for recording the carbon bed temperature after each regeneration and within fifteen minutes of completing any cooling cycle.

(d) Where a recapture or final recovery device other than an absorber, condenser, or carbon adsorber is used, or as an alternative to the monitoring device specified in paragraphs (H)(2)(a) to (H)(2)(c) of this rule, an organic monitoring device equipped with a continuous recorder shall be employed for monitoring the concentration level or reading at the outlet of the recapture or final recovery device.

(4) For any halogen reduction device used by a halogenated group 1 process vent to comply with paragraph (F)(1)(g) of this rule, the owner or operator shall install, calibrate, maintain and operate according to manufacturer's specifications, monitoring devices as follows:

(a) Where a scrubber is used, the following monitoring devices shall be employed:

(i) A pH monitoring device equipped with a continuous recorder shall be employed to monitor the pH of the scrubber effluent.

(ii) A flow meter equipped with a continuous recorder shall be employed to monitor the scrubber influent for liquid flow.

(iii) A flow meter equipped with a continuous recorder shall be employed to monitor the gas stream flow, unless an alternative method for gas stream flow is submitted to the director, as follows:

(a) The owner or operator may determine gas stream flow using the design blower capacity, with appropriate adjustments for pressure drop.

(b) If the scrubber is subject to an Ohio EPA or USEPA regulation prior to May 27, 2005 if the facility is located in Butler, Clermont, Hamilton, or Warren county, or August 25, 2008 if the facility is located in Ashtabula, Cuyahoga, Geauga, Lake, Lorain, Medina, Portage, or Summit county, the owner or operator may determine gas stream flow by the method that had been utilized to comply with such regulation. A determination that was conducted prior to the compliance date of such regulation may be utilized to comply with this rule if the determination is still representative.

(c) The owner or operator may prepare and implement a gas stream flow determination plan that documents an appropriate method that will be used to determine the gas stream flow. The plan shall require determination of gas stream flow by a method that will at least provide a value for either a representative or the highest gas stream flow anticipated in the scrubber during representative operating conditions other than startups, shutdowns, or malfunctions. The plan shall include a description of the methodology to be followed and an explanation of how the selected methodology will reliably determine the gas stream flow and a description of the records that will be maintained to document the determination of gas stream flow.

(b) Where a halogen reduction device other than a scrubber is used, the procedures in paragraph (H)(8) of this rule shall be followed to establish monitoring devices and parameters.

(5) (Alternative parameter monitoring) An owner or operator of a process vent may request approval to employ monitoring devices and monitoring parameters other than those listed in paragraphs (H)(1) to (H)(4) of this rule. The request shall be submitted according to the procedures specified in paragraph (H)(8) of this rule. Approval shall be requested if the owner or operator uses a combustion, recovery, or recapture device other than those listed in paragraphs (H)(1) to (H)(4) of this rule or uses one of the combustion or recovery or recapture devices listed in paragraphs (H)(1) to (H)(4) of this rule, but seeks to monitor a parameter other than those specified in paragraphs (H)(1) to (H)(4) of this rule.

(6) For any bypass line that could divert a group 1 process vent directly to the atmosphere, the owner or operator shall comply with either of the following:

(a) The owner or operator shall install, calibrate, maintain, and operate, according to manufacturer's specifications, a flow indicator that takes a reading at least once every fifteen minutes. The flow indicator shall be installed at the entrance to any bypass line that could divert the gas stream to the atmosphere.

(b) The owner or operator shall secure the bypass line valve in the non-diverting position with a car-seal or a lock-and-key type configuration. The owner or operator shall perform a visual inspection of the seal or closure mechanism at least once every month to ensure that the valve is maintained in the non-diverting position and the gas stream is not diverted through the bypass line.

Equipment such as low leg drains, high point bleeds, analyzer vents, open-ended valves or lines, and pressure relief valves needed for safety purposes are not subject to this paragraph.

(7) For each parameter monitored under paragraphs (H)(2) to (H)(5) of this rule, the owner or operator shall determine a range that indicates proper operation of the control or recovery device. The ranges shall be determined in accordance with the following:

(a) If a compliance test is conducted pursuant to paragraph (I) of this rule, the range shall be based on the parameter values measured during the compliance test that demonstrated compliance and may be supplemented by engineering assessments or manufacturer's recommendations. Compliance testing is not required to be conducted over the entire range of permitted parameter values.

(b) If a TRE determination test is conducted pursuant to paragraph (I) of this rule, the range shall be based on the parameter values measured during the TRE determination test and may be supplemented by engineering assessments or manufacturer's recommendations. TRE determination testing or vent stream measurements are not required to be conducted over the entire range of permitted parameter values.

