Rule 3745-21-20 | Control of volatile organic emissions from shipbuilding and ship repair operations (marine coatings).

[Comment: For dates and availability of non-regulatory government publications, publications of recognized organizations and associations, federal rules, and federal statutory provisions referenced in this rule, see paragraph (JJ) of rule 3745-21-01 of the Administrative Code titled "referenced materials."]

(A) Applicability.

(1) Except as otherwise provided in paragraph (A)(2) of this rule, this rule shall apply to any facility that meets both of the following conditions:

(a) The facility has shipbuilding or ship repair operations.

(b) The facility is located in Ashtabula, Butler, Clermont, Cuyahoga, Geauga, Hamilton, Lake, Lorain, Medina, Portage, Summit, or Warren county.

(2) Excluded from this rule is any facility that has the potential to emit for VOC of less than 25.0 tons per year for all shipbuilding and ship repair operations combined. However, this exclusion is not available for any facility that has, or once had, the potential to emit for VOC of equal to or greater than 25.0 tons per year for all shipbuilding and ship repair operations combined on or after the facility's compliance date specified under paragraph (F) of this rule.

(B) Definitions.

The definitions applicable to this rule are contained in paragraphs (B) and (BB) of rule 3745-21-01 of the Administrative Code.

(C) Overall requirements for shipbuilding or ship repair operations.

Any owner or operator of shipbuilding or ship repair operations that are subject to this rule shall comply with paragraphs (D) to (L) of this rule.

(D) VOC emission limitations for marine coatings.

(1) Except as otherwise provided in paragraphs (D)(2) and (D)(3) of this rule, a person shall not apply any marine coating that contains VOC in excess of the VOC content limits specified in the following table:

| Category of Marine Coating | Pounds of VOC per gallon of coating, excluding water and exemptsolvents, as applied | Pounds of VOCper gallon of solids, as applied, if the temperature is equal to or greaterthan forty degrees Fahrenheit | Poundsof VOC per gallon of solids, as applied, if the temperature is less than fortydegrees Fahrenheitb |

| General use coating | 2.8 | 4.8 | 6.1 |

| Specialty coating: | |||

| Air flask coating | 2.8 | 4.8 | 6.1 |

| Antenna coating | 4.4 | 12.0 | N/A |

| Antifoulant coating | 3.3 | 6.4 | 8.1 |

| Heat resistant coating | 3.5 | 7.0 | 8.9 |

| High-gloss coating | 3.5 | 7.0 | 8.9 |

| High-temperature coating | 4.2 | 10.3 | 13.3 |

| Inorganic zinc (high-build) coating | 2.8 | 4.8 | 6.1 |

| Interior coating | 2.8 | 4.8 | 6.1 |

| Military exterior coating | 2.8 | 4.8 | 6.1 |

| Mistcoating | 5.1 | 18.7 | N/A |

| Navigational aids coating | 4.6 | 13.3 | N/A |

| Nonskid coating | 2.8 | 4.8 | 6.1 |

| Nuclear coating | 3.5 | 7.0 | 8.9 |

| Organic zinc coating | 3.0 | 5.3 | 6.7 |

| Pretreatment coating | 6.5 | 92.6 | N/A |

| Repair and maintenance thermoplasticcoating | 4.6 | 13.3 | N/A |

| Rubbercamouflage coating | 2.8 | 4.8 | 6.1 |

| Sealantcoating for thermal spray aluminum | 5.1 | 18.7 | N/A |

| Special marking coating | 4.1 | 9.8 | N/A |

| Tackcoating | 5.1 | 18.7 | N/A |

| Undersea weapons systems coating | 2.8 | 4.8 | 6.1 |

| Weld-through preconstruction primer | 5.4 | 24.1 | N/A |

a The limits are expressed in two sets of equivalent units in the second and third columns of the table. Either set of limits may be used for the compliance procedure described in paragraph (H)(4)(a) of this rule, but only the limits expressed in units of pounds of VOC per gallon of solids (non-volatiles) shall be used for the compliance procedures described in paragraphs (H)(4)(b), (H)(4)(c), and (H)(5) of this rule.

b The limits in the fourth column of the table apply during cold-weather time periods, as defined under paragraph (BB) of rule 3745-21-01 of the Administrative Code. Cold-weather allowances are not given to coatings in categories that permit more than a forty per cent VOC content by volume. Such coatings are subject to the limits in second and third columns of the table in this rule regardless of weather conditions.

