Rule 3745-21-19 | Control of volatile organic compound emissions from aerospace manufacturing and rework facilities.

[Comment: For dates and availability of non-regulatory government publications, publications of recognized organizations and associations, federal rules, and federal statutory provisions referenced in this rule, see paragraph (JJ) of rule 3745-21-01 of the Administrative Code titled "referenced materials."]

(A) Applicability.

(1) Except as otherwise provided in paragraph (A)(2) of this rule, this rule shall apply to any aerospace manufacturing or rework facility that is located in Ashtabula, Butler, Clermont, Cuyahoga, Geauga, Hamilton, Lake, Lorain, Medina, Portage, Summit, or Warren county.

(2) Excluded from this rule is any aerospace manufacturing or rework facility that has the potential to emit for VOC of less than 25.0 tons per year for all operations combined where aerospace components and vehicles are cleaned or coated. The activities, operations, and materials described in paragraphs (C)(2) and (C)(3) of this rule are not included in such determination of potential to emit for VOC.

(B) Definitions.

The definitions applicable to this rule are contained in paragraphs (B) and (AA) of rule 3745-21-01 of the Administrative Code.

(C) Overall requirements for an aerospace manufacturing or rework facility.

(1) Except as otherwise provided in paragraphs (C)(2) and (C)(3) of this rule, any owner or operator of an aerospace manufacturing or rework facility that is subject to this rule shall comply with paragraphs (D) to (L) of this rule.

(2) This rule does not apply to the following activities where cleaning and coating of aerospace components and vehicles may take place:

(a) Research and development.

(b) Quality control.

(c) Laboratory testing.

(d) Electronic parts and assemblies (except for cleaning and coating of completed assemblies).

(3) This rule does not apply to rework operations performed on antique aerospace vehicles and components.

(D) VOC emission limitations and application methods for coating operations.

(1) Except as otherwise provided in paragraphs (D)(2) and (D)(3) of this rule, a person shall not apply to aerospace vehicles or components any coating that contains VOC in excess of the following VOC content limits:

(a) VOC content limits for primers, topcoats, and chemical milling maskants.

| Type of coating | VOC content limit (pounds of VOC per gallon of coating, excluding water and exempt solvents, as applied) |

| Primer | 2.9 |

| Primer for general aviation rework facility | 4.5 |

| Exterior primer for large commercial aircraft (components or fully assembled) | 5.4 |

| Topcoat | 3.5 |

| Topcoat for general aviation rework facility | 4.5 |

| Self-priming topcoat | 3.5 |

| Self-priming topcoat for general aviation rework facility | 4.5 |

| Chemical milling maskant, type I | 5.2 |

| Chemical milling maskant, type II | 1.3 |

(b) VOC content limits for specialty coatings.

| Type of specialty coating | VC content limit (pounds of VOC per gallon of coating, excluding water and exempt solvents, as applied) |

| Ablative coating | 5.0 |

| Adhesion promoter | 7.4 |

| Adhesive bonding primer cured above two hundred fifty degrees Fahrenheit | 8.6 |

| Adhesive bonding primer cured at two hundred fifty degrees Fahrenheit or below | 7.1 |