(c) If a compliance test or a TRE determination test has not been conducted, the range may be based solely on engineering assessments or manufacturer's recommendations.

In order to establish the range, the information specified under paragraph (K)(2)(c) of this rule shall be submitted as part of the initial compliance status report required under paragraph (K)(2) of this rule.

(8) Approval of other monitoring devices and parameters.

(a) The owner or operator who has been directed by any paragraph of this rule to establish monitoring devices and parameters or request approval to employ monitoring devices and parameters other than required by this rule shall submit within an application for a permit or modification of a permit, or by other means provided by the appropriate Ohio EPA or local air agency, the following information:

(i) A description of the parameter to be monitored to ensure the process, control technology, or pollution prevention measure is operated in conformance with its design and achieves the specified emission limit, percent reduction, or nominal efficiency, and an explanation of the criteria used to select the parameter.

(ii) A description of the methods and procedures that will be used to demonstrate that the parameter indicates proper operation of the control device or recovery device being monitored, the schedule for this demonstration, and a statement that the owner or operator will establish a range for the monitored parameter as part of the initial compliance status report required in paragraph (K)(2) of this rule.

(iii) The frequency and content of monitoring, recording, and reporting if monitoring and recording is not continuous, or if reports of daily average values when the monitored parameter value is outside the range established in the operating permit or initial compliance report will not be included in semiannual reports as specified in paragraph (K)(2) of this rule. The rationale for the proposed monitoring, recording, and reporting system shall be included.

(b) If the monitoring device and parameter are approved by the director, the monitoring device and parameter, including associated records and semiannual reporting, shall be specified in the terms and conditions of a permit or order issued by the director.

(9) For an owner or operator that elects, in accordance with paragraph (H)(2)(b)(ii) of this rule, to monitor the upstream temperature only of the catalytic incinerator, an inspection and maintenance plan shall be developed, maintained on-site, and made readily available upon the request of the appropriate Ohio EPA district office or local air agency. At a minumum, the plan shall include the following:

(a) Annual sampling and analysis of the catalyst activity (i.e., conversion efficiency) following the manufacturer's or catalyst supplier's recommended procedures.

(b) Monthly inspection of the oxidizer system including the burner assembly and fuel supply lines for problems.

(c) Annual internal and monthly external visual inspection of the catalyst bed to check for channeling, abrasion, and settling. If problems are found, corrective action consistent with the manufacturer's recommendations shall be implemented and a new performance test to determine destruction efficiency in accordance with paragraph (C) of rule 3745-21-10 of the Administrative Code shall be conducted.

(I) Compliance tests and TRE determination tests for group 1 and group 2A process vents.

(1) Where a flare is used to comply with paragraph (F)(1)(a) of this rule, the owner or operator shall conduct compliance tests as follows:

(a) Determine visible emissions from the flare in accordance with paragraph (DD)(10)(d)(i) of rule 3745-21-09 of the Administrative Code.

(b) Determine the net heating value of the gas being combusted in accordance with paragraph (P)(2) of rule 3745-21-10 of the Administrative Code.

(c) Determine the actual exit velocity of the flare in accordance with paragraph (P)(3) of rule 3745-21-10 of the Administrative Code

(2) No initial compliance test is required for a boiler or process heater used to comply with paragraph (F)(1)(b) or (F)(1)(c) of this rule.

(3) Except as provided in paragraph (I)(8) of this rule, any owner or operator using a control device (or combination of control devices) to comply with the VOC reduction or VOC concentration requirement in paragraph (F)(1)(d) of this rule or the VOC reduction requirement in paragraph (F)(1)(f) of this rule, shall conduct an initial compliance test as follows:

(a) For determination of compliance with the ninety or ninety-eight per cent reduction of VOC requirement, sampling sites shall be located at the outlet to atmosphere of any control device and at the inlet of the control device (or combination of control devices) as follows:

(i) The control device inlet sampling site shall be located after the final recovery device (if any).

(ii) If a vent stream is introduced with the combustion air or as a secondary fuel into a boiler or process heater with a design capacity less than one hundred fifty million Btu per hour, selection of the location of the inlet sampling sites shall ensure the measurement of VOC concentrations in all vent streams and primary and secondary fuels introduced into the boiler or process heater.

(b) For determination of compliance with the twenty ppmv VOC limit, the sampling site shall be located at the outlet of any control device.