(2) VOC emission control system for a coating.

In lieu of the VOC content limit for any coating subject to paragraph (D)(1) of this rule, a VOC emission control system shall be used that achieves, for each coating employed and designated for control, an overall reduction of VOC emissions that is equal to or greater than the required overall control efficiency determined in accordance with paragraph (H)(5) of this rule. Also, if the VOC emission control system includes a thermal or catalytic oxidizer, the control efficiency of the thermal or catalytic oxidizer for VOC emissions shall be at least ninety per cent by weight.

(3) The following coating applications are exempt from the VOC content limits listed in paragraph (D)(1) of this rule:

(a) Aerosol coatings.

(b) Unsaturated polyester resin (i.e., fiberglass lay-up) coatings (however, coatings applied to suitably prepared fiberglass surfaces for protective or decorative purposes are subject to this rule).

(c) Coatings that meet the following low usage restrictions at the facility:

(i) Total usage of each separate coating formulation does not exceed fifty gallons per rolling twelve month period.

(ii) Total usage of all such coating formulations combined does not exceed two hundred fifty gallons per rolling twelve month period.

(E) Handling and transfer of marine coatings and thinners.

Any owner or operator of shipbuilding or ship repair operations shall ensure the following:

(1) All handling and transfer of marine coatings and thinners to and from containers, tanks, vats, drums, and piping systems is conducted in a manner that minimizes spills.

(2) All containers, tanks, vats, drums, and piping systems are free of cracks, holes, and other defects and remain closed unless materials are being added to or removed from them.

(F) Compliance dates.

(1) Except where otherwise specified within this rule, any owner or operator of shipbuilding or ship repair operations that are subject to this rule shall comply with this rule by no later than the following dates:

(a) For shipbuilding or ship repair operations located in Ashtabula, Cuyahoga, Geauga, Lake, Lorain, Medina, Portage, or Summit county for which installation commenced before August 25, 2008, the compliance date is either August 25, 2009 or the date of initial startup of the shipbuilding or ship repair operations, whichever is later.

(b) For shipbuilding or ship repair operations located in Ashtabula, Cuyahoga, Geauga, Lake, Lorain, Medina, Portage, or Summit county for which installation commenced on or after August 25, 2008, the compliance date is the date of initial startup of the shipbuilding or ship repair operations.

(c) For shipbuilding or ship repair operations located in Butler, Clermont, Hamilton or Warren county for which installation commenced before the effective date of this rule, the compliance date is either March 1, 2023 or the date of initial startup of the shipbuilding or ship repair operations, whichever is later.

(d) For shipbuilding or ship repair operations located in Butler, Clermont, Hamilton or Warren county for which installation commenced on or after the effective date of this rule, the compliance date is the date of initial startup of the shipbuilding or ship repair operations.

(2) For a VOC emission control system that is used for a coating to comply with paragraph (D)(2) of this rule, the owner or operator shall demonstrate the overall control efficiency of the VOC emission control system and the control efficiency of any thermal or catalytic oxidizer within the VOC emission control system by testing the coating operation and the VOC emission control system in accordance with paragraph (I) of this rule within ninety days after the compliance date of the shipbuilding or ship repair operations.

(3) Additional testing of the coating operation and the VOC emission control system in accordance with paragraph (I) of this rule may be required by the director to ensure continued compliance.

(G) Monitoring of a VOC emission control system.

For a VOC emission control system that is used for a coating to comply with paragraph (D)(2) of this rule, the owner or operator shall meet the same monitoring requirements as contained in paragraph (H) of rule 3745-21-15 of the Administrative Code.

(H) Procedures for the VOC content and solids content of a coating and the determination of required overall control efficiency for controlled coatings.