| Antichafe coating | 5.5 |

| Bearing coating | 5.2 |

| Bonding maskant | 10.3 |

| Caulking and smoothing compounds | 7.1 |

| Chemical agent-resistant coating | 4.6 |

| Clear coating | 6.0 |

| Commercial exterior aerodynamic structure primer | 5.4 |

| Commercial interior adhesive | 6.3 |

| Compatible substrate primer | 6.5 |

| Corrosion prevention compound | 5.9 |

| Critical use and line sealer maskant | 8.5 |

| Cryogenic flexible primer | 5.4 |

| Cryoprotective coating | 5.0 |

| Cyanoacrylate adhesive | 8.5 |

| Dry lubricative material | 7.3 |

| Electric or radiation-effect coating | 6.7 |

| Electrostatic discharge and electromagnetic interference (EMI) coating | 6.7 |

| Elevated temperature Skydrol-resistant commercial primer | 6.2 |

| Epoxy polyamide topcoat | 5.5 |

| Fire-resistant (interior) coating | 6.7 |

| Flexible primer | 5.3 |

| Flight test coatings;all other | 7.0 |

| Flight test coatings: missile or single use aircraft | 3.5 |

| Fuel tank adhesive | 5.2 |

| Fuel tank coating | 6.0 |

| High temperature coating | 7.1 |

| Insulation covering | 6.2 |

| Intermediate release coating | 6.3 |

| Lacquer | 6.9 |

| Metallized epoxy coating | 6.2 |

| Mold release | 6.5 |

| Nonstructural adhesive | 3.0 |

| Optical anti-reflective coating | 6.3 |

| Part marking coating | 7.1 |

| Pretreatment coating | 6.5 |

| Rain erosion-resistant coating | 7.1 |

| Rocket motor bonding adhesive | 7.4 |

| Rocket motor nozzle coating | 5.5 |

| Rubber-based adhesive | 7.1 |

| Scale inhibitor | 7.3 |

| Screen print ink | 7.0 |

| Seal coat maskant | 10.3 |

| Sealants: extrudable, rollable, or brushable sealant | 2.3 |

| Sealants: sprayable sealant | 5.0 |

| Silicone insulation material | 7.1 |

| Solid film lubricant | 7.3 |

| Specialized function coating | 7.4 |

| Structural autoclave adhesive | 0.5 |

| Structural nonautoclavable adhesive | 7.1 |

| Temporary protective coating | 2.7 |

| Thermal control coating | 6.7 |

| Wing coating | 7.1 |

| Wet fastener installation coating | 5.6 |

(2) VOC emission control system for a coating operation.

In lieu of the VOC content limit for a coating subject to paragraph (D)(1) of this rule, a VOC emission control system shall be used that achieves, for the coating employed and designated for control, an overall reduction of VOC emissions that is equal to or greater than eighty-one per cent by weight. Also, if the VOC emission control system includes a thermal or catalytic oxidizer, the control efficiency of the thermal or catalytic oxidizer for VOC emissions shall be at least ninety per cent by weight.

(3) The following coating applications are exempt from the VOC content limits listed in paragraphs (D)(1)(a) and (D)(1)(b) of this rule:

(a) Aerosol coatings.

(b) Touchup and repair coatings.

(c) DOD classified coatings.

(d) Coating of space vehicles.

(e) Coatings that meet the following low usage restrictions at the facility:

(i) Annual total usage of each separate coating formulation does not exceed fifty gallons.

(ii) Combined annual total usage of such coating formulations does not exceed two hundred gallons.

(4) Except as otherwise provided in paragraph (D)(5) of this rule, a person shall use one or more of the following application methods for applying primers and topcoats (including self-priming topcoat) to aerospace vehicles or components:

(a) Flow/curtain applications.

(b) Dip coat application.

(c) Roll coating.

(d) Brush coating.

(e) Cotton tipped swab application.

(f) Electrodeposition (dip) coating.

(g) High volume low pressure (HVLP) spraying.

(h) Electrostatic spray application.

(i) Other coating application methods that achieve VOC emission reductions equivalent to HVLP or electrostatic spray application methods, as determined according to 40 CFR 63.750(i).

(5) The following situations are exempt from paragraph (D)(4) of this rule:

(a) Any situation that normally requires the use of an airbrush or an extension on the spray gun to properly reach limited access spaces.

(b) The application of coatings that contain fillers that adversely affect atomization with HVLP spray guns and that the permitting agency has determined cannot be applied by any of the application methods specified in paragraph (D)(4) of this rule.

(c) The application of coatings that normally have a dried film thickness of less than 0.0013 centimeter (0.0005 inch) and that the director has determined cannot be applied by any of the application methods specified in paragraph (D)(4) of this rule.

(d) The use of airbrush application methods for stenciling, lettering, and other identification markings.

(e) The use of handheld spray can application methods.

(f) Touchup and repair operations.

(E) Cleaning operations.

(1) Hand wipe cleaning operations.

(a) Except as otherwise provided in paragraph (E)(1)(b) of this rule, any cleaning solvent employed in a hand wipe cleaning operation shall meet one of the following specifications:

(i) Meet the definition of an aqueous cleaning solvent.

(ii) Have a VOC composite vapor pressure of 7.0 millimeters of mercury (3.75 inches of water) or less at twenty degrees Celsius (sixty-eight degrees Fahrenheit).

(b) The following hand wipe cleaning operations are exempt from paragraph (E)(1)(a) of this rule:

(i) Cleaning during the manufacture, assembly, installation, maintenance, or testing of components of breathing oxygen systems that are exposed to the breathing oxygen.

(ii) Cleaning during the manufacture, assembly, installation, maintenance, or testing of parts, subassemblies, or assemblies that are exposed to strong oxidizers or reducers (e.g., nitrogen tetroxide, liquid oxygen, or hydrazine).

