Rule 3745-21-18 | Commercial motor vehicle and mobile equipment refinishing operations.

[Comment: For dates and availability of non-regulatory government publications, publications of recognized organizations and associations, federal rules, and federal statutory provisions referenced in this rule, see paragraph (JJ) of rule 3745-21-01 of the Administrative Code titled "referenced materials."

(A) Applicability.

(1) All commercial motor vehicle and mobile equipment refinishing operations (sources), regardless of date of construction or modification, that are located in Butler, Clark, Clermont, Greene, Hamilton, Miami, Montgomery, or Warren county shall comply with the following:

(a) Paragraphs (C)(1) and (C)(2) of this rule beginning May 1, 2009.

(b) Paragraphs (C)(3) to (C)(6) of this rule beginning April 11, 2006.

(2) All commercial motor vehicle and mobile equipment refinishing operations (sources), regardless of date of construction or modification, that are located in Ashtabula, Cuyahoga, Geauga, Lake, Lorain, Medina, Portage, or Summit county shall achieve compliance with this rule by no later than April 2, 2010.

(B) Definitions.

The definitions applicable to this rule are contained in paragraph (D) of rule 3745-21-01 of the Administrative Code.

(C) Operating requirements.

Except where exempt under paragraph (D) of this rule a person at a facility subject to this rule shall do the following:

(1) Not apply to mobile equipment or mobile equipment components any automotive pretreatment, automotive primer-surfacer, automotive primer-sealer, automotive topcoat, or automotive specialty coatings, including any VOC-containing materials added to the original coating supplied by the manufacturer, that contain VOCs in excess of the limits specified in the table of this rule:

| Coating Type | Limit (pounds VOC per gallon of coating, excluding water and exempt solvents) | Limit (grams VOC per liter of coating, excluding water and exempt solvents) |

| pretreatment primer | 6.5 | 780 |

| primer-surfacer | 4.8 | 575 |

| primer-sealer | 4.6 | 550 |

| topcoat(single-stage) | 5.0 | 600 |

| topcoat (two-stage basecoat/clearcoat) | 5.0 | 600 |

| topcoat (three or four-stage basecoat/clearcoat) | 5.2 | 625 |

| multi-colored topcoat | 5.7 | 680 |

| automotive specialty | 7.0 | 840 |

(2) Calculate the VOC content of the coatings employed in accordance with the following:

(a) Except for multi-stage topcoats, the mass of VOC per combined volume of VOC and coating solids, excluding water and exempt solvents, shall be calculated by the following equation:

VOC = (Wv - Ww - Wec)/(V - Vw - Vec)

where:

VOC = VOC content in pounds per gallon of coating, excluding water and exempt solvents.

Wv = mass of total volatiles, in pounds.

Ww = mass of water, in pounds.

Wec = mass of exempt solvents, in pounds.

V = volume of coating, in gallons.

Vw = volume of water, in gallons.

Vec = volume of exempt solvents, in gallons.

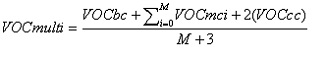

(b) The VOC content of a multi-stage topcoat shall be calculated by the following equation:

where:

VOCmulti = VOC content of multistage topcoat, in pounds per gallon, excluding water and exempt solvents.

VOCbc = VOC content of basecoat, in pounds per gallon, excluding water and exempt solvents.

VOCmci = VOC content of each midcoat, in pounds per gallon, excluding water and exempt solvents.

VOCcc = VOC content of the clear coat, in pounds per gallon, excluding water and exempt solvents.

M = number of midcoats.

(The VOC content of each coating shall be measured in accordance with USEPA method 24.)

(3) Use one or more of the following application techniques, in accordance with manufacturer's specifications, to apply any coating containing a VOC as a pretreatment, primer, sealant, basecoat, clear coat, or topcoat to mobile equipment for commercial purposes:

(a) Flow or curtain coating.

(b) Dip coating.

(c) Roller coating.

(d) Brush coating.

(e) Cotton-tipped swab application.

(f) Electro-deposition coating.

(g) HVLP spraying.

(h) Electrostatic spray.

(i) Airless spray.

(j) Air-assisted airless spray.

(k) Any other coating application method that the owner or operator of a facility or manufacturer demonstrates and Ohio EPA determines achieves emission reductions equivalent to HVLP or electrostatic spray application methods. This demonstration shall be submitted to the director for approval. Any equivalent coating application method approved by the director shall be submitted to the USEPA as a revision to the Ohio state implementation plan.

(4) Be properly trained in the use of an HVLP sprayer, or equivalent application, in accordance with manufacturer's specifications, and in the handling of a coating and any solvents used to clean the sprayer.

(5) Ensure that the spray guns used to apply mobile equipment repair and refinishing coatings are cleaned by one of the following:

(a) An enclosed spray gun cleaning system that is kept closed when not in use.

(b) Un-atomized discharge of solvent into a paint waste container that is kept closed when not in use.

(c) Disassembly of the spray gun and cleaning in a vat that is kept closed when not in use.

(d) Atomized spray into a paint waste container that is fitted with a device designed to capture atomized solvent emissions.

(6) Store the following materials in nonabsorbent, non-leaking containers and keep these containers closed at all times when not in use:

(a) Fresh coatings.

(b) Used coatings.

(c) Solvents.

(d) VOC-containing additives and materials.

(e) VOC-containing waste materials.

(f) Cloth, paper, or absorbent applicators moistened with any of the items listed in this subsection.

(D) Exemptions.

The following coating applications shall be exempt from this rule:

(1) The application of a coating for graphic designs, stenciling, lettering or other identification marking through the use of an air brush method.

(2) The application of a coating sold in a non-refillable aerosol container.

(3) The application of a coating to mobile equipment solely for repair of small areas of surface damage or minor imperfections.

(E) Record keeping and reporting.

(1) Each owner or operator subject to the provisions of this rule shall submit documentation to the appropriate Ohio EPA district office or local air agency sufficient to demonstrate that high efficiency transfer application techniques of coatings required in this rule are in use at their facility, and verify that all employees applying coatings are properly trained in the use of an HVLP sprayer, or equivalent application, and that all employees are trained in the handling of a coating and any solvents used to clean the sprayer. The owner or operator shall retain the documentation on site and make the documentation available to the appropriate Ohio EPA district office or local air agency upon request. The documentation shall be submitted by the following:

(a) June 10, 2006 for sources covered under paragraph (A)(1)(b) of this rule.

(b) June 10, 2009 for sources covered under paragraph (A)(1)(a) of this rule.

(c) No later than April 2, 2010 for sources covered under paragraph (A)(2) of this rule.

(2) Each owner or operator subject to the provisions of this rule shall maintain records for a period of five years of the amount and VOC content of each coating employed and report to the director all emissions in excess of the limits specified in the table of this rule within forty-five days after each exceedance is discovered.

Last updated June 30, 2025 at 10:19 PM