(1) The VOC content and solids content of a coating shall be determined by the owner or operator in accordance with paragraph (B) of rule 3745-21-10 of the Administrative Code, wherein formulation data or USEPA method 24 procedures (which include various ASTM measurement methods) may be employed.

(2) For each batch of coating that is received by the facility, the owner or operator shall do the following:

(a) Determine the coating category and the applicable VOC limit as specified under in paragraph (D)(1) of this rule.

(b) Certify the as supplied VOC content of the batch of coating. The owner or operator may use a certification supplied by the manufacturer for the batch, although the owner or operator retains liability should subsequent testing reveal a violation. If the owner or operator performs the certification testing, only one of the containers in which the batch of coating was received is required to be tested.

(3) In lieu of testing each batch of coating, as applied, the owner or operator may determine compliance with the VOC content limits using any combination of the procedures described in paragraphs (H)(4)(a) to (H)(4)(c) of this rule. The procedure used for each coating shall be determined and documented prior to application. However, the results of any compliance demonstration conducted by the owner or operator or any regulatory agency using USEPA method 24 shall take precedence over the results using the procedures in paragraphs (H)(4)(a), (H)(4)(b), and (H)(4)(c) of this rule.

(4) Compliance procedures for as applied VOC content of coatings.

(a) Coatings to which thinning solvent will not be applied.

For coatings to which thinning solvent (or any other material) will not be added under any circumstance or to which only water is added, the owner or operator shall comply as follows:

(i) Certify the as applied VOC content of each batch of coating.

(ii) Notify the persons responsible for applying the coating that no thinning solvent may be added to the coating by affixing a label to each container of coating in the batch or through another means.

(iii) If the certified as applied VOC content of each batch of coating used during any day is less than or equal to the applicable VOC content limit in paragraph (D)(1) of this rule (either in terms of pounds of VOC per gallon of coating, excluding water and exempt solvents, or pounds of VOC per gallon of solids), then compliance is demonstrated for each day, unless non compliance is determined using USEPA method 24.

(b) Coatings to which thinning solvent will be added (coating-by-coating compliance).

For a coating to which thinning solvent is routinely or sometimes added, the owner or operator shall comply as follows:

(i) Prior to the first application of each batch, designate a single thinner for the coating and calculate the maximum allowable thinning ratio (or ratios, if the coating shall comply with the cold-weather limits in addition to the other limits specified in paragraph (D)(1) of this rule for each batch as follows:

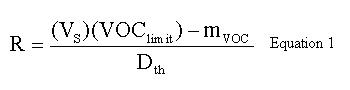

where:

R = Maximum allowable thinning ratio for a given batch (gallons of thinner per gallon of coating as supplied).

VS = Volume fraction of solids in the batch as supplied (gallon of solids per gallon of coating as supplied).

VOClimit = Maximum allowable as-applied VOC content of the coating (pound VOC per gallon of solids).

mVOC = VOC content of the batch as supplied [pounds VOC (including cure volatiles) per gallon of coating (including water and exempt compounds) as supplied].

Dth = Density of the thinner (pounds per gallon).

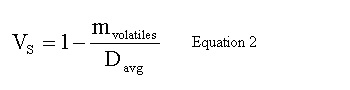

If VS is not supplied directly by the coating manufacturer, the owner or operator shall determine VS as follows:

where:

mvolatiles = Total volatiles in the batch, including VOC, water, and exempt compounds (pounds of volatiles per gallon of coating).

Davg = Average density of volatiles in the batch (pounds per gallon).

(ii) Prior to the first application of each batch, notify painters and other persons, as necessary, of the designated thinner and maximum allowable thinning ratio for each batch of the coating by affixing a label to each container of coating or through another means.

(iii) By the fifteenth day of each calendar month, determine the volume of each batch of the coating used, as supplied, during the previous month.

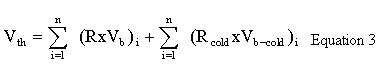

(iv) By the fifteenth day of each calendar month, determine the total allowable volume of thinner for the coating used during the previous month as follows:

Where:

Vth = Total allowable volume of thinner for the previous month (gallons of thinner).