(c) The VOC concentration and mass rate of VOC for each sampling site shall be determined in accordance with the test methods in paragraph (C) of rule 3745-21-09 of the Administrative Code as follows:

(i) VOC concentration shall be based on USEPA method 18.

(ii) The minimum sampling time for each run shall be one hour in which either an integrated sample or a minimum of four grab samples shall be taken. If grab sampling is used, then the samples shall be taken at approximately equal intervals in time such as fifteen minute intervals during the run.

(iii) The mass rate of VOC for each sample shall be calculated in accordance with paragraph (C)(4) of rule 3745-21-10 of the Administrative Code. The mass rate of VOC for each run shall be the average of the mass rate of VOC of each sample within that run.

(d) The per cent reduction of VOC shall be the per cent reduction in the mass rate of VOC between the outlet of the last recovery device and the outlet to atmosphere from all control devices combined.

(e) If a combustion device is the control device used to comply with the twenty ppmv VOC limit, the concentration of VOC shall be corrected to three per cent oxygen for each run as follows:

(i) The emission rate correction factor or excess air, integrated sampling and analysis procedures of USEPA method 3B shall be used to determine the oxygen concentration (%O2d). The samples shall be taken during the same time that the VOC samples are taken.

(ii) The concentration corrected to three per cent oxygen (Cc) shall be computed using the following equation:

Cc = Cm (17.9)/(20.9 - %02d)

where:

Cc = Concentration of VOC corrected to three per cent oxygen, dry basis, ppmv.

Cm = Concentration of VOC measured, dry basis, ppmv.

%02d = Concentration of oxygen, dry basis, per cent by volume.

(4) Any owner or operator using a combustion device followed by a scrubber or other halogen reduction device to comply with paragraph (F)(1)(g)(i) of this rule shall conduct an initial compliance test to determine compliance with the per cent reduction (control efficiency) requirement or outlet mass limit for total hydrogen halides and halogens as follows:

(a) For determining compliance with the per cent reduction requirement, sampling sites shall be located at the inlet and outlet of the scrubber or other halogen reduction device used to reduce halogen emissions.

(b) For determining compliance with outlet mass emission limit, the sampling site shall be located at the outlet of the scrubber or other halogen reduction device and prior to any releases to the atmosphere.

(c) Except as provided in paragraph (I)(4)(f) of this rule, USEPA method 26 or USEPA method 26A shall be used to determine the concentration, in milligrams per dry standard cubic meter, of total hydrogen halides and halogens that may be present in the gas stream at each sampling site. The mass emissions of each hydrogen halide and halogen compound shall be calculated from the measured concentrations and the gas stream flow rate.

(d) To demonstrate compliance with the per cent reduction requirement, the owner or operator shall do the following:

(i) Sum the mass emissions for any hydrogen halides and halogens present at the inlet of the scrubber or other halogen reduction device.

(ii) Sum the mass emissions for any hydrogen halides and halogens present at the outlet of the scrubber or other halogen reduction device.

(iii) Determine the per cent reduction by comparison of the summed inlet and outlet measurements.

(e) To demonstrate compliance with the outlet mass emission limit, the owner or operator shall sum the mass emissions for any hydrogen halides and halogens at the outlet of the scrubber or other halogen reduction device express the emissions as a mass emission rate in pounds per hour. The resultant mass emission rate of total hydrogen halides and halogens shall be less than 0.99 pound per hour.

(f) The owner or operator may use any other method to demonstrate compliance if the method or data has been validated according to the applicable procedures of USEPA method 301.

(5) An owner or operator using a scrubber or other halogen reduction device to reduce the vent stream halogen atom mass emission rate to less than 0.99 pound per hour prior to a combustion device to comply with paragraph (F)(1)(g)(ii) of this rule shall determine the halogen atom mass emission rate prior to the combustion device according to the measurement procedure in paragraph (E)(13) of this rule.

(6) Except as provided in paragraph (I)(9) of this rule, any owner or operator using a recovery system, process change, or other means to achieve and maintain a TRE index value greater than 1.0 for a process vent and to comply with paragraph (F)(1)(e) of this rule, shall conduct TRE determination tests to determine the TRE index value of the process vent based on measurements for flow rate, net heating value, VOC emission rate, and mass emission rate of halogen atoms (if needed for halogen status) as specified in the measurement procedures of paragraphs (E)(9), and (E)(11) to (E)(13) of this rule.