(iii) Cleaning and surface activation prior to adhesive bonding.

(iv) Cleaning of electronic parts and assemblies containing electronic parts.

(v) Cleaning of aircraft and ground support equipment fluid systems that are exposed to the fluid, including air-to-air heat exchangers and hydraulic fluid systems.

(vi) Cleaning of fuel cells, fuel tanks, and confined spaces.

(vii) Surface cleaning of solar cells, coated optics, and thermal control surfaces.

(viii) Cleaning during fabrication, assembly, installation, and maintenance of upholstery, curtains, carpet, and other textile materials used in the interior of the aircraft.

(ix) Cleaning of metallic and nonmetallic materials used in honeycomb cores during the manufacture or maintenance of these cores, and cleaning of the completed cores used in the manufacture of aerospace vehicles or components.

(x) Cleaning of aircraft transparencies, polycarbonate, or glass substrates.

(xi) Cleaning and cleaning solvent usage associated with research and development, quality control, and laboratory testing.

(xii) Cleaning operations, using nonflammable liquids, conducted within five feet of energized electrical systems (energized electrical systems means any AC or DC electrical circuit on an assembled aircraft once electrical power is connected, including interior passenger and cargo areas, wheel wells and tail sections).

(xiii) Cleaning operations identified as essential uses under the Montreal Protocol for which the USEPA has allocated essential use allowances or exemptions in 40 CFR 82.4.

(2) Spray gun cleaning operations.

(a) Except as otherwise provided in paragraph (E)(2)(b) of this rule, any spray gun to be cleaned shall be cleaned by one or more of the following techniques:

(i) Enclosed system.

(a) Clean the spray gun in an enclosed system that is closed at all times except when inserting or removing the spray gun. Cleaning shall consist of forcing solvent through the gun.

(b) Visually inspect the seals and other potential sources of leaks associated with the enclosed system at least once per month. If leaks are found, repairs shall be made as soon as practicable, but no later than fifteen days after the leak was found. If the leak is not repaired by the fifteenth day after detection, the cleaning solvent shall be removed, and the enclosed cleaner shall be shut down until the leak is repaired or its use is permanently discontinued.

(ii) Nonatomized cleaning.

Clean the spray gun by placing cleaning solvent in the pressure pot and forcing it through the gun with the atomizing cap in place. No atomizing air is to be used. Direct the cleaning solvent from the spray gun into a vat, drum, or other waste container that is closed when not in use.

(iii) Disassembled spray gun cleaning.

Disassemble the spray gun and clean the components by hand in a vat, which shall remain closed at all times except when in use. Alternatively, soak the components in a vat, which shall remain closed during the soaking period and when not inserting or removing components.

(iv) Atomized cleaning.

Clean the spray gun by forcing the cleaning solvent through the gun and directing the resulting atomized spray into a waste container that is fitted with a device designed to capture the atomized cleaning solvent emissions.

(b) The cleaning of nozzle tips of automated spray equipment systems, except for robotic systems that can be programmed to spray into a closed container, shall be exempt from paragraph (E)(2)(a) of this rule.

(3) Flush cleaning operations.

(a) Except as otherwise provided in paragraph (E)(3)(b) of this rule, the used cleaning solvent of any flush cleaning operation shall be emptied into an enclosed container or collection system that is kept closed when not in use or captured with wipers provided they comply with the housekeeping requirements of paragraph (E)(4) of this rule.

(b) Excluded from paragraph (E)(3)(a) of this rule is any cleaning solvent that meets any of the following specifications:

(i) Meets the definition of an aqueous cleaning solvent.

(ii) Has a VOC composite vapor pressure of 7.0 millimeters of mercury (3.75 inches of water) or less at twenty degrees Celsius (sixty-eight degrees Fahrenheit).

(iii) Meets the definition of a semiaqueous cleaning solvent.

(4) Housekeeping measures for cleaning solvents and solvent-laden cleaning materials used in cleaning operations.

(a) Except for semiaqueous cleaning solvents and where excluded under paragraph (E)(4)(d) of this rule, all fresh and spent cleaning solvents shall be stored in nonabsorbent, nonleaking containers that are kept closed at all times except when filling or emptying.

(b) Except where excluded under paragraph (E)(4)(d) of this rule, all used solvent-laden cloths and papers, and any other absorbent applicators used for cleaning, shall be placed in nonabsorbent, nonleaking containers or bags that are kept closed at all times except when depositing or removing these materials from the container or bag.