Vb = Volume of each batch, as supplied and before being thinned, used during non-cold-weather days of the previous month (gallons of coating as supplied).

Rcold = Maximum allowable thinning ratio for each batch used during cold-weather days (gallons of thinner per gallon of coating as supplied).

Vb-cold = Volume of each batch, as supplied and before being thinned, used during cold-weather days of the previous month (gallons of coating as supplied).

i = Each batch of coating.

n = Total number of batches of the coating.

(v) By the fifteenth day of each calendar month, determine the volume of thinner actually used with the coating during the previous month.

(vi) If the volume of thinner actually used with the coating [paragraph (H)(4)(b)(v) of this rule] is less than or equal to the total allowable volume of thinner for the coating [paragraph (H)(4)(b)(iv) of this rule], then compliance is demonstrated for the coating for each operating day of the previous month, unless a violation is revealed using USEPA method 24.

(c) Coatings to which the same thinning solvent will be added (group compliance).

For coatings to which the same thinning solvent (or other material) is routinely or sometimes added, the owner or operator shall comply as follows:

(i) Designate a single thinner to be added to each coating during the month and "group" coatings according to their designated thinner.

(ii) Prior to the first application of each batch, calculate the maximum allowable thinning ratio (or ratios, if the coating shall comply with the cold-weather limits in addition to the other limits specified in paragraph (D)(1) of this rule) for each batch of coating in the group using the equations in paragraph (H)(4)(b) of this rule.

(iii) Prior to the first application of each "batch," notify painters and other persons, as necessary, of the designated thinner and maximum allowable thinning ratio for each batch in the group by affixing a label to each container of coating or through another means described in the implementation plan specified in paragraph (J)(2)(a) of this rule.

(iv) By the fifteenth day of each calendar month, determine the volume of each batch of the group used, as supplied, during the previous month.

(v) By the fifteenth day of each calendar month, determine the total allowable volume of thinner for the group for the previous month using equation 3 in paragraph (H)(4)(b)(iv)of this rule.

(vi) By the fifteenth day of each calendar month, determine the volume of thinner actually used with the group during the previous month.

(vii) If the volume of thinner actually used with the group [paragraph (H)(4)(c)(vi) of this rule] is less than or equal to the total allowable volume of thinner for the group [paragraph (H)(4)(c)(v) of this rule], then compliance is demonstrated for the group for each operating day of the previous month, unless a violation is revealed using USEPA method 24.

(d) A violation revealed through any approved test method shall result in a one-day violation for enforcement purposes. A violation revealed through the recordkeeping procedures described in paragraphs (H)(4)(c)(i) to (H)(4)(c)(iii) of this rule shall result in a thirty-day violation for enforcement purposes, unless the owner or operator provides sufficient data to demonstrate the specific days during which noncompliant coatings were applied.

(5) Determination of required overall control efficiency for controlled coatings.

For a VOC emission control system that is used to comply with paragraph (D)(2) of this rule, the overall reduction of VOC emissions, that is, the required overall control efficiency (R), expressed in per cent by weight, shall be determined as follows for each coating designated for control:

R = [(C-L)/C](100)

Where:

C = VOC content of the coating designated for control, in pounds of VOC per pound of solids, as applied; and

L = VOC content limit under paragraph (D)(1) of this rule for the coating designated for control, in pounds of VOC per pound of solids, as applied.

(I) Compliance tests for VOC emission control systems.

(1) For a VOC emission control system used to comply with paragraph (D)(2) of this rule, the owner or operator shall conduct a compliance test to determine the capture efficiency of the capture system, the control efficiency of the control device (or each control device if a combination of control devices is employed), and the overall control efficiency of the VOC emission control system in accordance with paragraph (C) of rule 3745-21-10 of the Administrative Code wherein USEPA method 25 or 25A shall be used for determining the concentration of VOC in a gas stream.