(7) Except as provided in paragraph (I)(9) of this rule, any owner or operator using a recovery system to maintain a TRE index value greater than 1.0 for a process vent and comply with paragraph (F)(2) of this rule, shall conduct TRE determination tests to determine the TRE index value of the process vent based on measurements conducted for flow rate, net heating value, VOC emission rate, and mass emission rate of halogen atoms (if needed for halogen status) as specified in the measurement procedures of paragraphs (E)(9), and (E)(11) to (E)(13) of this rule.

(8) An initial compliance test is not required for the following:

(a) A control device for which a test was conducted for determining compliance with a regulation promulgated by the Ohio EPA or USEPA and the test was conducted using the same methods specified in this rule and either no process changes have been made since the test, or the owner or operator can demonstrate to the satisfaction of the director that the results of the test, with or without adjustments, reliably demonstrate compliance despite process changes.

(b) A boiler or process heater burning hazardous waste for which the owner or operator has done either of the following:

(i) Been issued a final permit under 40 CFR part 270 and complies with 40 CFR part 266, subpart H.

(ii) Certified compliance with the interim status requirements of 40 CFR part 266, subpart H.

(c) A hazardous waste incinerator for which the owner or operator has been issued a final permit under 40 CFR part 270 and complies with 40 CFR part 264, subpart O, or has certified compliance with the interim status requirements of 40 CFR part 265, subpart O.

(9) An initial TRE determination test is not required for a recovery device for which a test was conducted for determining compliance with a regulation promulgated by the Ohio EPA or USEPA and the test was conducted using the same methods specified in this rule and either no process changes have been made since the test, or the owner or operator can demonstrate to the satisfaction of the director that the results of the test, with or without adjustments, reliably demonstrate compliance despite process changes.

(J) Recordkeeping.

(1) (General) All records specified under this paragraph shall be retained by the owner or operator for a period of not less than five years and shall be made available to the director or any authorized representative of the director for review during normal business hours. The following types of records are to be maintained by the owner or operator:

(a) Group status determination records for process vents.

(b) Monitoring records for group 1 and group 2A process vents.

(c) Compliance demonstration records for group 1 process vents.

(d) Compliance demonstration records for group 2A process vents.

(e) Compliance demonstration records for group 2B process vents.

(f) Records pertaining to the one thousand one hundred tons per year exemption.

(2) Group status determination records for process vents.

The owner or operator of a reactor or distillation unit subject to this rule shall maintain records used to determine the group status of each process vent. The following types of records are to be maintained:

(a) (TRE index value records) The owner or operator shall maintain records of measurements, engineering assessments, and calculations performed to determine the TRE index value of the process vent according to the procedures of paragraph (E)(8) of this rule, including those records associated with halogen vent stream determination. Documentation of engineering assessments shall include all data, assumptions, and procedures used for the engineering assessments. For any process vent not classified as group 2B based on flow rate or VOC concentration records specified in paragraphs (J)(2)(b) and (J)(2)(c) of this rule, TRE index value records are needed to document the basis for classifying a process vent as group 1, group 2A, or group 2B.

(b) (Flow rate records) Each owner or operator who elects to demonstrate that a process vent is group 2B based on a flow rate less than 0.30 scfm shall record the flow rate as measured using the measurement procedure specified in paragraph (E)(9) of this rule or as determined through engineering assessment.

(c) (VOC concentration records) Each owner or operator who elects to demonstrate that a process vent is group 2B based on a VOC concentration less than the five hundred ppmv shall record the VOC concentration as measured using the measurement procedure specified in paragraphs (E)(10) of this rule or as determined through engineering assessment.

(d) (Process change records) The owner or operator shall keep up-to-date, readily accessible records on process changes, as defined in paragraph (D)(6) of this rule, for process vents as follows:

(i) If the process vent is a group 2B process vent on the basis of the flow rate being less than 0.30 scfm, then the owner or operator shall keep records of any process changes that increase the process vent flow rate and any redetermination of the flow rate pursuant to paragraph (D)(6)(a) of this rule.

(ii) If the process vent is a group 2B process vent on the basis of the VOC concentration being less than five hundred ppmv, then the owner or operator shall keep records of any process changes that increase the VOC concentration of the process vent and any redetermination of the concentration pursuant to paragraph (D)(6)(b) of this rule.

(iii) If the process vent is a group 2B process vent on the basis of the TRE index value being greater than 4.0 for a vent stream from a recovery system, then the owner or operator shall keep records of any process changes and any redetermination (recalculation) of the TRE index value pursuant to paragraph (D)(6)(c) of this rule.