(c) Except where excluded under paragraph (E)(4)(d) of this rule, the handling and transfer of cleaning solvents to or from enclosed systems, vats, waste containers, and other cleaning operation equipment that hold or store fresh or spent cleaning solvents shall be conducted in such a manner that minimizes spills.

(d) Excluded from paragraphs (E)(4)(a) to (E)(4)(c) of this rule is the use of any cleaning solvent that meets any of the following specifications:

(i) Meets the definition of an aqueous cleaning solvent.

(ii) Has a VOC composite vapor pressure of 7.0 millimeters of mercury (3.75 inches of water) or less at twenty degrees Celsius (sixty-eight degrees Fahrenheit).

(F) Compliance dates.

(1) Except where otherwise specified within this rule, any owner or operator of a facility that is subject to this rule shall comply with this rule by no later than the following dates:

(a) For an aerospace manufacturing or rework facility located in Ashtabula, Cuyahoga, Geauga, Lake, Lorain, Medina, Portage, or Summit county for which installation commenced before August 25, 2008, the compliance date is either August 25, 2009 or the date of initial startup of the aerospace manufacturing or rework facility, whichever is later.

(b) For an aerospace manufacturing or rework facility located in Ashtabula, Cuyahoga, Geauga, Lake, Lorain, Medina, Portage, or Summit county for which installation commenced on or after August 25, 2008, the compliance date is the date of initial startup of the aerospace manufacturing or rework facility.

(c) For an aerospace manufacturing or rework facility located in Butler, Clermont, Hamilton or Warren county for which installation commenced before the effective date of this rule, the compliance date is either March 1, 2023 or the date of initial startup of the aerospace manufacturing or rework facility, whichever is later.

(d) For an aerospace manufacturing or rework facility located in Butler, Clermont, Hamilton or Warren county for which installation commenced on or after the effective date of this rule, the compliance date is the date of initial startup of the aerospace manufacturing or rework facility.

(2) For a VOC emission control system that is used for a coating operation to comply with paragraph (D)(2) of this rule, the owner or operator shall demonstrate the overall control efficiency of the VOC emission control system and the control efficiency of any thermal or catalytic oxidizer within the VOC emission control system by testing the coating operation and the VOC emission control system in accordance with paragraph (I) of this rule within ninety days after the coating operation's compliance date.

(3) Additional testing of the coating operation and the VOC emission control system in accordance with paragraph (I) of this rule may be required by the director to ensure continued compliance.

(G) Monitoring requirements for a VOC emission control system.

For a VOC emission control system that is used for a coating operation to comply with paragraph (D)(2) of this rule, the owner or operator shall meet the same monitoring requirements as contained in paragraph (H) of rule 3745-21-15 of the Administrative Code.

(H) Procedures for the VOC content of a coating, the VOC content of a coating applied by a dip coater, the composition of a cleaning solvent, and the VOC composite vapor pressure of a cleaning solvent.

(1) The VOC content of a coating shall be determined by the owner or operator in accordance with paragraph (B) of rule 3745-21-10 of the Administrative Code, wherein formulation data or USEPA method 24 procedures (which include various ASTM measurement methods) may be employed.

(2) VOC content of a coating applied by a dip coater (rolling thirty-day average VOC content).

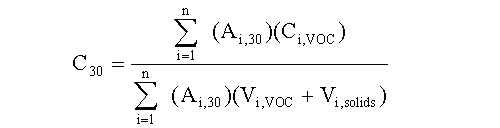

The as applied VOC content of a coating applied by a dip coater shall be determined by the owner or operator as a rolling thirty-day average of the VOC content of the material (coating and thinner) added to the reservoir of the dip coater. The rolling thirty-day average VOC content (C30), expressed in pounds of VOC per gallon of coating, excluding water and exempt solvents, as applied, shall be calculated for each day of operation of the dip coater as follows:

Where:

Ai,30 = amount of material i added to the reservoir of the dip coater during a thirty-day period consisting of the day of operation of the dip coater plus the previous twenty-nine calendar days, expressed in gallons.

Ci,VOC = VOC content of material i expressed in pounds of VOC per gallon.

Vi,solids = volume fraction of solids (nonvolatile matter) in material i.

Vi,VOC = volume fraction of VOC in material i.

i = subscript denoting a specific material (coating or thinner) added to the reservoir of the dip coater during the thirty-day period.

n = total number of materials (coatings and thinners) added to the reservoir of the dip coater during the thirty-day period.

(3) The composition of a cleaning solvent shall be based upon data supplied by the manufacturer of the cleaning solvent. The data shall identify all components of the cleaning solvent.