(2) During the compliance test described in paragraph (I)(1) of this rule that demonstrates compliance, the owner or operator shall establish the operating limits (operating parameter values) for the monitoring devices required under paragraph (G) of this rule by following paragraph (J)(2) of rule 3745-21-15 of the Administrative Code.

(J) Recordkeeping.

(1) (General) All records specified under paragraph (J) of this rule shall be retained by the owner or operator for a period of not less than five years and shall be made available to the director or any authorized representative of the director for review during normal business hours. The following types of records are to be maintained by the owner or operator of shipbuilding or ship repair operations subject to this rule:

(a) Compliance demonstration records for coating operations.

(b) Compliance demonstration records for the handling and transfer of marine coatings and thinners.

(c) Monitoring records for VOC emission control systems.

(2) Compliance demonstration records for coating operations.

For any coating operation subject to paragraph (D)(1) of this rule, the owner or operator shall compile the following records on a monthly basis:

(a) A copy of an implementation plan that addresses the coating compliance procedures under paragraph (H) of this rule and the recordkeeping procedures under paragraph (J) of this rule, including the procedures for gathering the necessary data and making the necessary calculations.

(b) For coating formulations elected by the owner or operator as being subject to the low usage restrictions under paragraph (D)(3)(c) of this rule, the following:

(i) The identification and gallons used during the month for each separate coating.

(ii) The total gallons used during the current rolling twelve month period (this month plus the previous eleven months) for each separate coating.

(iii) The total gallons used during the current rolling twelve month period (this month plus the previous eleven months) for all such coatings combined.

(c) Identification of the coatings used, their appropriate coating categories, and the applicable VOC limit.

(d) Certification of the as-supplied VOC content of each batch of coating.

(e) A determination of whether containers meet the requirements as described in paragraph (E)(2) of this rule.

(f) The results of any USEPA method 24 measurement test or approved alternative measurement test conducted on individual containers of coating, as applied.

(g) The records specified under paragraphs (J)(3) and (J)(4) of this rule, where appropriate.

(3) The records required by paragraph (J)(2) of this rule shall include the following additional information, as determined by the compliance procedures described in paragraph (H)(4) of this rule that each owner or operator followed:

(a) Coatings to which thinning solvent will not be added.

The records maintained by an owner or operator demonstrating compliance using the procedure described in paragraph (H)(4)(a) of this rule shall contain the following information:

(i) Certification of the as-applied VOC content of each batch of coating.

(ii) The volume of each coating applied.

(b) For coatings to which thinning solvent will be added for coating-by-coating compliance.

The records maintained by an owner or operator demonstrating compliance using the procedure described in paragraph (H)(4)(b) shall contain the following information:

(i) The density and mass fraction of water and exempt compounds of each thinner and the volume fraction of solids (nonvolatiles) in each batch, including any calculations.

(ii) The maximum allowable thinning ratio (or ratios, if the coating operation complies with the cold-weather limits in addition to the other limits specified in paragraph (D)(1) of this rule for each batch of coating, including calculations.

(iii) If an owner or operator chooses to comply with the cold-weather limits, the dates and times during which the ambient temperature at the coating operation was below forty degrees Fahrenheit (4.5 degrees Celsius) at the time the coating was applied and the volume used of each batch of the coating, as supplied, during these dates.

(iv) The volume used of each batch of the coating, as supplied.

(v) The total allowable volume of thinner for each coating, including calculations.

(vi) The actual volume of thinner used for each coating.

(c) Coatings to which the same thinning solvent will be added for group compliance.

The records maintained by an owner or operator demonstrating compliance using the procedure described in paragraph (H)(4)(c) of this rule shall contain the following information:

(i) The density and mass fraction of water and exempt compounds of each thinner and the volume fraction of solids in each batch, including any calculations.

(ii) The maximum allowable thinning ratio (or ratios, if the coating operation complies with the cold-weather limits in addition to the other limits specified in paragraph (D)(1) of this rule) for each batch of coating, including calculations.

(iii) If an owner or operator chooses to comply with the cold-weather limits, the dates and times during which the ambient temperature at the coating operation was below forty degrees Fahrenheit (4.5 degrees Celsius) at the time the coating was applied and the volume used of each batch in the group, as supplied, during these dates.