(iv) If the process vent is a group 2B process vent on the basis of the TRE index value being greater than 1.0 for a vent stream not from a recovery system, then the owner or operator shall keep records of any process changes and any redetermination (recalculation) of the TRE index value pursuant to paragraph (D)(6)(c) of this rule.

(v) If the process vent is a group 2A process vent (i.e., the TRE index value is greater than 1.0 and less than or equal to 4.0 for a vent stream not from a recovery system), then the owner or operator shall keep records of any process changes and any redetermination (recalculation) of the TRE index value pursuant to paragraph (D)(6)(c) of this rule.

(3) Monitoring records for group 1 and group 2A process vents.

For any group 1 or group 2A process vent subject to paragraph (H) of this rule, the owner or operator shall maintain monitoring records as follows:

(a) For any flare used by a group 1 process vent to comply with paragraph (F)(1)(a) of this rule, the owner or operator shall maintain the following records for the monitoring device used to continuously detect the presence of a pilot flame:

(i) Hourly records of whether the monitor was continuously operating and whether a pilot flame was continuously present during each hour.

(ii) A record on the presence of a pilot flame over the full period of the compliance test.

(iii) A record of the times and duration of all periods when the pilot flame is absent or the monitoring device is not operating.

(b) For any combustion device (boiler, process heater, or incinerator) used by a group 1 process vent to comply with paragraph (F)(1)(d) or (F)(1)(f) of this rule, the owner or operator shall maintain the following records for the temperature monitoring device:

(i) Where the combustion device is a thermal incinerator, boiler, or process heater:

(a) Continuous records of firebox temperature.

(b) A record of the firebox temperature averaged over the full period of the compliance test.

(c) A record of daily average firebox temperature for each operating day.

(d) Records of the times and durations of all periods excluded from the daily average as specified in paragraph (J)(3)(f) of this rule and any other periods during process or control operation when the monitoring device is not working.

(ii) Where the combustion device is a catalytic incinerator and the owner or operator elects to comply with paragraph (H)(2)(b)(i) of this rule:

(a) Continuous records of temperature upstream and downstream of catalyst bed.

(b) A record of the upstream temperature, downstream temperature, and temperature difference across the catalyst bed averaged over the full period of the compliance test.

(c) A record of the daily average of the upstream temperature and the temperature difference across the catalyst bed for each operating day.

(d) Records of the times and durations of all periods excluded from the daily average as specified in paragraph (J)(3)(f) of this rule and any other periods during process or control operation when the monitoring device is not working.

(iii) Where the combustion device is a catalytic incinerator and the owner or operator elects to comply with paragraphs (H)(2)(b)(ii) and (H)(9) of this rule:

(a) Continuous records of temperature upstream of the catalyst bed.

(b) A record of the upstream temperature averaged over the full period of the compliance test.

(c) A record of the daily average of the upstream temperature for each operating day.

(d) Records of the times and durations of all periods excluded from the daily average as specified in paragraph (J)(3)(f) of this rule and any other periods during process or control operation when the monitoring device is not working.

(e) Records, and a description of the results of each inspection and catalyst activity analysis.resulting from the inspection and maintenance plan for the catalytic incinerator as specified in paragraph (H)(9) of this rule.

(c) For any halogen reduction device used by a halogenated group 1 process vent to comply with paragraph (F)(1)(g)(i) of this rule, the owner or operator shall maintain the following monitoring records:

(i) Where a scrubber is employed for a halogenated vent stream following combustion:

(a) Continuous records of pH of scrubber effluent.

(b) A record of pH of the scrubber effluent averaged over the full period of the compliance test.

(c) A record of the daily average pH of the scrubber effluent for each operating day.

(d) Continuous records of scrubber liquid flow rate.

(e) A record of the scrubber liquid/gas ratio averaged over the full period of the compliance test.

(f) A record of the daily average scrubber liquid/gas ratio for each operating day.

(g) Records of the times and durations of all periods excluded from the daily average as specified in paragraph (J)(3)(f) of this rule and any other periods during process or control operation when either monitoring device is not working.

(ii) Where a halogen reduction device other than a scrubber is employed for a halogenated vent stream following combustion, the owner or operator shall maintain the monitoring records identified pursuant to paragraph (H)(8) of this rule.

(d) For any recapture device used by a group 1 process vent to comply with paragraph (F)(1)(d) of this rule and any final recovery device within a recovery system used by a group 2A process vent to comply with paragraph (F)(2) of this rule, the owner or operator shall maintain the following monitoring records, as applicable:

(i) Where an absorber is the recapture or final recovery device:

(a) Continuous records of the exit temperature of the absorbing liquid.