(4) The VOC composite vapor pressure of a cleaning solvent shall be determined by the owner or operator in accordance with paragraph (S) of rule 3745-21-10 of the Administrative Code.

(I) Compliance tests for VOC emission control systems.

(1) For a VOC emission control system used to comply with paragraph (D)(2) of this rule, the owner or operator shall conduct a compliance test to determine the capture efficiency of the capture system, the control efficiency of the control device (or each control device if a combination of control devices is employed), and the overall control efficiency of the VOC emission control system in accordance with paragraph (C) of rule 3745-21-10 of the Administrative Code wherein USEPA method 25 or 25A shall be used for determining the concentration of VOC in a gas stream.

(2) During the compliance test described in paragraph (I)(1) of this rule that demonstrates compliance, the owner or operator shall establish the operating limits (operating parameter values) for the monitoring devices required under paragraph (G) of this rule by following paragraph (J)(2) of rule 3745-21-15 of the Administrative Code.

(J) Recordkeeping.

(1) (General) All records specified under paragraph (J) of this rule shall be retained by the owner or operator for a period of not less than five years and shall be made available to the director or any authorized representative of the director for review during normal business hours. The following types of records are to be maintained by the owner or operator of an aerospace manufacturing or rework facility subject to this rule:

(a) Compliance demonstration records for coating operations.

(b) Compliance demonstration records for cleaning operations.

(c) Monitoring records for VOC emission control systems.

(2) Compliance demonstration records for coating operations.

For any coating operation subject to paragraph (D) of this rule, the owner or operator shall maintain the following records:

(a) For each coating in use at the facility, the following:

(i) The name and VOC content as received and as applied.

(ii) The type of coating, as identified in paragraphs (D)(1)(a) and (D)(1)(b) of this rule.

(iii) Where applicable, identification of the coating as designated for control pursuant to paragraph (D)(2) of this rule or exempted pursuant to paragraphs (D)(3)(a) to (D)(3)(e) of this rule.

(b) All data, calculations, and test results (including USEPA method 24 results) used in determining the VOC content of each coating, expressed in pounds of VOC per gallon of coating, excluding water and exempt solvents, as applied.

(c) The amount (gallons) of each coating used each month at the facility.

(d) For any coating operation controlled by a VOC emission control system, the following:

(i) Identification of the coating line.

(ii) Documentation on the overall control efficiency of the VOC emission control system and the control efficiency of any thermal or catalytic oxidizer within the VOC emission control system, including design estimates and the results of compliance tests conducted pursuant to paragraphs (F)(2), (F)(3), and (I) of this rule.

(iii) For any coating that is controlled by the VOC emission control system, the name of the coating, the dates (or time periods) of control, and the amount (gallons) of such coating controlled each month.

(e) Records pertaining to a rolling thirty-day average VOC content for a dip coater, the following:

(i) For each day of operation, the gallons of each material (coating and thinner) added to the dip coater reservoir.

(ii) The VOC content (in pounds of VOC per gallon), volume fraction VOC, and volume fraction solids for each material added to the dip coater reservoir.

(iii) For each day of operation, the rolling thirty-day average VOC content in pounds of VOC per gallon of coating, excluding water and exempt solvent, as applied, as determined in accordance with paragraph (H)(2) of this rule.

(f) Records pertaining to the low usage coating exemption (for coating formulations elected by the owner or operator as being subject to the low usage restrictions under paragraph (D)(3)(e) of this rule), the following:

(i) The name of each separate coating formulation.

(ii) The amount (gallons) used during the month at the facility for each separate coating formulation.

(iii) The total amount (gallons) used during the calendar year at the facility for each separate coating formulation and for all such coatings formulations combined.

(3) Compliance demonstration records for cleaning operations.

For cleaning operations subject to paragraph (E) of this rule, the owner or operator shall maintain the following records, where appropriate:

(a) The name, vapor pressure (i.e., VOC composite vapor pressure), and documentation showing the composition of each cleaning solvent used.

(b) A listing of cleaning operations in which each cleaning solvent is used.

(c) For each cleaning solvent used in hand wipe cleaning operations that complies with the water composition requirement under the paragraph (E)(1)(a)(i) of this rule or the VOC composite vapor pressure requirement under paragraph (E)(1)(a)(ii) of this rule, the following:

(i) The name of each cleaning solvent used.

(ii) All data and calculations that demonstrate the cleaning solvent complies with either the water composition requirement or VOC composite vapor pressure requirement.