(iv) Identification of each group of coatings and their designated thinners.

(v) The volume used of each batch of coating in the group, as supplied.

(vi) The total allowable volume of thinner for the group, including calculations.

(vii) The actual volume of thinner used for the group.

(4) For any coating operation controlled by a VOC emission control system to meet paragraph (D)(2) of this rule, the owner or operator shall maintain the following records:

(a) Documentation on the overall control efficiency of the VOC emission control system and the control efficiency of any thermal or catalytic oxidizer within the VOC emission control system, including design estimates and the results of compliance tests conducted pursuant to paragraphs (F)(2), (F)(3), and (I) of this rule.

(b) The following records on a monthly basis for any coating controlled by the VOC emission control system:

(i) The identification of the coating, and the dates (or time periods) of control.

(ii) For controlled coatings to which the owner or operator does not add thinning solvents, the owner or operator shall record the certification of the as supplied and as applied VOC content of each batch and the volume of each coating applied.

(iii) For controlled coatings to which the owner or operator adds thinning solvent on a coating-by-coating basis, the owner or operator shall record all of the information required to be recorded by paragraph (J)(3)(b) of this rule.

(iv) For controlled coatings to which the owner or operator adds thinning solvent on a group basis, the owner or operator shall record all of the information required to be recorded by paragraph (J)(3)(c) of this rule.

(c) The monitoring records specified under paragraph (J)(6) of this rule.

(5) Compliance demonstration records for the handling and transfer of marine coatings and thinners.

For the handling and transfer of marine coatings and thinners, the owner or operator shall maintain the following records on a monthly basis:

(a) A copy of an implementation plan that addresses the procedures for ensuring compliance with the requirements for handling and transfer of marine coatings and thinners under paragraph (E) of this rule.

(b) A determination on whether the requirements as described in paragraph (E)(2) of this rule are being met.

(6) Monitoring records for VOC emission control systems.

For a VOC emission control system that is employed to meet paragraph (D)(2) of this rule, the owner or operator shall maintain the same monitoring records as specified under paragraph (K)(5) of rule 3745-21-15 of the Administrative Code.

(K) Reporting.

(1) (General) The provisions under paragraph (K) of this rule describe the contents of reports and identify the reporting dates for the following reports:

(a) Initial compliance status report.

(b) Semiannual compliance status reports.

(2) Initial compliance status report.

The owner or operator of shipbuilding or ship repair operations subject to this rule shall submit an initial compliance status report within sixty calendar days after the compliance date specified in paragraph (F) of this rule as follows:

(a) For any coating operation subject to the VOC content limit of paragraph (D)(1) of this rule, the owner or operator shall state in the initial compliance status report the type of coating, the VOC content limit for the coating, and that only coatings meeting the applicable VOC content limit are to be employed, unless otherwise controlled pursuant to paragraph (D)(2) of this rule or exempted pursuant to paragraph (D)(3) of this rule.

(b) For the handling and transfer of marine coatings and thinners, the owner or operator shall provide an implementation plan that addresses the procedures for ensuring compliance with the requirements under paragraph (E) of this rule.

(c) For any coating operation that is equipped with a VOC emission control system to comply with paragraph (D)(2) of this rule, the owner or operator shall submit in the initial compliance status report:

(i) Information on the types of coatings to be controlled.

(ii) Identification and description of each monitoring device employed to comply with paragraph (G) of this rule.

(iii) The results of compliance tests conducted pursuant to paragraph (I) of this rule to determine the overall control efficiency of the VOC emission control system and the control efficiency of any thermal or catalytic oxidizer within the VOC emission control system.

(iv) A complete test report for any compliance tests of the VOC emission control system.

A complete test report shall include a brief process description, sampling site description, description of sampling and analysis procedures and any modifications to standard procedures, quality assurance procedures, record of operating conditions during the test, record of preparation of standards, record of calibrations, raw data sheets for field sampling, raw data sheets for field and laboratory analyses, documentation of calculations, and any other information required by the test method.