(b) A record of the exit temperature of the absorbing liquid averaged over the full period of the compliance test (if group 1) or averaged over the full period of the TRE index value determination (if group 2A).

(c) A record of the daily average exit temperature of the absorbing liquid for each operating day.

(d) Continuous records of the exit specific gravity.

(e) A record of the exit specific gravity averaged over the full period of the compliance test (if group 1) or averaged over the full period of the TRE index value determination (if group 2A).

(f) A record of the daily average exit specific gravity for each operating day.

(g) Records of the times and durations of all periods excluded from the daily average as specified in paragraph (J)(3)(f) of this rule and any other periods during process or control operation when either monitoring device is not working.

(ii) Where a condenser is the recapture device or final recovery device:

(a) Continuous records of the exit (product side) temperature.

(b) A record of the exit temperature averaged over the full period of the compliance test (if group 1) or averaged over the full period of the TRE index value determination (if group 2A).

(c) A record of the daily average exit temperature for each operating day.

(d) Records of the times and durations of all periods excluded from the daily average as specified in paragraph (J)(3)(f) of this rule and any other periods during process or control operation when the monitoring device is not working.

(iii) Where a carbon adsorber is the recapture device or final recovery device:

(a) A record of the total regenerative stream mass or volumetric flow for each carbon bed regeneration cycle.

(b) A record of the total regenerative stream mass or volumetric flow for each carbon bed regeneration cycle during the full period of the compliance test (if group 1) or during the full period of the TRE index value determination (if group 2A).

(c) A record of the temperature of the carbon bed after each regeneration cycle [and within fifteen minutes of completing any cooling cycle.]

(d) A record of the temperature of the carbon bed after each regeneration cycle [and within fifteen minutes of completing any cooling cycle] during the full period of the compliance test (if group 1) or during the full period of the TRE index value determination (if group 2A).

(e) Records of the times and durations of all periods during process or control operation when either monitoring device is not working.

(iv) Where an organic monitoring device is employed for monitoring the concentration level or reading at the outlet of a recapture or final recovery device other than an absorber, condenser, or carbon adsorber, or where an organic monitoring device is employed as an alternative to the otherwise specified monitoring device for an absorber, condenser, or carbon adsorber, the owner or operator shall maintain the following monitoring records:

(a) Continuous records of the concentration level or reading of the outlet of the recapture or final recovery device.

(b) A record of the concentration level or reading of the outlet of the recapture or final recovery device averaged over the full period of the compliance test (if group 1) or during the full period of the TRE index value determination (if group 2A).

(c) A record of the daily average concentration level or reading for each operating day.

(d) Records of the times and durations of all periods excluded from the daily average as specified in paragraph (J)(3)(f) of this rule and any other periods during process or control operation when the monitoring device is not working.

(e) For any bypass line that could divert a group 1 process vent directly to the atmosphere, the owner or operator shall maintain the monitoring records as follows:

(i) Where a flow indicator is employed for a bypass line:

(a) Hourly records of whether the flow indicator was operating and whether a diversion of the vent stream to the atmosphere was detected at any time during the hour.

(b) Records of the times and durations of all periods when the flow indicator is not operating or the vent stream is diverted to the atmosphere.

(ii) Where a car-seal or a lock-and-key type configuration is employed to secure the bypass line valve in the non-diverting position:

(a) A record indicating that a monthly visual inspection of the seal or closure mechanism has been done.

(b) Records of the times and durations of all periods when the seal mechanism is broken, the bypass line valve position has changed, the serial number of the broken car-seal has changed, or when the key to unlock the bypass line valve has been checked out.

(f) The daily average value of a monitored parameter shall be calculated as the average of all values recorded during the operating day by the continuous recorder, except for monitoring data recorded during the following periods:

(i) Monitoring system breakdowns, repairs, calibration checks, and zero (low-level) and high-level adjustments.

(ii) Start-ups.

(iii) Shutdowns.

(iv) Malfunctions.

(v) Periods of non-operation of the reactor or distillation unit, resulting in cessation of the emissions to which the monitoring applies.

(4) Compliance demonstration records for group 1 process vents.

Any owner or operator of a group 1 process vent shall keep an up-to-date, readily accessible record of the data specified in paragraphs (J)(4)(a) to (J)(4)(e) of this rule, as applicable, to demonstrate compliance with paragraph (F) of this rule.

(a) When using a flare to comply with paragraph (F)(1)(a) of this rule, the owner or operator shall maintain records on the following:

(i) Flare design (i.e., steam-assisted, air-assisted, or non-assisted).