(iii) The amount (gallons) of each cleaning solvent used each year, as determined from facility purchase or usage records.

(d) For each cleaning solvent used in hand wipe cleaning operations that does not comply with the requirements under paragraph (E)(1)(a) of this rule, but is exempted under paragraph (E)(1)(b) of this rule, the following:

(i) The name of each cleaning solvent used.

(ii) A list of the exempted hand wipe cleaning operations set forth in paragraph (E)(1)(b) of this rule in which each cleaning solvent is used.

(iii) The amount (gallons) of each cleaning solvent used each year, as determined from facility purchase or usage records.

(e) For each cleaning solvent used in flush cleaning operations that complies with the water composition requirement under paragraph (E)(3)(b)(i) or (E)(3)(b)(iii) of this rule or the VOC composite vapor pressure requirement under paragraph (E)(3)(b)(ii) of this rule, the following:

(i) The name of each cleaning solvent used.

(ii) All data and calculations that demonstrate the cleaning solvent complies with either the water composition requirement or VOC composite vapor pressure requirement.

(iii) The amount (gallons) of each cleaning solvent used each year, as determined from facility purchase or usage records.

(f) For any enclosed spray gun cleaner subject to paragraph (E)(2)(a)(i) of this rule, the following:

(i) A record or schedule of visual inspections of the seals and other potential sources of leaks.

(ii) For each leak found, the following:

(a) Identification of the type of leak.

(b) Date leak was discovered.

(c) Date leak was repaired.

(4) Monitoring records for VOC emission control systems.

For a VOC emission control system subject to paragraph (G) of this rule, the owner or operator shall maintain the same monitoring records as specified under paragraph (K)(5) of rule 3745-21-15 of the Administrative Code.

(K) Reporting.

(1) (General) The provisions under paragraph (K) of this rule describe the contents of reports and identify the reporting dates for the following reports:

(a) Initial compliance status.

(b) Semiannual compliance status.

(2) Initial compliance status report.

The owner or operator of an aerospace manufacturing or rework facility subject to this rule shall submit an initial compliance status report within sixty calendar days after the compliance date specified in paragraph (F) of this rule as follows:

(a) For any coating operation subject to the VOC content limit of paragraph (D)(1) of this rule, the owner or operator shall state in the initial compliance status report the type of coating, the VOC content limit for the coating, and that only coatings meeting the applicable VOC content limit are to be employed, unless otherwise controlled pursuant to paragraph (D)(2) of this rule or exempted pursuant to paragraph (D)(3) of this rule.

(b) For any coating that is applied by means of a dip coater, that is subject to the VOC content limit of paragraph (D)(1) of this rule, and that complies by the procedures of paragraph (H)(2) of this rule pertaining to a rolling thirty-day average VOC content, the owner or operator shall state in the initial compliance status report that only coatings meeting the applicable VOC content limit, as determined by the procedures of paragraph (H)(2) of this rule, are to be employed.

(c) For any coating operation that is equipped with a VOC emission control system to comply with paragraph (D)(2) of this rule, the owner or operator shall submit the following in the initial compliance status report:

(i) Information on the types of coatings to be controlled.

(ii) Identification and description of each monitoring device employed to comply with paragraph (G) of this rule.

(iii) The results of compliance tests conducted pursuant to paragraph (I) of this rule to determine the overall control efficiency of the VOC emission control system and the control efficiency of any thermal or catalytic oxidizer within the VOC emission control system.

(iv) A complete test report for any compliance tests of the VOC emission control system.

A complete test report shall include a brief process description, sampling site description, description of sampling and analysis procedures and any modifications to standard procedures, quality assurance procedures, record of operating conditions during the test, record of preparation of standards, record of calibrations, raw data sheets for field sampling, raw data sheets for field and laboratory analyses, documentation of calculations, and any other information required by the test method.

(v) For any compliance tests of the VOC emission control system, the compliance test monitoring data recorded pursuant to paragraph (I)(2) of this rule, including the operating parameter values established for any monitoring device.

(d) For cleaning operations subject to paragraph (E) of this rule, the owner or operator shall submit the following in the initial compliance status report:

(i) A description of the types of cleaning operations.

(ii) A listing of the cleaning solvents being employed in each cleaning operation.

(iii) A statement that all cleaning operations are to comply with the applicable requirements under paragraph (E) of this rule.

(3) Semiannual compliance status reports.