(v) For any compliance tests of the VOC emission control system, the compliance test monitoring data recorded pursuant to paragraph (I)(2) of this rule, including the operating parameter values established for any monitoring device.

(3) Semiannual compliance status reports.

The owner or operator of shipbuilding or ship repair operations subject to this rule shall submit semiannual compliance status reports no later than thirty calendar days after the end of each six month period to the appropriate Ohio EPA district office or local air agency. The first report shall be submitted no later than thirty calendar days after the end of the first six month period following the compliance date. Subsequent reports shall be submitted no later than thirty calendar days after the end of each six month period following the first report or no later than thirty calendar days after the end of each six month period otherwise established within a permit issued for the shipbuilding or ship repair operations. For each semiannual compliance status report, the owner or operator shall submit the following information for the six month period covered by the report:

(a) For any coating operation subject to paragraph (D)(1) of this rule, the owner or operator shall state in the semiannual compliance status report any changes to the previous reporting of the types of coatings and the VOC content limits for the coatings.

(b) For the handling and transfer of marine coatings and thinners, the owner or operator shall provide any change to the implementation plan identified in paragraph (K)(2)(b) of this rule that addresses the procedures for ensuring compliance with the requirements under paragraph (E) of this rule.

(c) For any VOC emission control system employed to meet paragraph (D)(2) of this rule, any changes to monitoring devices previously reported and required under paragraph (G) of this rule.

(d) If any subsequent compliance tests of the VOC emission control system are conducted during the semiannual reporting period after the initial compliance status report has been submitted, the semiannual compliance status report shall include the results of each compliance test, a complete test report, and the compliance test monitoring data as described under paragraphs (K)(2)(c)(iii) to (K)(2)(c)(v) of this rule.

(e) The owner or operator shall submit with the semiannual compliance status report, the following compliance certifications, where applicable:

(i) For any coating that is subject to a VOC content limit of paragraph (D)(1) of this rule, the compliance certification shall state that only coatings that comply with the applicable VOC content limit have been used each operating day in the semiannual reporting period, or should otherwise identify the periods of use of coatings that did not comply, the reasons for such use of noncompliant coatings, and the amounts and VOC contents of each such noncompliant coating used. Use of a noncompliant coating is a separate violation for each day the noncompliant coating is used.

(ii) For the handling and transfer of marine coatings and thinners, the owner or operator provide any changes to the implementation plan that addresses the procedures for ensuring compliance with the requirements under paragraph (E) of this rule and shall submit information on any deviations from the implementation plan or paragraph (E) of this rule.

(iii) For any coating operation that is equipped with a VOC emission control system to comply with paragraph (D)(2) of this rule:

(a) The compliance certification shall state that the three-hour three hour block averages of the monitoring parameters recorded pursuant to paragraph (K)(5) of rule 3745-21-15 of the Administrative Code had complied with the operating limits (operating parameter values) for the monitoring parameters established under paragraph (J)(2) of this rule during of all periods of operation of the coating operation in the semiannual reporting period; or should otherwise identify the times and durations of all periods of noncompliance and the reasons for noncompliance.

(b) The compliance certification shall identify the times and durations of all periods during coating operation or control operation when the monitoring device is not working, as recorded pursuant to paragraph (J)(6) of this rule and paragraph (K)(5) of rule 3745-21-15 of the Administrative Code.

(c) For any capture system bypass line, the compliance certification shall identify the times and durations of all periods in which the captured VOC emissions were discharged to atmosphere instead of a control device, as recorded pursuant to paragraph (J)(6) of this rule and paragraph (K)(5)(f) of rule 3745-21-15 of the Administrative Code, and the reasons for the discharges to atmosphere.

(iv) The compliance certification shall state that the overall reduction and control of VOC emissions, based on the most recent compliance test conducted in accordance with paragraph (I) of this rule, has met paragraph (D)(2) of this rule for each coating designated for control during the semiannual reporting period, or should otherwise identify the periods of noncompliance and the reasons for noncompliance.