(ii) The results of all visible emission readings, heat content determinations (and associated concentration measurements), and exit velocity determinations (and associated flow rate measurements) for a compliance test conducted pursuant to paragraph (I)(1) of this rule.

(iii) All periods during the compliance test when the pilot flame is absent.

(b) When using a boiler or process heater to comply with paragraph (F)(1)(b) of this rule, the owner or operator shall maintain records on the heat input capacity of the boiler or process heater and a description of the location at which the vent stream is introduced into the boiler or process heater.

(c) When using a boiler or process heater to comply with paragraph (F)(1)(c) of this rule, the owner or operator shall maintain records on the location at which the vent stream is introduced into the boiler or process heater.

(d) When using a control device (boiler, process heater, incinerator, or recapture device) to comply with paragraph (F)(1)(d) of this rule, the owner or operator shall maintain records of the following:

(i) The results of compliance tests conducted pursuant to paragraph (I)(3) of this rule.

(ii) The results of parameter monitoring during the compliance test, including results of continuous parameter monitoring averaged over the full period of the compliance test.

(iii) For a boiler or process heater, a description of the location at which the vent stream is introduced into the boiler or process heater for the compliance test. For a boiler or process heater, a description of the location at which the vent stream is introduced into the boiler or process heater for the compliance test.

(e) When using a recovery system, process change, or other means to achieve and maintain a TRE index value greater than 1.0 and to comply with paragraph (F)(1)(e) of this rule, the owner or operator shall maintain records of the TRE determination tests conducted pursuant to paragraph (I)(7) of this rule.

(f) When using a combustion device to comply with paragraph (F)(1)(f) of this rule, the owner or operator shall maintain records of the following:

(i) The date of installation of the combustion device.

(ii) Documentation on why the combustion device is not capable of reliably reducing VOC emissions from the process vent in order to meet the requirement of paragraph (F)(1)(d) of this rule, including the results of any VOC emissions testing.

(iii) Information on the combustion device pertaining to design specifications, good engineering practices, and any requirements under applicable laws, as defined under paragraph (I) of rule 3745-31-01 of the Administrative Code.

(iv) The results of compliance tests conducted pursuant to paragraph (I)(3) of this rule.

(v) The results of parameter monitoring averaged over the full period of the compliance test.

(g) When using a scrubber or other halogen reduction device following a combustion device to control a halogenated vent stream to comply with paragraph (F)(1)(g)(i) of this rule, the owner or operator shall maintain records of the following:

(i) The results of compliance tests conducted pursuant to paragraph (I)(4) of this rule.

(ii) The results of parameter monitoring averaged over the full period of the compliance test.

(h) When transferring a group 1 process vent for disposal to comply with paragraph (F)(1)(h) of this rule, the owner or operator shall maintain records on the name and location of the transferee and the identification of the group 1 process vent.

(5) Compliance demonstration records for group 2A process vents.

Any owner or operator of a group 2A process vent shall keep an up-to-date, readily accessible record of the data specified in paragraphs (J)(5)(a) to (J)(5)(b) of this rule to demonstrate compliance with paragraph (F)(2) of this rule.

(a) The results of the TRE determination test (i.e., measurements of vent stream flow rate and vent stream concentrations used in the TRE index value determination, all measured while the vent stream is normally routed and constituted).

(b) The calculations to determine the TRE index value.

(c) The results of parameter monitoring for the final recovery device (absorber, condensers, carbon adsorber, or other recovery device) during the TRE determination test, including results of continuous parameter monitoring averaged over the full period of the TRE determination test.

(6) Compliance demonstration records for group 2B process vents.

Any owner or operator of a group 2B process vent shall keep an up-to-date, readily accessible record of the data specified in paragraph (J)(6)(a), (J)(6)(b), or (J)(6)(c) of this rule, whichever is applicable, to demonstrate compliance with paragraph (F)(3) of this rule.

(a) Any owner or operator who elects to demonstrate that a process vent is a group 2B process vent based on a flow rate being less than 0.30 scfm shall maintain a record of the vent stream flow rate as determined in accordance with paragraph (E)(3) of this rule, including documentation of any engineering assessments, measurements, and calculations.

(b) Any owner or operator who elects to demonstrate that a process vent is a group 2B process vent based on a VOC concentration being less than five hundred ppmv shall maintain a record of the vent stream VOC concentration as determined in accordance with paragraph (E)(4) of this rule, including documentation of any engineering assessments, measurements, and calculations.