The owner or operator of an aerospace manufacturing or rework facility subject to this rule shall submit semiannual compliance status reports no later than thirty calendar days after the end of each six-month period to the appropriate Ohio EPA district office or local air agency. The first report shall be submitted no later than thirty calendar days after the end of the first six-month period following the compliance date. Subsequent reports shall be submitted no later than thirty calendar days after the end of each six-month period following the first report or no later than thirty calendar days after the end of each six-month period otherwise established within a permit issued for the aerospace manufacturing or rework facility. For each semiannual compliance status report, the owner or operator shall submit the following information for the six-month period covered by the report:

(a) For any coating operation subject to paragraph (D)(1) of this rule, the owner or operator shall state in the semiannual compliance status report any changes to the previous reporting of the types of coatings and the VOC content limits for the coatings.

(b) For any coating that is applied by means of a dip coater and that is subject to the VOC content limit of paragraph (D)(1) of this rule, the owner or operator shall state in the semiannual compliance status report any changes to the previous reporting of procedures for determining the VOC content of the coating.

(c) For any VOC emission control system employed to met paragraph (D)(2) of this rule, any changes to monitoring devices previously reported and required under paragraph (G) of this rule.

(d) If any subsequent compliance tests of the VOC emission control system are conducted during the semiannual reporting period after the initial compliance status report has been submitted, the semiannual compliance status report shall include the results of each compliance test, a complete test report, and the compliance test monitoring data as described under paragraphs (K)(2)(c)(iii) to (K)(2)(c)(v) of this rule.

(e) For cleaning operations subject to paragraph (E) of this rule, the owner or operator shall submit in the semiannual compliance status report any changes to the previous reporting of the description of the types of cleaning operations and the listing of the cleaning solvents employed in each cleaning operation.

(f) Compliance certification for semiannual reporting period.

The owner or operator shall submit with the semiannual compliance status report, the following compliance certifications, where applicable:

(i) For any coating that is subject to a VOC content limit of paragraph (D)(1) of this rule, the compliance certification shall state that only coatings which comply with the applicable VOC content limit have been used each operating day in the semiannual reporting period, or should otherwise identify the periods of use of coatings that did not comply, the reasons for such use of noncompliant coatings, and the amounts and VOC contents of each such noncompliant coating used. Use of a noncompliant coating is a separate violation for each day the noncompliant coating is used.

(ii) For any coating that is applied by means of a dip coater, that is subject to a VOC content limit of paragraph (D)(1) of this rule, and that complies by the procedures of paragraph (H)(2) of this rule, the compliance certification shall state that only coatings which comply with the applicable VOC content limit, as determined by the procedures of paragraph (H)(2) of this rule, have been used each operating day in the semiannual reporting period, or should otherwise identify the periods of use of coatings that did not comply, the reasons for the use of such noncompliant coatings, and the amounts and VOC contents of each such noncompliant coating used. Use of a noncompliant coating is a separate violation for each day the noncompliant coating is used.

(iii) For any coating operation that is equipped with a VOC emission control system to comply with paragraph (D)(3) of this rule:

(a) The compliance certification shall state that the three-hour block averages of the monitoring parameters recorded pursuant to paragraph (K)(5) of this rule had complied with the operating limits (operating parameter values) for the monitoring parameters established under paragraph (J)(2) of this rule during of all periods of operation of the coating operation in the semiannual reporting period; or should otherwise identify the times and durations of all periods of noncompliance and the reasons for noncompliance.

(b) The compliance certification shall identify the times and durations of all periods during coating operation or control operation when the monitoring device is not working, as recorded pursuant to paragraph (J)(3) of this rule and paragraph (K)(5) of rule 3745-21-15 of the Administrative Code.

(c) For any capture system bypass line, the compliance certification shall identify the times and durations of all periods in which the captured VOC emissions were discharged to atmosphere instead of a control device, as recorded pursuant to paragraph (J)(3) of this rule and paragraph (K)(5)(f) of rule 3745-21-15 of the Administrative Code, and the reasons for the discharges to atmosphere.

(d) The compliance certification shall state that the overall reduction and control of VOC emissions, based on the most recent compliance test conducted in accordance with paragraph (I) of this rule, has met paragraph (D)(2) of this rule for each coating designated for control during the semiannual reporting period, or should otherwise identify the periods of noncompliance and the reasons for noncompliance.

(iv) For coatings subject to the low usage exemption under paragraph (D)(3)(e) of this rule, the compliance certification shall state that the usage of these coatings during the semiannual reporting period did not exceed the annual usage restrictions for the calendar year, or should otherwise identify for each noncompliance of any annual usage restriction the reasons for the noncompliant usage and the amounts and VOC contents of the coatings used in the noncompliant usage.