(v) For coatings subject to the low usage exemption under paragraph (D)(3)(c) of this rule, the compliance certification shall state that the usage of these coatings during the semiannual reporting period did not exceed the usage restrictions, or should otherwise identify for each noncompliance of any usage restriction the reasons for the noncompliant usage and the amounts and VOC contents of the coatings used in the noncompliant usage.

(vi) The compliance certification shall identify and describe any corrective actions considered and implemented for any noncompliance being reported in the compliance certification.

(vii) The compliance certification shall be signed by the responsible official of a Title V facility, as defined in rule 3745-77-01 of the Administrative Code or the signatory authority under rule 3745-31-02 of the Administrative Code for a facility that is not Title V, that owns or operates the shipbuilding or ship repair operations.

(L) Applicability notification and permit application.

(1) The owner or operator of a shipbuilding or ship repair operation that is subject to this rule, is located in located in Ashtabula, Cuyahoga, Geauga, Lake, Lorain, Medina, Portage, or Summit county, and has an initial startup of shipbuilding or ship repair operations before August 25, 2008 shall notify the appropriate Ohio EPA district office or local air agency in writing that the facility is subject to this rule not later than October 24, 2008, providing the information specified in paragraph (L)(5) of this rule.

(2) The owner or operator of a shipbuilding or ship repair operation that is subject to this rule, is located in Ashtabula, Cuyahoga, Geauga, Lake, Lorain, Medina, Portage, or Summit county, and has an initial startup of shipbuilding or ship repair operations on or after August 25, 2008 shall notify the appropriate Ohio EPA district office or local air agency in writing that the facility is subject to this rule not later than either the date of initial startup of the facility's coating operations or October 24, 2008 (whichever is later), providing the information specified in paragraph (L)(5) of this rule. The application for a permit-to-install under rule 3745-31-02 of the Administrative Code may be used to fulfill the notification requirements of this paragraph.

(3) The owner or operator of a shipbuilding or ship repair operation that is subject to this rule, is located in Butler, Clermont, Hamilton or Warren county, and has an initial startup of shipbuilding or ship repair operations before the effective date of this rule shall notify the appropriate Ohio EPA district office or local air agency in writing that the facility is subject to this rule not later than sixty days after the effective date of this rule, providing the information specified in paragraph (L)(5) of this rule.

(4) The owner or operator of a shipbuilding or ship repair operation that is subject to this rule, is located in Butler, Clermont, Hamilton or Warren county, and has an initial startup of shipbuilding or ship repair operations on or after the effective date of this rule shall notify the appropriate Ohio EPA district office or local air agency in writing that the facility is subject to this rule not later than either the date of initial startup of the facility's coating operations or sixty days after the effective date of this rule (whichever is later), providing the information specified in paragraph (L)(5) of this rule. The application for a permit-to-install under rule 3745-31-02 of the Administrative Code may be used to fulfill the notification requirements of this paragraph.

(5) The notification required in paragraphs (L)(1) to (L)(4) of this rule shall provide the following information:

(a) Name and address of the owner or operator.

(b) Address (i.e., physical location) of the facility.

(c) Equipment description and Ohio EPA application number (if assigned) of any coating operations.

(d) Identification of the applicable requirements, the means of compliance, and the compliance date for the coating operations under this rule.

(e) An application for an operating permit or an application for a modification to an operating permit in accordance with Chapter 3745-77 of the Administrative Code (for sources subject to the Title V permit program) or an application for a permit-to-install and operate or an application for a modification to a permit-to-install and operate in accordance with Chapter 3745-31 of the Administrative Code (for sources not subject to the Title V permit program) for each subject process that meets one of the following:

(i) The process does not possess an effective operating permit or permit-to-install and operate.

(ii) The process possesses an effective operating permit or permit-to-install and operate and the owner or operator cannot certify in writing to the director that such subject process is in compliance with this rule. An application for an operating permit or permit-to-install and operate is not required provided the subject process is operating under an effective permit and certifies compliance. Such certification shall include all compliance certification requirements under paragraph (K)(2) of this rule.

Last updated June 26, 2025 at 10:32 AM