(c) Any owner or operator who elects to demonstrate that a process vent not from a recovery system is a group 2B process vent based on the TRE index value being greater than 1.0 shall maintain records of the following:

(i) A description and identification of the process operation or device preceding the process vent.

(ii) The TRE index value as determined in accordance with paragraph (E)(8) of this rule, including documentation of any engineering assessments, measurements, and calculations.

(d) Any owner or operator who elects to demonstrate that a process vent from a recovery system is a group 2B process vent based on the TRE index value being greater than 4.0 shall maintain records of the following:

(i) A description and identification of the final recovery device preceding the process vent.

(ii) The TRE index value as determined in accordance with paragraph (E)(8) of this rule, including documentation of any engineering assessments, measurements, and calculations.

(7) Records pertaining to the one thousand one hundred tons per year exemption.

The owner or operator of a reactor or distillation unit subject to this rule and qualifying for the exemption under paragraph (C)(2) of this rule regarding a process unit with a total design capacity for all chemicals produced within that unit of less than one thousand one hundred tons per year, shall keep up-to-date records detailing the design production capacity of the process unit, including any change in equipment or process operation that affects the total design production capacity.

(K) Reporting.

(1) (General) The provisions under paragraph (K) of this rule describe the contents of reports and identify the reporting dates for the following reports:

(a) Initial compliance status report.

(b) Semiannual compliance status reports.

(c) Process change reports for group 2A and group 2B process vents.

(2) Initial compliance status report.

Each owner or operator of a reactor or distillation unit subject to this rule shall submit an initial compliance status report within sixty calendar days after the compliance dates specified in paragraph (G) of this rule as follows:

(a) The initial compliance status report shall include the results of any process vent group determinations, compliance tests, TRE determination tests, inspections, values of monitored parameters established during compliance tests and TRE determination tests, and any other information used to demonstrate compliance and recorded pursuant to paragraphs (J)(4) to (J)(6) of this rule.

(b) For compliance tests, TRE determination tests, and any group determinations based on measurements, the initial compliance status report shall include one complete test report for each test method used for a particular kind of process vent. For additional tests and measurements performed for the same kind of process vent using the same test method, the test results or measurement results shall be submitted, but a complete test report is not required.

(c) A complete test report shall include a brief process description, sampling site description, description of sampling and analysis procedures and any modifications to standard procedures, quality assurance procedures, record of operating conditions during the test, record of preparation of standards, record of calibrations, raw data sheets for field sampling, raw data sheets for field and laboratory analyses, documentation of calculations, and any other information required by the test method.

(d) For each monitored parameter for which a range is required to be established under paragraph (H)(7) of this rule (pertains to group 1 and group 2A process vents), the compliance status report shall include the following information:

(i) The specific range of the monitored parameter for each control device and final recovery device.

(ii) The rationale for the specific range for each parameter for each control device and final recovery device, including any data and calculations used to develop the range and a description of why the range indicates proper operation of the control device or final recovery device.

(3) Semiannual compliance status reports.

The owner or operator of a reactor or distillation unit subject to this rule shall submit semiannual compliance status reports containing the information in paragraphs (K)(3)(a) to (K)(3)(c) of this rule. The semiannual compliance status reports shall be submitted no later than sixty calendar days after the end of each six-month period to the appropriate Ohio EPA district office or local air agency. The first report shall be submitted no later than eight months after the date the initial compliance status report is due and shall cover the six-month period beginning on the date the initial compliance status report is due.

(a) Semiannual reports on parameter monitoring for group 1 process vents.

For a group 1 process vent, the semiannual compliance status reports shall include the following recorded information:

(i) Reports of daily average values of monitored parameters for all operating days when the daily average values recorded under paragraph (J)(3) of this rule were outside the ranges established in the initial compliance status report or permit issued by the director.

(ii) Reports of the times and durations of all periods recorded under paragraph (J)(3) of this rule when the monitoring device is not working or monitoring data is not collected during process operation generating the process vent stream or during operation of the control or recovery device.

(iii) Reports of the times and durations of all periods recorded under paragraph (J)(3)(e)(i)(b) of this rule when the vent stream is diverted to the atmosphere through a bypass line.

(iv) Reports of the duration of all periods recorded under paragraph (J)(3)(e)(ii)(b) of this rule when the seal mechanism is broken, the bypass line valve position has changed, the serial number of the broken car-seal has changed, or the key to unlock the bypass line valve has been checked out.

(v) Reports of the times and durations of all periods recorded under paragraph (J)(3)(a)(iii) of this rule in which all pilot flames of a flare were absent.