(v) For cleaning operations subject to paragraph (E) of this rule, the compliance certification shall identify the following for the semiannual reporting period:

(a) Any instance where a noncompliant cleaning solvent is used for a hand wipe cleaning operation that is not exempted under paragraph (E)(1)(b) of this rule.

(b) Any instance where a noncompliant spray gun cleaning method is used.

(c) Any instance where a leaking enclosed spray gun cleaner remains unrepaired and in use for more than fifteen days.

(d) Any other instance of noncompliance with a requirement under paragraph (E) of this rule.

(e) If the cleaning operations have been in compliance for the semiannual reporting period, a statement that the cleaning operations have been in compliance with the applicable requirements.

(vi) The compliance certification shall identify and describe any corrective actions considered and implemented for any noncompliance being reported in the compliance certification.

(vii) The compliance certification shall be signed by the responsible official of a Title V facility, as defined in rule 3745-77-01 of the Administrative Code or the signatory authority under rule 3745-31-02 of the Administrative Code for a facility that is not Title V, that owns or operates the aerospace manufacturing or rework facility.

(L) Applicability notification and permit application.

(1) The owner or operator of an aerospace manufacturing or rework facility that is subject to this rule, is located in located in Ashtabula, Cuyahoga, Geauga, Lake, Lorain, Medina, Portage, or Summit county, and has an initial startup of coating or cleaning operations before August 25, 2008 shall notify the appropriate Ohio EPA district office or local air agency in writing that the facility is subject to this rule not later than October 24, 2008, providing the information specified in paragraph (L)(5) of this rule.

(2) The owner or operator of an aerospace manufacturing or rework facility that is subject to this rule, is located in Ashtabula, Cuyahoga, Geauga, Lake, Lorain, Medina, Portage, or Summit county, and has an initial startup of coating or cleaning operations on or after August 25, 2008 shall notify the appropriate Ohio EPA district office or local air agency in writing that the facility is subject to this rule not later than either the date of initial startup of the facility's coating or cleaning operations or October 24, 2008 (whichever is later), providing the information specified in paragraph (L)(5) of this rule. The application for a permit-to-install under rule 3745-31-02 of the Administrative Code may be used to fulfill the notification requirements of this paragraph.

(3) The owner or operator of an aerospace manufacturing or rework facility that is subject to this rule, is located in Butler, Clermont, Hamilton or Warren county, and has an initial startup of coating or cleaning operations before the effective date of this rule shall notify the appropriate Ohio EPA district office or local air agency in writing that the facility is subject to this rule not later than sixty days after the effective date of this rule, providing the information specified in paragraph (L)(5) of this rule.

(4) The owner or operator of an aerospace manufacturing or rework facility that is subject to this rule, is located in Butler, Clermont, Hamilton or Warren county, and has an initial startup of coating or cleaning operations on or after the effective date of this rule shall notify the appropriate Ohio EPA district office or local air agency in writing that the facility is subject to this rule not later than either the date of initial startup of the facility's coating or cleaning operations or sixty days after the effective date of this rule (whichever is later), providing the information specified in paragraph (L)(5) of this rule. The application for a permit-to-install under rule 3745-31-02 of the Administrative Code may be used to fulfill the notification requirements of this paragraph.

(5) The notification required in paragraphs (L)(1) to (L)(4) fo this rule shall provide the following information:

(a) Name and address of the owner or operator.

(b) Address (i.e., physical location) of the facility.

(c) Equipment description and Ohio EPA application number (if assigned) of any coating or cleaning operations.

(d) Identification of the applicable requirements, the means of compliance, and the compliance date for the coating and cleaning operations under this rule.

(e) An application for an operating permit or an application for a modification to an operating permit in accordance with Chapter 3745-77 of the Administrative Code (for sources subject to the Title V permit program) or an application for a permit-to-install and operate or an application for a modification to a permit-to-install and operate in accordance with Chapter 3745-31 of the Administrative Code (for sources not subject to the Title V permit program) for each subject process that meets one of the following:

(i) The process does not possess an effective operating permit or permit-to-install and operate.

(ii) The process possesses an effective operating permit or permit-to-install and operate and the owner or operator cannot certify in writing to the director that such subject process is in compliance with this rule. An application for an operating permit or permit-to-install and operate is not required provided the subject process is operating under an effective permit and certifies compliance. Such certification shall include all compliance certification requirements under paragraph (K)(2) of this rule.

Last updated June 25, 2025 at 6:34 PM